The Project

NEOM is a special economic and technological city promoted by Saudi Arabia in the northwest of the country, designed to attract foreign investment and create free market space. As part of this colossal infrastructure development initiative, the joint venture between FCC Construction, China State Construction, and Shibh Al-Jazira was appointed to execute the drill and blast tunneling projects. With its vast experience on large-scale projects, FCC Construction has built more than 700 kilometers of tunnel lead, as well as various types of roads, rail, metropolitan, and water supply projects with a high degree of technical and field difficulty. For the NEOM giga-project, the focus is the construction of tunnels spanning over 28 kilometers to accommodate both high-speed and freight rail services. These are meant to improve the efficiency and safety of transportation within the region.

Finding the Best Monitoring Technology for Concrete Strength

Before introducing any advanced technology, the consortium relied on standard lab-cured samples and cylinders for assessing concrete strength, which posed a major challenge as they could not efficiently track compressive strength. The readings obtained through lab samples often resulted in delays in the decision-making process. During the exploration of new construction technologies to optimize the efficiency and accuracy of concrete strength monitoring, the team discovered SmartRock®, the award-winning wireless concrete sensor.

SmartRock Lets You Take Control From the Very Beginning!

The primary goal of implementing SmartRock in the NEOM project was to monitor concrete’s temperature differentials, maturity, and compressive strength during the first day of the curing phase. Given the large scale of this tunneling concrete project and the need to facilitate timely decision-making, SmartRock was a useful tool in providing real-time insights. With the constant influx of data from the sensors, the consortium team had instant control and accurate information on the concrete’s strength from the onset of curing.

By leveraging the real-time insights provided by SmartRock on the NEOM tunneling project, we have transformed our approach to concrete strength monitoring. We work faster and more efficiently.”

Emrah Ozturk, Deputy QA/QC Manager.

The Team Shortens Timelines with SmartRock!

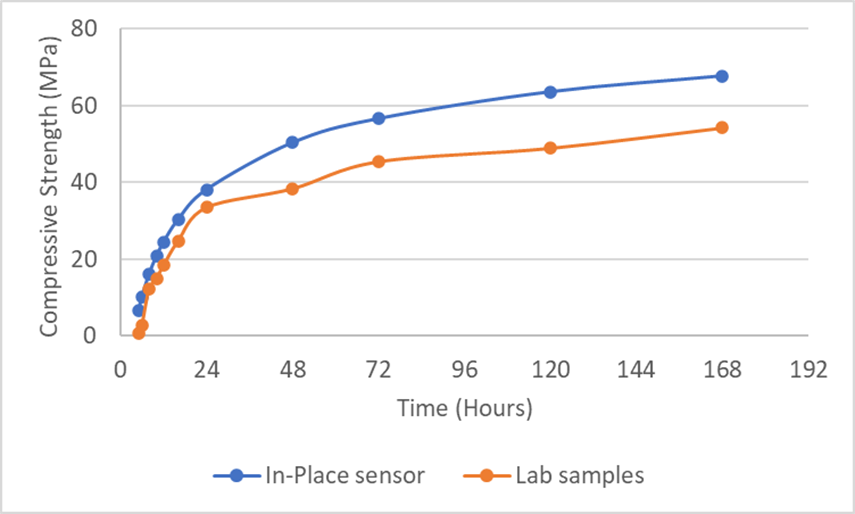

With SmartRock, the tunneling team observed significant improvements in the efficiency of concrete formwork removal. Since the sensors calculate strength using the maturity method, it was easy to know precisely when the right strength was achieved, hence speeding the formwork removal time. Apart from formwork removal, the data that SmartRock collected allowed the team to know that their concrete was increasing its strength at a faster rate compared to the information they received from standard lab-cured samples, as seen in Figure 1. With this valuable information, the consortium improved resource utilization and saved costs by shortening their work timelines.

In short, the advanced capabilities for concrete monitoring offered by SmartRock played a pivotal role in optimizing the efficiency and effectiveness of the NEOM tunneling project. By providing real-time insights into concrete strength, SmartRock served the consortium team to make informed decisions, improved their project timeline, and enhanced overall productivity.