The Project

Located in the heart of Kirkland, Quebec, the Pandora Self Storage Kirkland facility is a modern, multi-level structure designed to meet the rising demand for secure and climate-controlled storage solutions in the Greater Montreal area. Developed by Broccolini, construction began in May 2024 on a 2.17-acre site just off Highway 40, offering exceptional visibility and easy access.

The facility will feature four above-ground stories, a basement level, and over 1,000 individual storage lockers. In addition to advanced digital access and high-level security systems, Pandora will offer co-working spaces, redefining the user experience in the self-storage industry. Once completed, the building aims to bring elevated service and reliability to the sector.

How to Build Smarter, Not Slower

For Broccolini, the Pandora Kirkland project presented a unique opportunity—not just to build a new self-storage facility, but to test innovative technology that could enhance their efficiency on future builds. With multiple concrete slab pours and a full four-story structure to complete, the team saw the potential for optimization.

Broccolini is no stranger to the familiar challenges within the concrete industry, such as how to avoid delays caused by traditional concrete strength testing methods and when to perform critical operations like removing formwork.

Typically, Broccolini relied on concrete cylinders and pull-out tests to track strength gain, which is a process that can slow down construction progress by several days as teams wait for lab results. On a project with multiple slab pours and a tight timeline, this meant that every day mattered.

After previously hearing about SmartRock® and its features checking off every box, Broccolini’s operations team decided to test pilot Giatec’s leading wireless concrete sensors.

Seamless SmartRock Setup, Minimal Learning Curve

From the very beginning, Broccolini found the adoption of SmartRock to be quick, intuitive, and well-supported. The Engineering Solutions team helped calibrate the sensors at the concrete plant and provided annotated site plans with sensor placements for each pour. “Putting the locations on the plans and just making the process of calibration seamless really made for a positive experience,” says Bryce Thomassin, Project Manager at Broccolini.

SmartRock’s calibration process made onboarding a breeze. After just a few brief training sessions, the team was ready to monitor pours independently.

The Project Coordinator handled installation using the SmartRock app, embedding sensors directly on the rebar before each pour. With minimal training and zero disruption, the team was able to integrate SmartRock into their workflow with confidence and streamline their operations.

Confidence in Every Pour

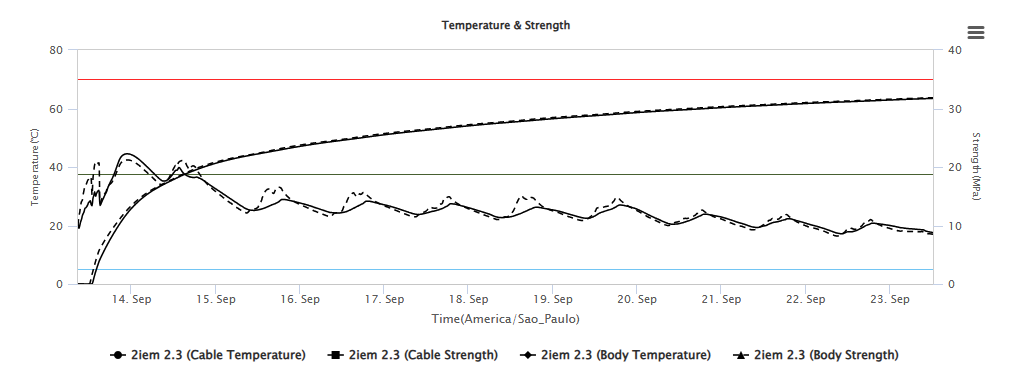

The sensors transmitted data every 15 minutes to ensure the concrete was hitting strength targets per CSA A23.1 standards. This helped Broccolini eliminate the lag associated with lab testing and provided real-time visibility into critical project milestones. By knowing when to safely remove formwork and shoring in real-time, the team could confidently transition to subsequent construction phases as soon as possible.

With SmartRock’s accurate, real-time concrete strength data available directly on mobile devices, the project team was able to shave two weeks off of their project schedule! This translated to approximately $30,000 in cost savings on the project—achieved through faster turnaround, site resources, and reduced general labor requirements.

In order to be able to remove formwork quicker on the project by knowing those live results of the concrete itself, it’s neat to use it for the first time on this project! [I]t really helped us out because ultimately, it saved two weeks on the project schedule, which leads to cost savings.

Bryce Thomassin, Project Manager, Broccolini

Trial Run. Real Returns.

The Pandora Self Storage Kirkland project served as a successful pilot for Broccolini’s broader implementation of SmartRock technology. By shifting away from traditional break tests and embracing remote monitoring, the team gained schedule flexibility and confidence in the integrity and performance of their concrete.

SmartRock helped Broccolini optimize labor usage, reduce schedule risk, and streamline decision-making—all while maintaining compliance with third-party testing and CSA standards.

Broccolini has since rolled out SmartRock Long Range sensors on another project, citing its added benefit of extended wireless range to gather real-time strength data—giving back more time to complete other essential job site tasks.

With SmartRock, Broccolini is leading the way in smarter construction by further enhancing on-site efficiency.