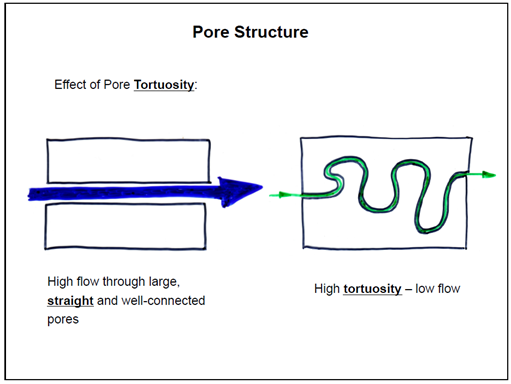

Concrete is a porous material which contains microscopic voids known as pores. These pores range in size, vary in connectivity (pore structure) and can be added to the concrete via air-entraining admixtures. The water-to-cementitious material and type of cementitious materials used have a significant effect on the pore structure. The connectivity of these pores and the way these pores are connected can be defined by the term: tortuosity: the twist and turns associated with the connectivity of pores. A visual representation of tortuosity can be found in Figure 1.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Figure 1: Effect of Pore Tortuosity

Inside these pores there is a conductive solution known as pore solution. This solution is highly saturated with alkali’s, namely Na+ and K+. Understanding the pore size, pore connectivity, and pore solution allows us to analyze the concrete’s ability to withstand the penetration of harmful agents such as chloride ions. These chloride ions can be introduced into the concrete during design in the form of chemical admixtures or they can be exposed to the concrete during its lifecycle through de-icing salts and atmospheric salinity (coastal environments). These properties can all fall under the mass transport phenomena.

If we can understand the transport properties of a specific concrete, in addition to other data, engineers can determine the service-life expectancy of a new structure or help estimate the remaining service-life of an existing one.

Standard Testing

What tests are out there to understand the permeability, and thus, durability, of concrete? Some tests include:

- Rapid Chloride Permeability (ASTM C1202): To assess chloride diffusivity

- Bulk Electrical Resistivity (ASTM C1760): Bulk electrical resistivity of concrete

- Absorption Test (ASTM C1585): To assess total porosity and fluid penetration

- Bulk Electrical Resistivity (ASTM C1876): Bulk resistivity of concrete

- Salt Ponding Test (ASTM C1556): To assess chloride diffusion coefficient

- Sulfate expansion test (ASTM C1012/C452): To assess durability when exposed to sulfate environments (e.g. sulfate-bearing soil)

- Alkali-aggregate reactivity tests (ASTM C1293/C1260): To assess expansion risk when using reactive siliceous aggregates

- Carbonation testing: Used when concrete is exposed to humidity and temperature conditions that can accelerate carbonation

- Freeze-thaw and de-icing salt scaling tests (ASTM C666): Used when concrete is exposed to freeze-thaw conditions

- Abrasion resistance (ASTM C944/C1138/C779): Used when concrete is exposed to conditions promoting abrasion

Bulk Electrical Resistivity of Concrete

Focusing on the resistance of concrete to harmful agents such as chloride ions, we’ll turn our eyes to Bulk Electrical Resistivity of Concrete (ASTM C1876 and CSA A23.2-26C). This method measures the bulk electrical resistivity of concrete, also known as the uniaxial method. An alternating current is applied to a concrete specimen and the voltage drop is measured. The resistance is calculated by dividing the measured voltage by the applied current, displayed with units Ohm or kohm. Resistivity is calculated by applying a geometry factor to the calculated resistance value. The results are displayed in ohm-m, ohm-cm, kohm-cm, kohm-m. Although resistivity is calculated by applying an appropriate geometry factor, resistivity is an intrinsic value of concrete and is independent of the specimen’s geometry. It is simply the resistance per unit of length of a material when subjected to an electrical field.

It is important to note the measurement device being used and the units of the displayed values. The device may display resistance, impedance, resistivity, or apparent resistivity. The apparent resistivity can be defined as the resistivity of a specimen without including the appropriate geometry factor.

This apparent resistivity can be found by conducting the popular surface resistivity measurement under AASHTO T358. This test method applies a geometry factor assuming that the specimen under consideration is semi-infinite. The issue is that the concrete cylinders tested are not semi-infinite in length. Therefore, an additional geometry factor must be applied based on the probe spacing of the Wenner-Array setup and size of the concrete sample. It is understood that for a 4 x 8 inch cylinder, the apparent resistivity will be approximately double that of the bulk resistivity measurement performed on the same specimen. This is why it is crucial to note the measurement used, the units of the displayed values and the correction factors that are applied or not applied. Correctly interpreting these results is very important as the introduction of performance-based specifications for mixtures is increasing in popularity.

Understanding the Formation Factor

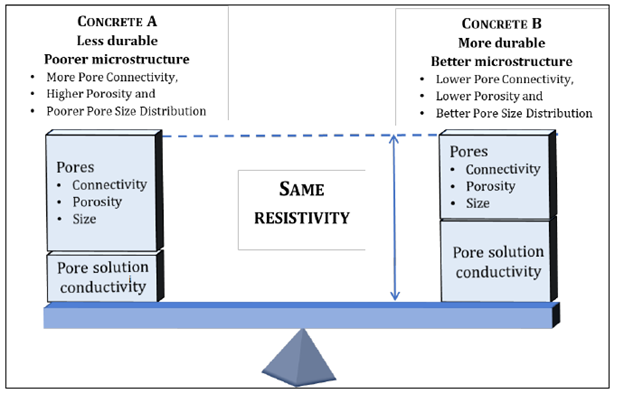

The formation factor is the ratio of concrete resistivity to the resistivity of its pore solution. Remember, pore solution influences the electrical resistivity of a specimen. Although, electrical resistivity allows us to understand important properties of the concrete’s microstructure, and thus, durability, every method has its limitations. One limitation of concrete’s electrical resistivity measurement for durability is the resistivity or conductivity of the pore solution. This can be illustrated in Figure 2.

Figure 2: Pore Solution Conductivity

Figure 2 depicts the effect of pore solution conductivity on the outputted resistivity results where durability claims are partially or fully derived. A concrete sample can have a poor microstructure (less durable) but output similar resistivity results based on the conductivity of its pore solution.

Therefore, normalizing the electrical resistivity of a specimen to its pore solution resistivity, allows us to further understand the total pore volume and how these pores are interconnected. The formation factor has a direct relation to concrete’s bulk diffusion coefficient. Further, the formation factor can be used for lifecycle analysis modelling.

Lastly, the accurate calculation of the formation factor is critical to understanding concrete’s durability. As mentioned, the formation factor is a function of concrete resistivity and pore solution resistivity and there are a few methods to calculate or estimate the pore solution resistivity. In addition, using the correct device to measure concrete resistivity is vital.