Concrete is the backbone of modern construction, from the foundations of skyscrapers to simple residential sidewalks. Its adaptability is largely due to formwork, also known as shuttering, a system of molds or structures that hold the concrete in place while it hardens. This crucial stage of the building process ensures the concrete retains its desired shape, strength, and finish. In this post, we will explore different types of formwork, innovations in the field, and practical tips for selecting and using formwork efficiently in various construction projects.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

What is Formwork?

Formwork refers to temporary or permanent molds into which concrete is poured. Without formwork, the liquid concrete would not stay in place long enough to solidify into its intended structure. More than just a mold, formwork plays a vital role in the structural integrity, shape, and finish of the concrete. A well-designed formwork ensures the safety of workers, prevents collapse, and enhances the final quality of the concrete surface.

Prove you concrete better with the SmartRock® Prove-It Kit.

Importance of Formwork in Construction

Formwork serves multiple functions in a construction project:

- Defines Shape: It molds the concrete into a specific shape, whether it is for a complex architectural feature or a straightforward wall.

- Supports Concrete: It supports the weight of the wet concrete until it hardens and gains enough strength to support itself.

- Surface Finish: The type and quality of formwork influence the final texture and finish of the hardened concrete.

- Ensures Safety: Properly constructed formwork prevents collapse or structural failure, ensuring a safer construction environment.

Various Types of Formwork

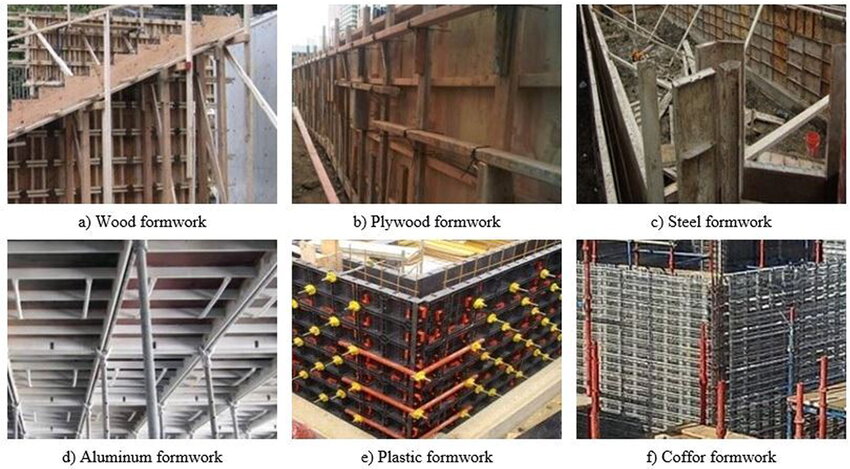

Formwork can be made from a variety of materials, each chosen based on the specific needs of the project. The type of formwork selected will influence the cost, labor, and the final appearance of the concrete. Below are some of the most commonly used types of formwork, along with their advantages and disadvantages.

| Type of Formwork | Overview | Advantages | Disadvantages |

|---|---|---|---|

| Timber Formwork | Oldest and most versatile, made from wood planks. Ideal for smaller projects. | – Adaptable to complex shapes.

– Cost-effective for small jobs. – Easy to produce and remove. |

– Short lifespan; susceptible to warping and rotting.

– Labor-intensive to install. – Not suitable for large repetitive projects. |

| Steel Formwork | Durable, reusable, made from steel panels. Ideal for large projects. |

– Long lifespan with hundreds of reuses.

– Provides smooth, high-quality surfaces. – Strong and handles heavy loads. |

– High initial cost.

– Requires lifting equipment. – Less flexible for custom shapes. |

| Aluminum Formwork | Lightweight, faster alternative to steel. Ideal for efficient projects. |

– Lightweight and easy to handle.

– Quick assembly and disassembly. – Durable with long lifespan. |

– Higher cost than timber.

– Can react with wet concrete if untreated. – Less sturdy than steel under heavy loads. |

| Plastic Formwork | Lightweight and reusable, ideal for repetitive structures. | – Moisture-resistant and easy to handle.

– Reusable multiple times. – Lightweight for easy transport. |

– Limited load-bearing capacity.

– Not suitable for large-scale projects. – Can be more expensive than timber for small jobs. |

| Plywood Formwork | Often combined with timber; smooth surface finish. |

– Flexible and can be shaped easily.

– Provides smooth finishes. – Inexpensive and accessible. |

– Limited reusability.

– Susceptible to water damage. – Requires careful handling to avoid damage. |

Image courtesy of Application of multi-criteria analysis in the selection of formwork material for high-rise building construction projects

How to Choose the Right Formwork for Your Job

Choosing the right formwork for your project is a critical decision that will affect the efficiency, cost, and quality of the final product. Here are some factors to consider:

- Project Scale and Complexity

For large-scale, repetitive projects like high-rise buildings or bridges, steel or aluminum formwork is often the best option due to its durability and reusability. These materials can withstand heavy loads and be reused hundreds of times, making them cost-effective in the long run. For smaller or more complex projects, such as custom residential designs or one-off structures, timber or plywood formwork may be preferable. These materials are more flexible, easier to modify on-site, and cost less upfront.

- Budget

If you are working with a limited budget, timber or plywood formwork can be an affordable solution, especially for smaller jobs. However, if the project involves multiple uses or long-term applications, investing in more durable materials like steel or plastic can result in long-term savings, even though the initial costs are higher.

- Surface Finish Requirements

If the appearance of the concrete surface is a major consideration, you’ll need to choose a formwork material that provides a smooth, high-quality finish. Plywood and steel are commonly used for projects where the final surface finish is important, as they can create smooth surfaces with minimal imperfections.

- Reusability and Lifespan

For projects where formwork needs to be reused multiple times, steel or aluminum formwork is ideal because of their long lifespans and resistance to wear and tear. If the project is a one-time build or only requires minimal reusability, timber or plywood formwork may suffice.

- Speed and Ease of Installation

On fast-paced projects, it’s essential to choose formwork that can be quickly assembled and disassembled. Aluminum and plastic formwork tend to be lighter and easier to work with than steel, requiring less manpower and equipment for setup. Modular systems can also save time on-site.

Formwork in Different Construction Methods

Formwork requirements vary depending on whether the concrete is precast or cast-in-place.

i. Precast Concrete

Precast concrete elements are produced in controlled factory environments, then transported to the construction site for installation.

Formwork Needs:

- High-precision molds to ensure uniformity across multiple pieces.

- Durable materials like steel or fiberglass to withstand repeated use.

- High-quality finishes to reduce the need for on-site finishing.

ii. Cast-in-Place Concrete

Also known as in-situ concrete, cast-in-place concrete is poured into molds at the construction site.

Formwork Needs:

- Flexible and easy-to-assemble materials like timber or plywood.

- Cost-effective, as formwork is usually discarded after use.

- Quick setup and removal to keep the project on schedule.

- Learn more about Cast in Place Concrete in this blog – Back-to-Basics: All About Cast-in-Place Concrete blog

The difference between precast and cast-in-place concrete

Sliding Formwork: Efficient and Continuous Construction

Sliding formwork, also known as slipform, is a construction technique used for tall structures like chimneys, towers, and silos. In this method, the formwork is continuously raised vertically while the concrete is poured in a continuous, unbroken process. The formwork “slides” up as the concrete below hardens, allowing for continuous construction without the need for stopping or dismantling the form.

Advantages of Sliding Formwork:

- Continuous Pouring: The ability to continuously pour concrete speeds up the construction process, especially for tall vertical structures.

- Labor Efficiency: Sliding formwork reduces the need for frequent formwork disassembly and reassembly, minimizing labor costs.

- Uniform Surface Finish: Since the process is continuous, it results in a smooth and uniform surface finish without joints or seams.

Sliding formwork is commonly used for projects where a high degree of vertical precision is required. It can be highly efficient for constructing tall cylindrical structures, reducing the need for multiple formwork setups.

Sliding formwork can be used in many different applications

Essential Components of a Formwork System

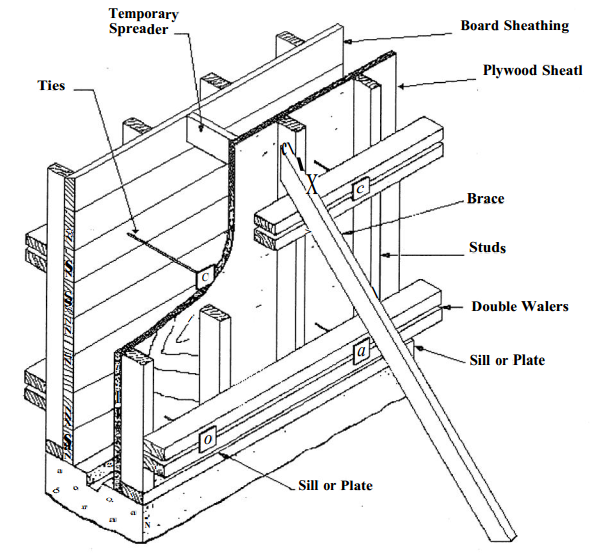

A complete formwork system is made up of several components, each designed to maintain the shape of the mold and handle the forces exerted by the wet concrete:

- Sheathing: The surface material that comes in direct contact with the concrete (often plywood, steel, or aluminum).

- Joists: Horizontal beams that support the sheathing and distribute the load.

- Bearers (Stringers): Larger beams beneath the joists that transfer loads to the ground or supports.

- Ties: Prevent the formwork from spreading under the pressure of the concrete.

- Bracing: Vertical or diagonal supports that keep the formwork stable during the pouring process.

- Supports/Props: Vertical posts that carry the load from the formwork to the ground or scaffold.

Image courtesy of Civil Engineering Forum, Team Civil

Formwork Standards and Safety

Several key standards regulate the design, construction, and use of formwork to ensure safety and structural integrity:

- ACI 347-04: This American standard outlines requirements for formwork design, construction, and removal, focusing on safety and allowable deflection limits.

- CSA A23.3: The Canadian equivalent, which also includes provisions for reusing formwork without compromising structural integrity.

- EN 13670: The European standard governing concrete formwork, ensuring safety and load-bearing capacities during the construction process.

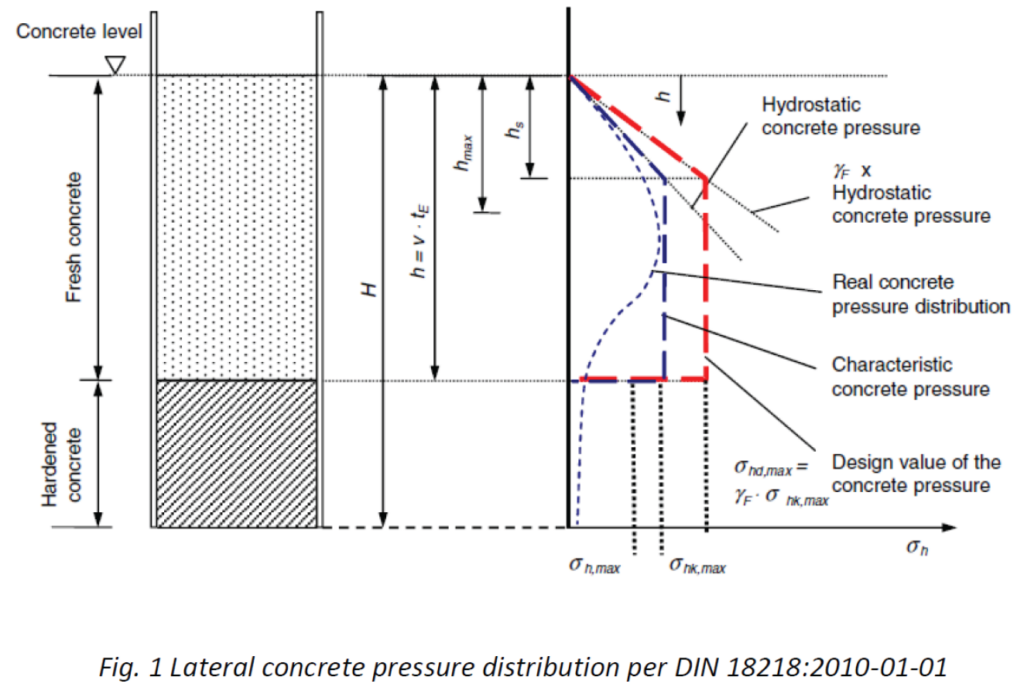

Image courtesy of Kern.

Economic Considerations of Formwork

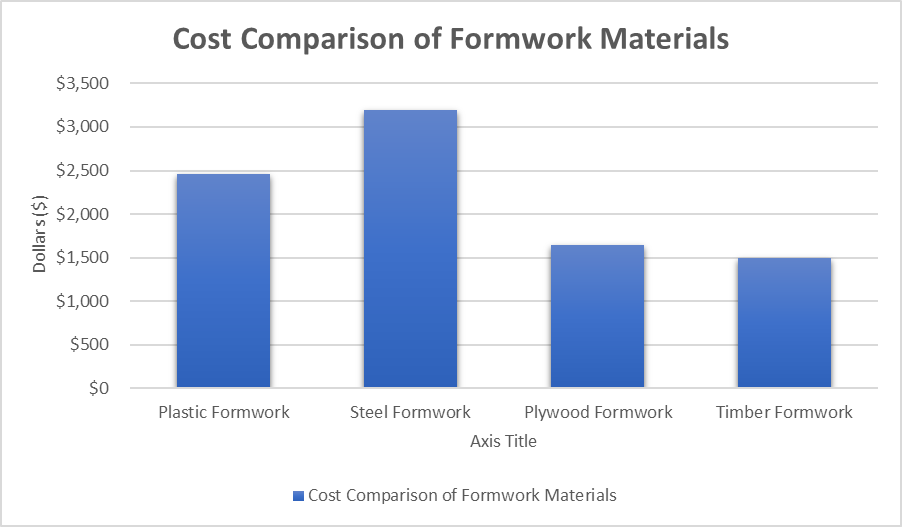

Formwork can account for up to 50% of a project’s total concrete costs, making it a critical factor in budgeting. Key considerations include:

- Material Costs: Steel and aluminum have higher upfront costs but offer long-term savings through reusability.

- Labor Costs: Easy-to-handle materials like plastic and aluminum can reduce labor costs due to faster assembly and disassembly.

- Lifespan: Timber formwork typically lasts for 3-5 uses, whereas steel can be reused hundreds of times, making it more economical for large projects.

Data referenced from Life cycle assessment and economic analysis of Reusable formwork materials considering the circular economy

Top 5 Global Formwork Manufacturers

The global formwork market is led by several key players known for their innovation, quality, and extensive product offerings. The top five formwork manufacturers are PERI, Doka, MEVA, ULMA, and Alsina.

- PERI is renowned for its high-quality modular systems and has a strong focus on sustainability, with a wide range of reusable formwork solutions.

- Doka, another global leader, is celebrated for its innovative technologies and comprehensive timber, steel, and aluminum systems, though its complex assembly can be a challenge.

- MEVA offers advanced safety features and durable plastic and aluminum formwork systems, making it a strong choice for projects with demanding safety requirements.

- ULMA specializes in robust systems for high-rise structures, with a focus on energy-efficient production methods, although it’s less geared toward smaller projects.

- Lastly, Alsina provides lightweight and modular designs, excelling in reusable systems, though it has limited advanced technologies compared to other top players.

These manufacturers drive the industry forward with solutions that prioritize efficiency, safety, and sustainability.

Innovations in Concrete Formwork

The formwork industry continues to evolve with new technologies and materials aimed at improving efficiency, safety, and sustainability. Here are a few key innovations:

3D-Printed Formwork

3D-printed formwork is an emerging technology that allows for the creation of highly intricate molds directly from digital designs. This method enables architects to design complex structures that would be difficult or expensive to achieve with traditional formwork methods. The technology also minimizes material waste, as the printing process only uses materials where needed.

Self-Sensing Formwork

Self-sensing formwork integrates advanced sensors that monitor the concrete’s curing process in real-time. These sensors provide immediate feedback on factors like structural loads and concrete strength, allowing for optimized formwork removal schedules.

Image courtesy of Doka

Sustainable Formwork Materials

Learn more methods being used in the industry for sustainable construction practices here!

With an increased focus on sustainability, new formwork materials are being developed from eco-friendly, recyclable, or biodegradable resources, such as recycled plastics or bamboo. These materials help reduce the carbon footprint of construction projects.

_______

Formwork plays a crucial role in ensuring the success of any concrete project, from small residential builds to large-scale infrastructure developments. Understanding the different types of formwork, their specific applications, and the technical standards governing them is essential for achieving quality and safety.

With ongoing innovations like 3D-printed formwork and self-sensing technologies, the future of concrete formwork is promising. Construction professionals can deliver high-quality, efficient, and sustainable results by staying informed about these advancements and choosing the right formwork for each job.

Now that you’re an expert in all types of formwork, learn about formwork removal next in our Essential Guide to Concrete Formwork Removal and Cycling Benefits.