Precisely monitor the temperature of your concrete structures under any conditions

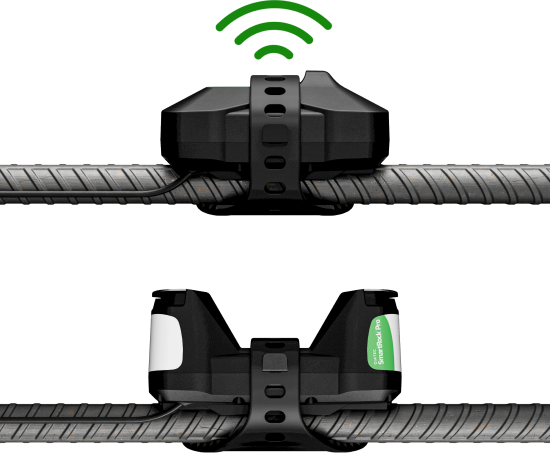

Collect real-time in-situ concrete strength data through maturity-based sensors

Maturity-Based Concrete Strength Monitoring

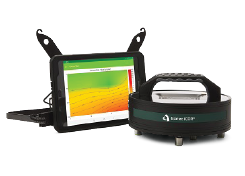

Self-Calibrating Concrete Strength Monitoring

AI-powered precision for every concrete mix for the Producers

Instant ROI

AI-Powered Decision Making

Drive Sustainability

Core Quality Control

Corrosion detection in concrete reinforcement

Concrete quality detection lab equipment

Experts revolutionizing the construction industry

Stay on the cutting edge of concrete tech

Save the date and join us at future events and conferences

Concrete mixers are essential machines in the construction industry, designed to combine cement, aggregates (like sand or gravel), and water to form concrete. This mixture is crucial for building structures, pavements, and other infrastructure. Understanding the different types of concrete mixers and their specific applications can help in selecting the right equipment for a project. In this blog, let’s explore the various types of concrete mixers, their uses, and key factors to consider for your construction project’s needs. Types of Concrete MixersBatch MixersA concrete batch mixer is a machine that helps mix different materials like cement, sand, gravel, and water to make concrete. These mixers ensure that the ingredients are blended evenly to create strong and durable concrete for construction projects like buildings, roads, and bridges. There are two main types of concrete batch mixers: stationary batch mixers and mobile batch mixers. Stationary mixers are used in concrete plants where large amounts of concrete are made and then transported to construction sites. Mobile mixers, also called transit mixers, are mounted on trucks and mix the concrete while traveling to the site, so it stays fresh and ready to use. Concrete batch mixers can be manual, semi-automatic, or fully automatic. In manual mixers, workers…

The concrete industry has long been known for its slow adoption of new technologies. While this caution may serve to maintain traditional methods, it leaves ready-mix operations vulnerable to a major digital-age challenge: cybersecurity. As the industry embraces digital tools and AI-driven solutions, many businesses find themselves unprepared to tackle the cybersecurity threats that follow. Another factor contributing to this challenge is the lack of awareness about cybersecurity practices among employees. Without proper training and protocols, businesses risk falling victim to cyberattacks that can disrupt their operations and compromise sensitive data. People are often considered the weakest link in cybersecurity, especially employees who are less familiar with digital tools and practices. For instance, concrete truck drivers who may not engage with technology as frequently can become more vulnerable to cyber threats. This blog explores cybersecurity challenges for concrete producers and outlines strategies to improve security in today’s digital landscape.The Security Gap in Technology AdoptionReady-mix concrete companies face unique cybersecurity challenges as they integrate new technologies into their operations. Many businesses have outdated systems, which can be easy targets for cybercriminals. Additionally, the industry’s fragmented nature often leads to inconsistent security practices across different teams and locations. Moreover, employees in the concrete sector…

Road construction can be a lengthy, disruptive process. So, ensuring that your project stays on schedule is one of your most important responsibilities as a project manager. Even before groundwork can begin, the planning stages of some roadways require months of soil analysis by engineers. Public consultation can also be a factor in road-building plans that pushes back schedules. While they do take time to complete, these activities are crucial in defining the scope of the project and assessing potential risks. In this blog, learn how curing sensors can help evaluate concrete pavement strength.Once the planning stage is complete, contractors bid on the job. With a winning bid selected, further land surveying begins. Geographical obstacles are removed, and the foundation of the roadway can be cut, filled, and compacted with different layers of soil and aggregate material. This process ensures that the pavement will have a stable surface to sit on.At this point, drainage systems and electrical infrastructure can be put in place before the pavement material is laid.Asphalt is the chosen pavement material for many road construction projects due to its low cost. However, concrete is becoming increasingly popular for a number of reasons:In short, concrete roads are a…

Visit our careers page to learn about our award-winning culture and our open positions.

The concrete game has changed. Find out what self-calibrating sensors can do for you with Giatec’s SmartRock® Pro.