Modernizing a Legacy

Founded in 1968, Trio Ready-Mix has provided ready-mix concrete services and materials to Southern Vancouver Island for over 50 years. Acquired by Ralmax Group in 2013, Trio has since undergone a remarkable transformation. This transformation is driven by a commitment to continuous improvement, innovation, and investment in their concrete operations. With two new plants and the adoption of technology to enhance quality and sustainability, the need for better data consolidation grew. More specifically, Stephen Hay, General Manager, required tools to enable the next generation of technical service leaders, allowing him to spend more time on the business rather than in it.

Navigating Data Fragmentation and System Limitations

Before implementing SmartMix™, Trio Ready-Mix managed their high-volume mixes manually, requiring significant time and expertise to maintain. As a one-plant operation, Trio handled extensive data across legacy systems, but the lack of interoperability created synchronization challenges. The time required to amalgamate and analyze data limited their ability to make real-time, proactive decisions. With their anticipated growth, Stephen Hay sought a system that not only consolidated data but also provided high-level analysis. This would enable him to dedicate more time to business expansion and delegation. While their existing approach was effective, the company needed a more agile system to quickly adapt to market changes.

SmartMix Streamlines Concrete Operations

To address these needs, Trio Ready-Mix decided to invest in SmartMix—a comprehensive mix management system designed to streamline concrete operations, increase profitability, and enhance decision-making. Initially cautious, Trio recognized the system’s potential to revolutionize their approach to concrete operations. As Stephen Hay, General Manager, emphasized, “Something that would take us at least 20 minutes to do, SmartMix can do in the tenth of a second.” This allowed Trio to shift from reactive to proactive management, leveraging real-time data analytics to optimize mixes and identify savings.

With SmartMix, I finally have a system that not only stores data but also analyzes it at a high level and produces reports to meet CSA requirements.”

Stephen Hay, General Manager, Trio Ready-Mix

Proactive Quality Control & Peace of Mind

The integration of SmartMix resulted in significant improvements across Trio Ready-Mix’s concrete operations. Within a short timeframe, Trio achieved notable reductions in material usage. As a result, they were able to cut cement by 50kg per batch—a feat previously challenging to achieve manually. Initially, as a one-plant operation, Trio Ready-Mix was generally well-tuned with their high-volume mixes. However, they found that the general Roxi model required a period of adaptation to provide immediate value. As Roxi continued to learn and refine her insights, it took only two months for Trio to start seeing tangible benefits. During this time, Trio chose a conservative approach for their first adjustment, then revisited the process, collected more data, and opted for a more aggressive adjustment. This incremental aspect of SmartMix allowed them to push their optimization boundaries further.

Moreover, SmartMix enabled Trio to mitigate operational risks and uncertainties. Stephen Hay, General Manager, noted, “With SmartMix, we were able to take out some of the risk and sleepless nights from the equation, making our operations more reliable and efficient.” This enhanced operational reliability not only bolstered Trio’s competitive position but also fostered a culture of continuous improvement and innovation within the organization.

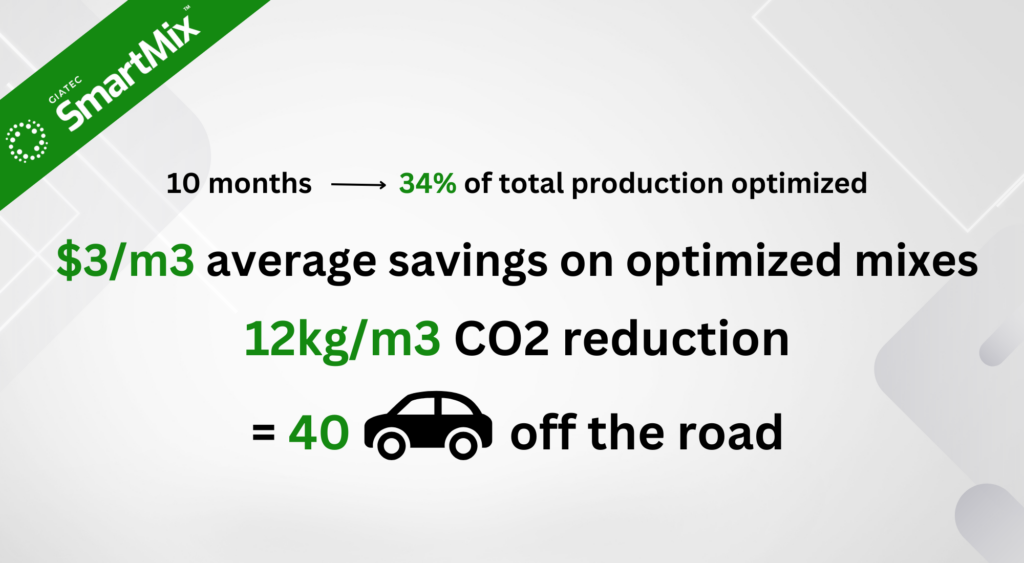

Within their 10th month of usage, Trio Ready-Mix has seen optimizations across 34% of their overall production. With an average of $3/cubic meter reduction across their optimized mixes, this equated to 40 cars a year in CO2 emissions that have been “taken off the road.” As SmartMix provides optimizations in the form of incremental adjustments, this is only the beginning for Trio Ready-Mix.

Insights from a Leading Concrete Producer

Looking ahead, Trio Ready-Mix is committed to maximizing the full potential of SmartMix for sustained growth and operational excellence. They are increasingly confident in the system’s suggestions and eager to explore more granular adjustments to further optimize their mix designs. As Trio expands and takes on new acquisitions, SmartMix remains integral to their strategy for achieving operational excellence and meeting the evolving demands of the concrete market. Their newly acquired company’s Quality Control team, immediately asked, “When can we get this?” upon seeing the capabilities of SmartMix. Stephen Hay emphasizes the importance of leveraging available data to optimize and mitigate risks in operations, pointing out that many companies miss opportunities by not utilizing their data efficiently. With SmartMix, Stephen looks forward to the ease of organization and the ability to monitor everything in one central location.