Giatec continues to uphold the value of bridging the gap between academic research and sustainable construction on the jobsite. Every year, we recognize civil engineering students, researchers and faculty across Canada and the U.S. with the Giatec Best Paper Award for Sustainability in Construction. Below is a summary of the winning 2024 paper submitted by Dr. Kai Gong and Dr. Claire E. White, “Development of Physics-based Compositional Parameters for Predicting the Reactivity of Amorphous Aluminosilicates in Alkaline Environments.” Learn more about how to join the list of winners and showcase your innovative research for the Best Paper Award 2025!

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Research Background

Portland cement (PC) and concrete have been instrumental in shaping modern civilization, driving unprecedented progress in infrastructure and construction. However, use of concrete has significant environmental consequences, with PC production alone contributing approximately 8% of global anthropogenic CO2 emissions. As global cement demand is projected to grow by 20–30% over the next three decades, reducing its carbon footprint is crucial to achieving carbon neutrality and combating climate change—a challenge fundamental to humanity’s resilience and survival. Blended cements and alkali-activated materials (AAMs) are two important classes of low-CO2 cement binders, which have been extensively explored in academia and industry. These alternatives utilize industrial byproducts with significantly lower CO2 emissions, such as slags and fly ash, either as supplementary cementitious materials (SCMs) or precursors. Beyond lowering CO2 emissions, they promote waste recycling, mitigating costly disposal and environmental concerns.

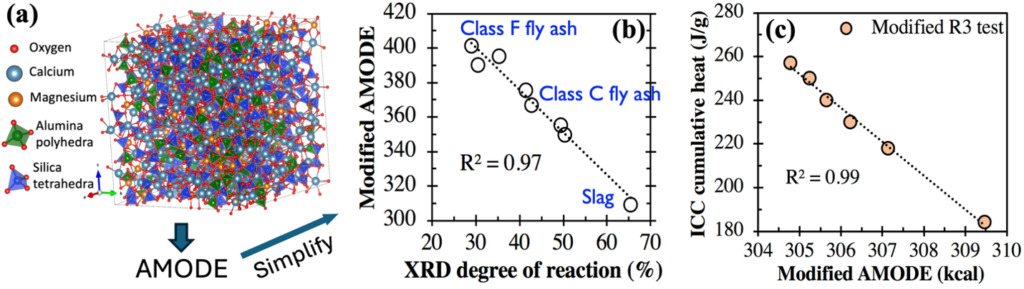

A major challenge in utilizing these byproducts—especially for AAMs made from 100% waste materials—is their inherent variability in reactivity depending on their sources. This variability makes it difficult to formulate reliable designs and limit the predictability of the engineering performance of final products, posing a significant barrier to broader adoption in construction. Addressing this challenge necessitates establishing the important relationships between the composition, structure, and reactivity of these materials. To this end, Dr. Kai Gong, in collaboration with Dr. Claire White, leveraged atomistic simulations to obtain detailed structural representations for various amorphous aluminosilicates (an example given in Fig. 1a) [1-2]—the primary reactive components in these industrial byproducts. Building upon the resulting structural attributes or descriptors, this study [3] aimed to derive physics-based compositional parameters for the rapid and accurate prediction of the relative reactivity of amorphous aluminosilicates.

Important Findings

In this investigation [3], several physics-based compositional parameters were derived for rapid evaluation of the relative reactivity of CaO-Al2O3-SiO2 and CaO-MgO-Al2O3-SiO2 glasses in alkaline environments, including the modified average metal oxide dissociation energy (AMODE) parameter. Due to the incorporation of structural information, these parameters are seen to outperform existing compositional parameters reported in the literature across a wide range of amorphous aluminosilicate glasses (Fig. 1b). Analysis of literature data for six blast-furnace slags revealed that the modified AMODE parameter is inversely correlated with the heat of hydration measured using a modified R3 test (Fig. 1c, data from ref. [5])—the state-of-art experimental method used in the cement and concrete community for assessing the reactivity of SCMs and their suitability for blended cement production. While experimental methods typically require at least 24 hours and specialized equipment, the modified AMODE parameter can be calculated in a minute using chemical composition data routinely measured in industrial workflows.

The modified AMODE parameter shows great potential as a rapid pre-screening tool for SCM or precursor reactivity, offering substantial potential for economic and time savings. By quickly identifying less promising SCMs or precursors, it enables researchers to focus experimental validation on more viable candidates, thereby reducing the need for costly and labor-intensive reactivity testing across all materials. Lastly, the limitations of the proposed compositional parameters have been thoroughly discussed in this study, highlighting areas for future research and potential refinements to further enhance their applicability.

Reference

[2] Gong, K., & White, C. E. (2021). Cement and Concrete Research, 150, 106588.

[3] Gong, K., & White, C. E. (2023). Cement and Concrete Research, 174, 107296.

Want to know when entries open up again? Stay in the know! Join our mailing list.

Authors Dr. Kai Gong from Rice University and Dr. Claire E. White from Princeton University. Read the full article.

Dr. Kai Gong is an Assistant Professor of Civil and Environmental Engineering at Rice University. He can be contacted at kg51@rice.edu.