Field-Cured vs. Standard-Cured Cylinders: How They Affect Concrete Performance

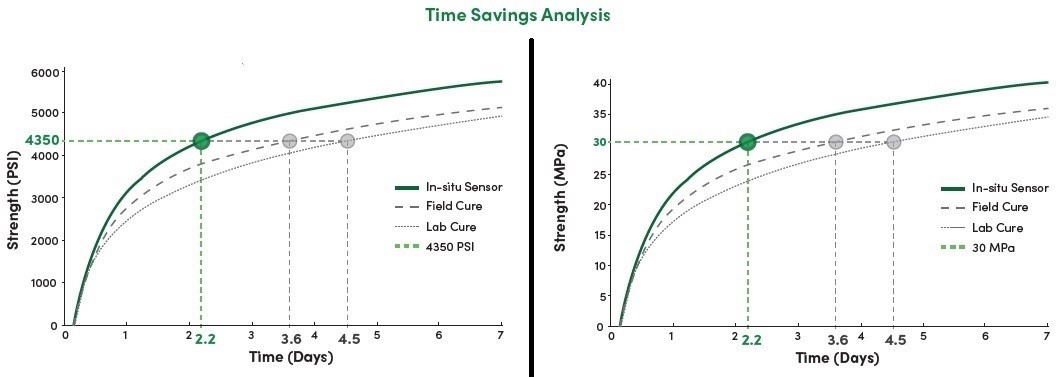

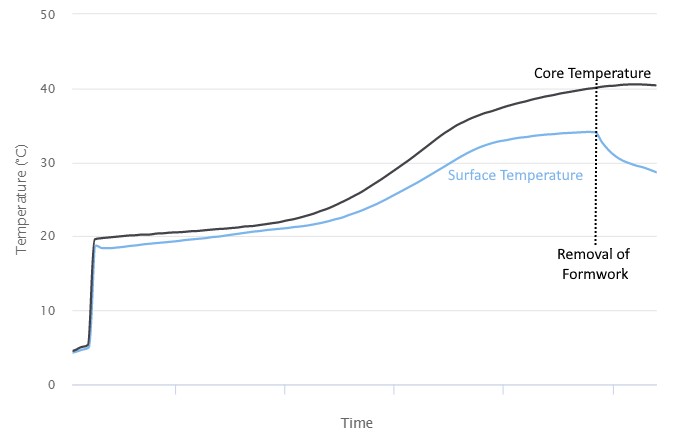

How do Curing Methods Affect Concrete Field Performance? ASTM C31 is the standard that defines two different concrete curing conditions, standard curing and field curing. This standard dictates the procedures for making and curing test cylinders. At the same time, it can become a problem when an engineer…