For project managers and contractors, there is nothing more frustrating than when a job is running behind schedule. Not only does it eat into your profits, it also impacts your company’s reputation. Frequent delays on site are a very common problem in the industry. According to KPMG International’s Global Construction Project Owner’s Survey “only 25% of projects come within 10% of their original deadlines”. Delays are often blamed by a number of different factors, including; unavailable resources, improper material handling, poor productivity, equipment breakdowns, and poor work quality resulting in rework (Paul Netscher). Therefore, despite your best efforts to organize a carefully planned project schedule, many of these setbacks are out of your control. A frequent cause of delays on jobsites, that is often overlooked, is the time-consuming process of testing the compressive strength of concrete.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

The Gruelling Process of Concrete Cylinder Testing

If your latest project is anything like the majority of other concrete construction job sites, we’re betting you use break tests to monitor the strength of your in-situ slab. You probably know then that this practice requires some patience. Concrete cylinder testing has been a fixture on jobsites since the 19th century. Despite that, little to no progress has been made to speed up this process. Advancements in Internet technology and smart devices have changed the way we do almost everything, from driving a car to listening to music. But we are still using a method that pre-dates the invention of the telephone.

Whether you are choosing to follow ASTM guidelines for standard-cured or field-cured cylinders, both processes require specimens to be transported to a third-party lab at some point for compression testing. Depending on the location of your project and the lab, it can take nearly two days before someone makes their way to your jobsite to pick up these specimen. And that’s only the first in a series of steps associated with traditional cylinder testing. You then have to wait even longer to hear back from the lab to know if your concrete has reached the required strength.

If you are an experienced worker in the industry, then you probably already know that concrete often reaches its strength gain much earlier than anticipated. It can even take as little as twelve hours. If your concrete hasn’t hit that strength threshold by the time the first cylinder specimens are crushed on day three, you have to wait an additional four days before the lab will perform another strength test on day seven. During this entire tedious process, construction often completely stops onsite while workers wait for the go ahead to move on to the next steps, such as formwork removal or tensioning.

This is where your frustration with cylinder strength testing lies. Knowing that your team could be getting a lot of work done but not being able to give them the go ahead until you have those results in your hands. While you may think that this is one of the causes of delays on your jobsite that is out of your control, it doesn’t have to be.

If Not Concrete Cylinder Testing, Then What?

While alternative strength practices, such as the pull-out test, ultrasonic pulse velocity method, or rebound hammer can be used, these practices are often considered not as reliable and accurate as cylinder testing. That is why more and more project managers and contractors are turning to wireless concrete maturity sensors. Not only does this method allow you to reduce your reliance on third-party labs, you are notified in real-time what the strength of your concrete is.

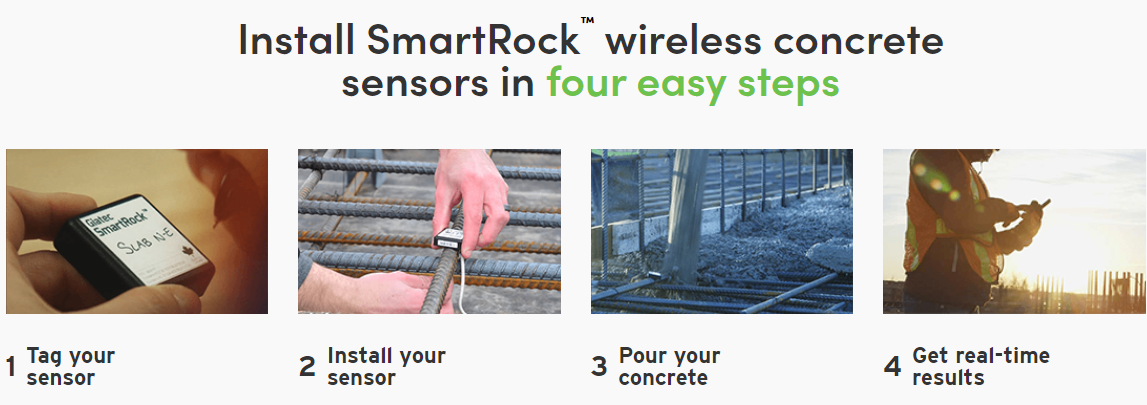

With maturity sensors, this data is accurate and reliable as the sensors are subject to the same curing conditions as the in-situ concrete slab. Fully embedded in the concrete and secured on the rebar before pouring, the temperature of your concrete is constantly monitored with these wireless sensors. Data is then used to automatically calculate compressive strength based on the maturity index. This means you know right away when your concrete is strong enough to move on to the next steps in the construction process, without waiting for results to come back from a third-party lab. The process of using the maturity method is also easy, it only takes four steps before you start receiving notifications about your concrete’s compressive strength.

Wanting to reduce their reliance on break tests and avoid the hassle of time-consuming labs was the exact reason S&F Concrete Contractors turned to wireless maturity sensors during the construction of a 28-storey Wynn Hotel and Casino in Boston, Massachusetts. Once Project Manager Steve Pirrello saw that SmartRock® sensors provided similar, if not more accurate, results when compared to break tests, they “didn’t look back.” Eliminating break tests entirely by the time they reached the fifth floor of the high-rise, Pirrello and his team were more than comfortable relying on sensor readings. In fact, they were able to schedule tensioning of slabs within an hour of the concrete achieving the required strength, instead of waiting a minimum of 24 hours for break test results.

Once the sensors were set up, we didn’t look back.

– Steve Pirrello, Project Manager, S&F Concrete Contractors

Learn more about the S&F Concrete Contractor team’s experience with SmartRock® Here

Keeping your project on schedule to meet your promised completion time is no easy task. You can always try to add more men on site to speed up the process and approve over time, but this will end up costing you more, and is not always feasible. So why not tackle some of the problems associated with delays and rethink the way you are monitoring the strength of your in-situ concrete element. Learn more about our wireless maturity sensors, SmartRock®, and prevent unnecessary delays on your job site today.

Sources:

Paul Netscher

Global Construction Project Owner Survey