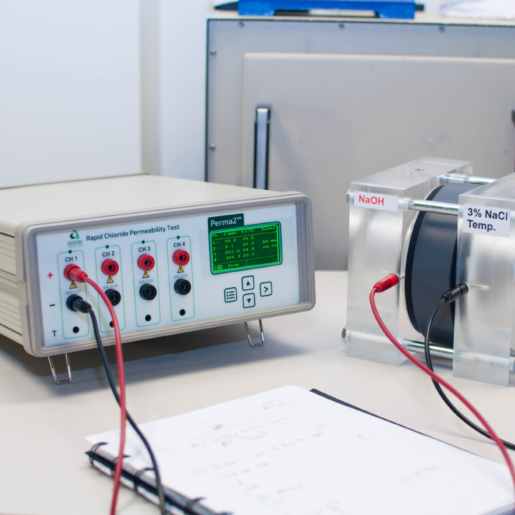

Perma™

Rapid Chloride Permeability Testing

Laboratory device for measuring the penetration of chloride in concrete

Laboratory device for measuring the penetration of chloride in concrete

Four Measurement Channels

Obtain accurate and reliable data on concrete service-life.

Flexible Logging Intervals

Customize specific testing times with Perma’s easy-to-use software.

Customizable Setup

Conveniently set up control keys to easily perform the bulk electrical resistivity test.

Perma is a laboratory device for measuring the electrical resistance of concrete against the penetration of chloride (RCPT). This data is used to estimate the chloride diffusion coefficient of concrete for predicting service life, durability-based design, and durability-based quality control, of concrete structures. Perma is electrically certified for rapid chloride penetrability tests in concrete laboratories. This device is the only RCPT device that has a CSA electrical safety certification mark for use in concrete laboratories.

Applications

AASHTO T277 – Standard Method of Test for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration

ASTM C1760 – Standard Test Method for Bulk Electrical Conductivity of Hardened Concrete

ASTM C1202 – Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration

| Type | Value |

| Measurement Channels | 4 |

| Range of Current Measurements | 0 ~ 500 mA ± 0.1 mA |

| Temperature Measurement Range | 0 ~ 100°C |

Chloride Permeability Charge

| Chloride Penetration | 56-Day Rapid Chloride Permeability Charge |

| High | >4000 |

| Moderate | 2000-4000 |

| Low | 1000-2000 |

| Very Low | 100-1000 |

| Negligible | <100 |

| Part No. | Item | Description |

| 900070 | Perma Rapid Chloride Permeability Test – Full Package-115V | Perma unit, Four set of test cells , For set of temperature sensors, Four pairs of test cables, Power cord, USB cable, User manual, Communication software, Standard Sample Preparation Package-115V, Verification Kit, Traceable certificate of calibration |

| 900073 | Perma Rapid Chloride Permeability Test – Full Package-230V | Perma unit, Four set of test cells , For set of temperature sensors, Four pairs of test cables, Power cord, USB cable, User manual, Communication software, Standard Sample Preparation Package-230V, Verification Kit, Traceable certificate of calibration |

| 900071 | Perma Test Package | Perma™ unit, Four set of test cells , For set of temperature sensors, Four pairs of test cables, Power cord, USB cable, User manual, Communication software, Verification Kit, Traceable certificate of calibration |

| 900042 | Sample Preparation Package-115V | Vacuum pump, Vacuum desiccator (single outlet, ID 24 cm, 8.8L), Vacuum gauge, Vacuum and water hosing setup |

| 900043 | Sample Preparation Package-230V | Vacuum pump, Vacuum desiccator (single outlet, ID 24 cm, 8.8L), Vacuum gauge, Vacuum and water hosing setup |

| 900103 | Enhanced Preparation Package-115V | Vacuum pump, Vacuum desiccator(double outlet, ID 35 cm, 10L), Vacuum gauge, Vacuum and water hosing set up |

| 900104 | Enhanced Preparation Package-230V | Vacuum pump, Vacuum desiccator(double outlet, ID 35 cm, 10L), Vacuum gauge, Vacuum and water hosing set up |

The following replacement parts are available upon request:

| Part No. | Item | Description |

| 900072 | Perma Device | Perma unit, Four set of temperature sensors, Four pairs of test cables, Power cord, USB cable, User manual, Communication software |

| 900064 | Verification Kit | Verification kit is required to verify the test results |

| 900021 | Test Cell | Plexiglas holder, Rubber gasket cast (4″ Dia), Stainless steel mesh, Plastic spacer,Bolts, Nuts |

| 900027 | Stainless Steel Mesh – Pair | 5 in (130 mm) diameter |

| 900028 | Rubber Gasket Cast – Pair | 4 in (100 mm) diameter |

| 900039 | Rubber Gasket Core – Pair | 3.75 in (95 mm) diameter |

| 900022 | Test Cable Set | Test cable with banana male plug |

| 900023 | Temperature Sensor | Digital temperature sensor |

| 900024 | Vacuum Pump Assembly-115 | Vacuum pump, Vacuum gauge |

| 900025 | Vacuum Pump Assembly-230 | Vacuum pump, Vacuum gauge |

| 900026 | Vacuum Desiccator Assembly | Vacuum desiccator, Vacuum and water hosing setup |

| 900027 | Enhanced Vacuum Desiccator Assembly | Vacuum desiccator (double outlet, ID 35 cm, 10L), Digital vacuum gauge, Vacuum and water hosing setup |

The NTB-492 is a popular test across Europe and other parts of the world. It is a similar test to a combination of ASTM C1202 and ASTM C1556. ASTM C1202 and NTB-492 will both provide the indication of the quality of your concrete and its ability to prevent chloride penetration. ASTM C1202 is a quicker test and slightly less complicated.

The Perma is not compliant with the NTB 492 because with this equipment you cannot change the applied voltage used in the test.

The Perma device is designed to be compliant for the ASTM C1202 and ASTM C1760 which both have fixed test time duration. ASTM C1202 requires for a 6h of testing and the testing time is not adjustable unless stopped manually at an earlier time. ASTM C1760 requires a maximum of 60 seconds test duration.

The test cells require some maintenance after each use. The environment of the test makes the cell prone to corrosion.

In order to clean the cell, one must:

No, each channel has one, but it is 16–bit. Based on ASTM C1202, the accuracy requirement 16 bit is more than enough, and our unit has the resolution 10 times better than the standard requirement.

No, this feature is not available in stand-alone operation (device only). However, if controlled through the software on a computer all this information is available to the user.

No, the device utilizes a USB B (printer cable). When controlled via a computer, all the information is saved on the computer and is accessible to the user.

ASTM C1202 applies for cylinder specimens that have a nominal diameter ranging from 95 to 100 mm. If the end-user has a sample smaller than 100 mm, he can use epoxy around the rubber gasket. The epoxy should be placed where the gap/space is located. The intention to use epoxy is to seal the test cell from leakage. In addition, as long as all gaps are closed, the test can be performed without any further issues.

If the specimen is not 95 mm in diameter, you must adjust the results based on the diameter of the sample tested according to ASTM C1202 section 11.2.

After filling the cells with the solution (NaOH and NaCl), the user must perform a leakage test.

Control the level of liquids inside each container. If the level of the liquids is not constant within ten minutes, or if any dripping is observed below the cell, there may be a leak between the gasket and the specimen surface or between the test cell and connectors. Any leakage problem should be fixed before starting the test.

If the leakage is between the gasket and the specimen surface, try tightening the bolts and refilling the cell containers. If the source of the leakage is between the cell and connectors, try tightening the connector, if it is possible. Otherwise, use silicon glue to seal the space between the connector and the cell. You may also need to adjust the position of the rubber gaskets and ensure they are properly located within the Plexiglas cell part to fix the leakage problem.

According to the ASTM C1202, a vacuum pressure of 50 mm Hg should be applied. This is equivalent to a maximum of about -28 in Hg on the pressure gauge supplied with the Perma2 vacuum pump. So, it is required to keep the pressure using the vacuum pump supplied, less than -28 in Hg during the conditioning of the RCPT specimens.

Caulking is not needed for Perma testing cell, but the specimen should have epoxy coating, in order to keep the chloride penetration one-dimensional.

The concrete game has changed. Find out what self-calibrating sensors can do for you with Giatec’s SmartRock® Pro.