Giatec Delivers Most Innovative Generation of SmartRock Wireless Sensor to the Market

OTTAWA, Canada: Giatec, world leader in concrete testing technologies, has announced that the re-design of their award-winning flagship product, SmartRock, now available to pre-order, has been re-engineered with game-changing dual temperature monitoring capabilities for mass concrete applications.

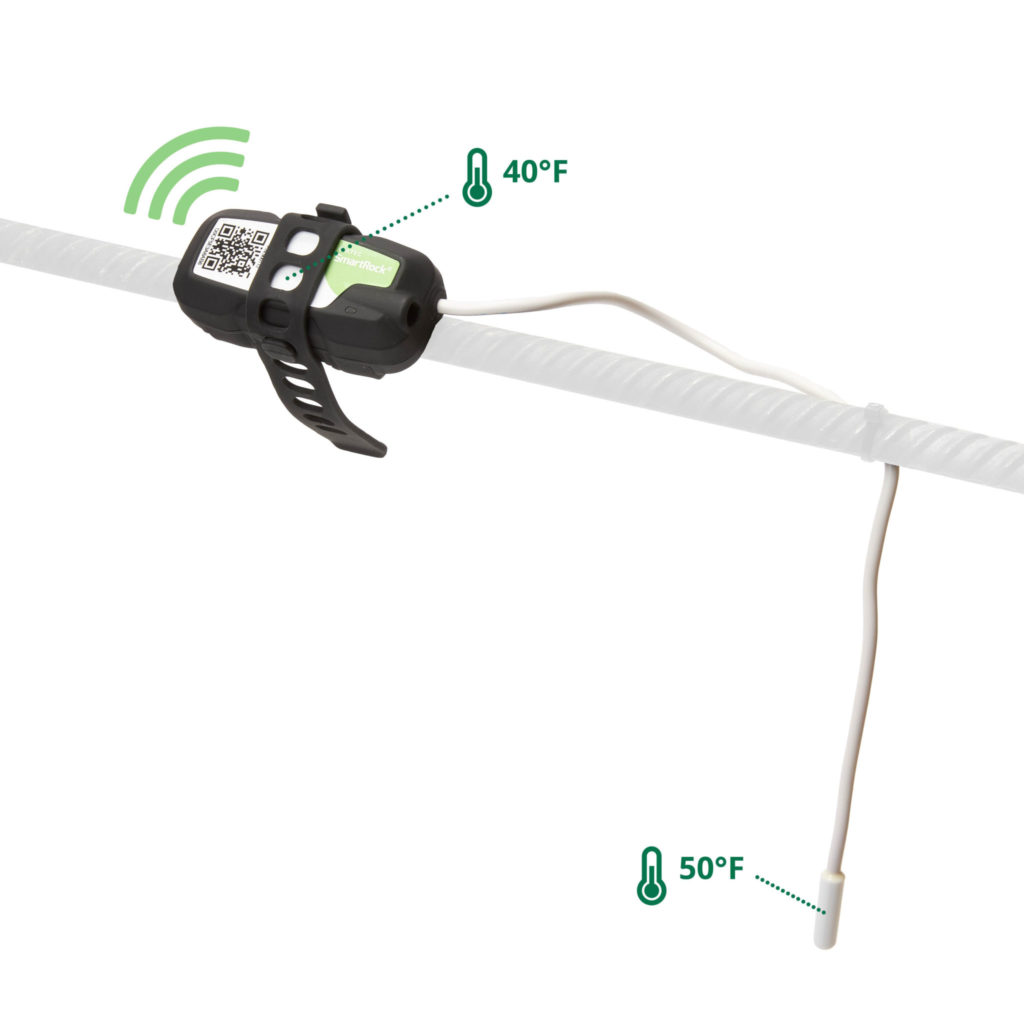

First announced in February of 2020 at World of Concrete, this latest generation of SmartRock takes concrete testing to a whole new level. In addition to an update in the sensor’s design, activation, installation, and wireless signal range, ‘SmartRock 3’ has been equipped with dual-temperature monitoring capabilities. This enables users to measure temperature values at two locations simultaneously. One temperature probe is located at the tip of the white temperature cable, another in the body of the sensor where the black transmitter is located. This function allows users to easily monitor temperature differentials between the concrete’s core and surface for mass pour applications.

“We are very happy with the new dual temperature functionality of the SmartRock 3 sensor. The temperature readings are very precise, helping us to accurately monitor temperature differentials of our mass pours at the surface and center of the slab, which can vary based on several factors. The sensors are also fast and straight forward to install, sending real-time data to our phones immediately.” says Walter Flood, Principal Engineer, Flood Testing Laboratories.

SmartRock is helping top construction companies eliminate concrete testing delays and take back control of their schedules in over 6,200 projects across 45 countries. As the first truly wireless sensor introduced to the market in 2015, SmartRock is the leading concrete maturity sensor for accurate monitoring of concrete curing and hardening. Unlike time-consuming and error-prone break tests, or cumbersome wired sensors, Giatec’s patented maturity sensor uses a highly accurate ASTM-approved testing method. Together with the Giatec 360™ platform and SmartHub™ remote monitoring device, this has enabled faster, safer, and more economical concrete construction.

ABOUT GIATEC

Giatec Scientific Inc. is a global company revolutionizing the construction industry by bringing smart testing technologies and real-time data collection to the forefront of every jobsite. Giatec’s suite of hardware & software products has leveraged advanced technologies such as; Artificial Intelligence (AI), and Internet of Things (IoT), including; wireless concrete sensors, mobile apps, and advanced non-destructive technologies (NDT) to drive innovation throughout concrete’s lifecycle. For more information visit www.giatec.ca.

MEDIA CONTACT

Dobrila Moogk, Vice President, Marketing

Tel: +1 (877) 497-6278 ext. 9280

marketing@giatec.ca

16 Responses

Does the atmosphere temperature impact the readings of the sensors? In India in some places the outside temperature varies between 40 degree C and 4 degree C.

Hello, thank you for your question and interest. As the sensors are designed to be fully embedded in the concrete they will be subjected to the concrete temperature and the readings will not be directly impacted. In fact, the sensors could help monitor the difference in temperature the environmental conditions may cause as concrete will typically be colder at the corners or edges of a structure where there is less mass effect and more exposition to the ambient temperature.

Hi Alicia

I am a Project Manager on the SKA project in South Africa. We are pouring mass reinforced concrete bases for out radio antennas. I think this could be a great asset in quality control. However, our site is extremely RFI sensitive. Can you give me more info on the device communication, e.g. frequency?

Hi Hendrik, thank you for your comment! If you submit a demo request using this form our sales and support team will be able to answer all of your questions. Here you are: https://www.giatecscientific.com/demo/

Would like to know more about concrete sensor to gauge strength of concrete through IoT application

Hi Prodyut, thank you for your comment. Please check out http://www.smartrock.com for more information on using our IoT-based technology, the SmartRock sensor, to monitor concrete temperature and strength.

Hi, do you have testing equipment to measure slump to eliminate the cone testing? What about the air testing?

Hi Pedro, unfortunately, this kind of equipment does not exist. The only accepted method that complies with ASTM standards is the cone testing for slump and the air meter for air testing. Hope this answers your question.

I have a cabinet full of smart rock 2’s. Are those now obsolete or will they continue to be supported?

Hi Chris, thank you for your comment, I bet other people are wondering the same. With thousands of customers with stock around the world, of course we would make sure you’re all taken care of. On the app just make sure to select SmartRock2 as your sensor and you’re good to go! And if you have any questions our support team is here to help at support@giatec.ca

What is data recording memory for each of the dual sensors?

Hi Alex, the SmartRock sensors record temperature and strength data for up to 4 months.

Can this product be used as a maturity meter to determine early compressive strength of concrete?

Hi Cliff, thank you for your comment, yes the SmartRock sensor can help you determine the compressive strength of early-age concrete. Read more on our SmartRock product page! https://www.giatecscientific.com/products/concrete-sensors/smartrock-maturity-meter/

price

Hi Jaesun, you can request a quote for pricing by filling out the request quote form at the bottom of our webpages, like this one https://www.giatecscientific.com/products/concrete-sensors/smartrock-maturity-meter/