Every concrete professional aims to perform critical operations faster and with the highest possible quality. Remote monitoring systems such as the SmartHub™ Long Range developed by Giatec are valuable tools for this need. Following the first part of the long-range series, this blog will delve into the applications of the SmartRock® Long Range.

Learn the ins and outs of mass concrete pours

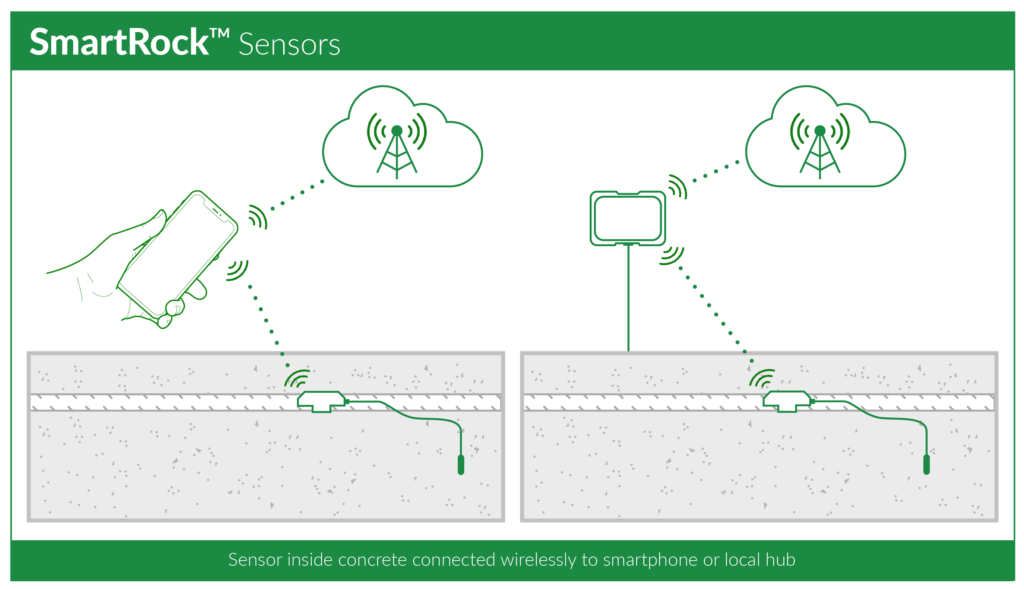

Fully Embedded Wireless Systems

The proliferation of wireless sensory technology has been incredibly helpful in harnessing vital information from structural elements in the last couple of decades. A lot of construction projects are taking advantage of this technology and have fully embraced embedded solutions. This is because they are reliable and easy to use, giving real-time data of the in-place element. Due to this added value, some project specifications will specifically require the use of fully embedded and wireless systems.

However, despite technological advances, there are certain jobsite characteristics where the range of data transmissibility with standard solutions could be a challenge. Also, there could be a demand for real-time monitoring of concrete conditions, which requires constant data acquisition from the sensors installed. Remote project locations and on-site structural elements with limited accessibility of human personnel could hinder the frequent acquisition of data. In turn, this presents some limitations to the real-time monitoring experience in the field.

In all these instances, the long-range system would leverage data acquisition where mobile phones would not be the ideal solution. As explained in the first part of this series, both the SmartHub Long Range and the SmartRock Long Range are meant to be used together. Thus, we can examine some of the applications where their use is the most desirable:

- Cold Weather Concreting

- Highway Structures

- High-rise Buildings

Cold Weather Concreting

In low-temperature regions, construction activities tend to reduce during winter seasons due to harsh weather conditions. Contractors must be extra careful when placing concrete so they can satisfy quality control requirements. In some cases, this is when real-time data is necessary. Having field personnel collect sensor data during winter is not always a sustainable procedure, especially if the elements are long distances apart. Therefore, remotely having real-time insights about the condition of concrete for quality assurance is a game changer.

Highway Structures

Concrete structures such as tunnels and bridges are built to connect cities. Sometimes, they are in remote locations where there is little LTE infrastructure. This makes real-time monitoring of concrete structural elements a challenging task. Additionally, bridge piers and columns are structures often spaced at significant distances apart, adding more work for sensor data collection. Instead of having site personnel dedicated to performing this role of real-time data collection, the long-range system could be used to retrieve sensor data from the concrete elements. Additionally, DOTs, MTO and other transportation agencies across the globe require real-time data monitoring for quicker decision-making. This is necessary for opening roads and timesaving.

High-rise Buildings

As urban areas become denser and more populated, high-rise buildings become more common and useful. In these construction projects, real-time monitoring is essential for various reasons such as post-tensioning and formwork removal. The SmartHub Long Range allows customers to place the gateway on the ground level and connect with the SmartRock Long Range sensors up to the 10th level. This allows for real-time monitoring of temperature and strength of the in-place element without going up and down the floors. Furthermore, the long-range real-time monitoring system allows customers to stress cables quickly, reducing time on the project schedule.

SmartRock Long Range Sensors for Remote Monitoring on Jobsites

In addition, construction companies that want to incorporate their raw data into their in-house IT infrastructure can seamlessly do so by integrating with Giatec 360™. This is possible through our API and Procore Integration. With the Giatec 360 dashboards, customers have access to the SmartRock App features and much more, providing valuable insights to make fast and efficient decisions on all construction projects.

Overall, monitoring the concrete temperature and strength through embedded sensors is now a much more common standard. Yet, the addition of long-range sensors and Gateways is a step further into the future. These systems enable contractors, testing agencies, and concrete producers to have real-time insights into entire projects with just the click of a button.