The Project

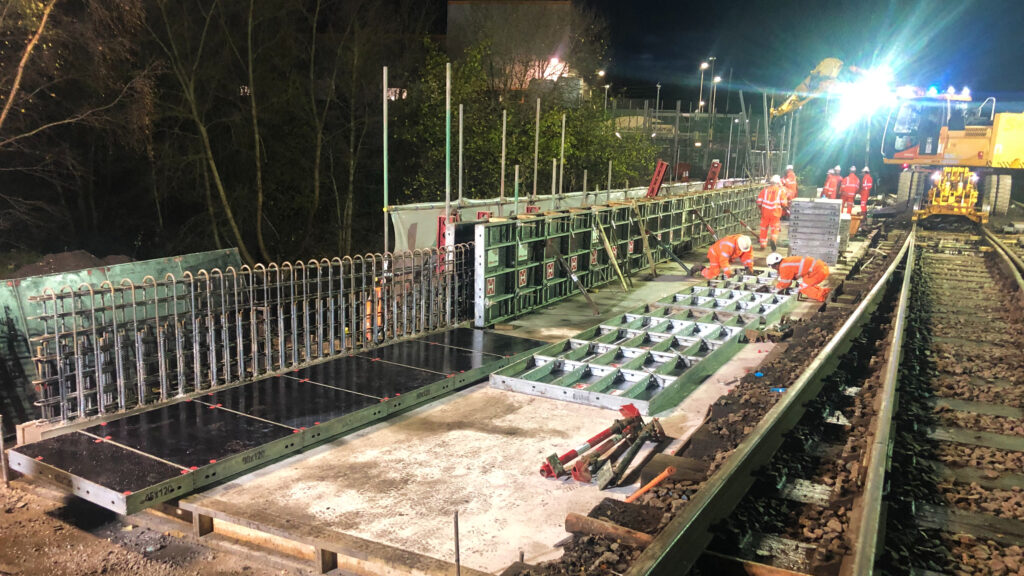

In 2022, the Petteril Bridge in Carlisle was damaged during the derailment of a freight train carrying cement wagons. The official reports indicate the derailment was a result of false flanges that caused rail wheels to stop rotating. Fortunately, there were no casualties nor injuries, but the accident did result in several weeks of line closures on the Newcastle route. Emergency repairs were carried out by Network Rail, the organization in charge of developing railway infrastructure in England, and for the repairs to succeed, the project required the removal and renewal of a deck and retaining wall. This had to be completed before the track could be re-laid, allowing the route to be reopened. Fortunately, Network Rail was able to contract Heidelberg Materials UK to take on the technical reins of the project.

The Clock Is Ticking, the Bridge Needs Stitching

One of the essential challenges for Heidelberg Materials UK was to provide a pumpable high early strength waterproof concrete mix that would achieve 50N/mm2 strength within a few days after placement. Additionally, the bridge deck required 38m3 and the retaining wall 15m3. To accomplish this, Heidelberg Materials UK was set to use its usual process of lab test cubes to determine concrete strength. However, the Petteril Bridge project required fast decision-making, not only for the route reopening but, most importantly, for monitoring high early-strength concrete. Waiting for cube test results would pose a significant challenge due to the long wait times and delays.

SmartRock® Is the Perfect Fit for High Early-Strength Concrete

In order to meet the requirements of time and strength, Heidelberg Materials UK had the perfect ace up its sleeve, SmartRock® concrete sensors. Heidelberg Materials UK provided high early strength concrete and technical assistance for which SmartRock was essential for its success. The wireless sensors provided strength data 24/7 and in real-time, avoiding the delays of cube testing results. The rapid availability of this data was crucial as it can monitor the specific strength needed for early-age concrete, which differs from other kinds of concrete.

Heidelberg Materials UK easily rolled out the sensors for the deck and the retaining wall and this addition quickly became a great advantage when it came to reviewing concrete data on-site during the curing process. The SmartRock mobile app was optimal for project managers as they could review real-time strength data with a user-friendly interface. Better yet, Heidelberg Materials UK also brought to the table the Giatec 360™ dashboard to distribute PDF reports of the operations among Network Rail and the parties involved.

Repairs Completed in Record Time

By using the complete functionalities of SmartRock and our Giatec ecosystem in the repairs of the Petteril Bridge, Heidelberg Materials UK was able to deliver results that satisfied and impressed the government client and community. With no delays and confidence in the quality of the repairs, the Petteril Bridge successfully reopened only 7 weeks after the derailment. As reported by Network Rail, around 125 tones of structural concrete were poured into metal reinforcement cages, and over 40 people worked on the clock to ensure the safe reopening of the Newcastle route.