Unique $40 Million Music Venue

For almost 80 years Hilltop has provided the construction industry with high quality materials. The company prides itself on being at the forefront of technology and tries to “push for ways to help” customers says Brett Deters, Technical Services Manager at Hilltop Companies. When Baker Concrete, one of the largest and most respected concrete contractors in the U.S., needed recommendations from a trusted, high-quality ready-mix supplier for the prestigious Ovation project in Newport, KY, they immediately turned to Hilltop.

PROBLEM

Ovation is a 25-acre mixed-use facility in Newport with a massive indoor/outdoor concert venue, 900 residential units, restaurants, retail, hotels, offices, and 550-car parking garage. High performance concrete with low shrinkage was specified for maximum durability and strength as well as reduced cracking.

An aggressive schedule with several large pours was also planned in part because a competitive concert venue was being developed across the Ohio River in neighboring Cincinnati. “There was sort of a race going on,” says Deters, with some pressure to be the first to open. As a result, Baker Concrete wanted to reach targeted compressive strength of 3,000 psi in 2 days rather than the 3 days stated in the engineering specs.

SOLUTION

Hilltop Recommends Concrete Maturity Sensors

Although field-cured specimens were required on the Ovation project for validation purposes, Hilltop recommended Baker Concrete use maturity for confirming in-place strength of concrete to meet their desired 2-day specs. “Any time a contractor comes to us and they’ve got a 3-day requirement or less, we always recommend maturity,” says Deters.

Maturity is a non-destructive, and reliable method for estimating in-place concrete strength using sensor data. For Deters, maturity is the most accurate way to know what’s going on inside placed concrete versus using traditional field break test cylinders. “We can put these sensors in and tell you exactly what’s going on in your concrete; and that’s what you want to know,” he says.

In comparison, field specimens are not stored and maintained in the same conditions as in place concrete. Nor will they exhibit the type of heat that is generated from a large mass of concrete. As a result, cylinders can provide conservative and inaccurate estimates for the strength of in-place concrete.

‘The Best’ Maturity System

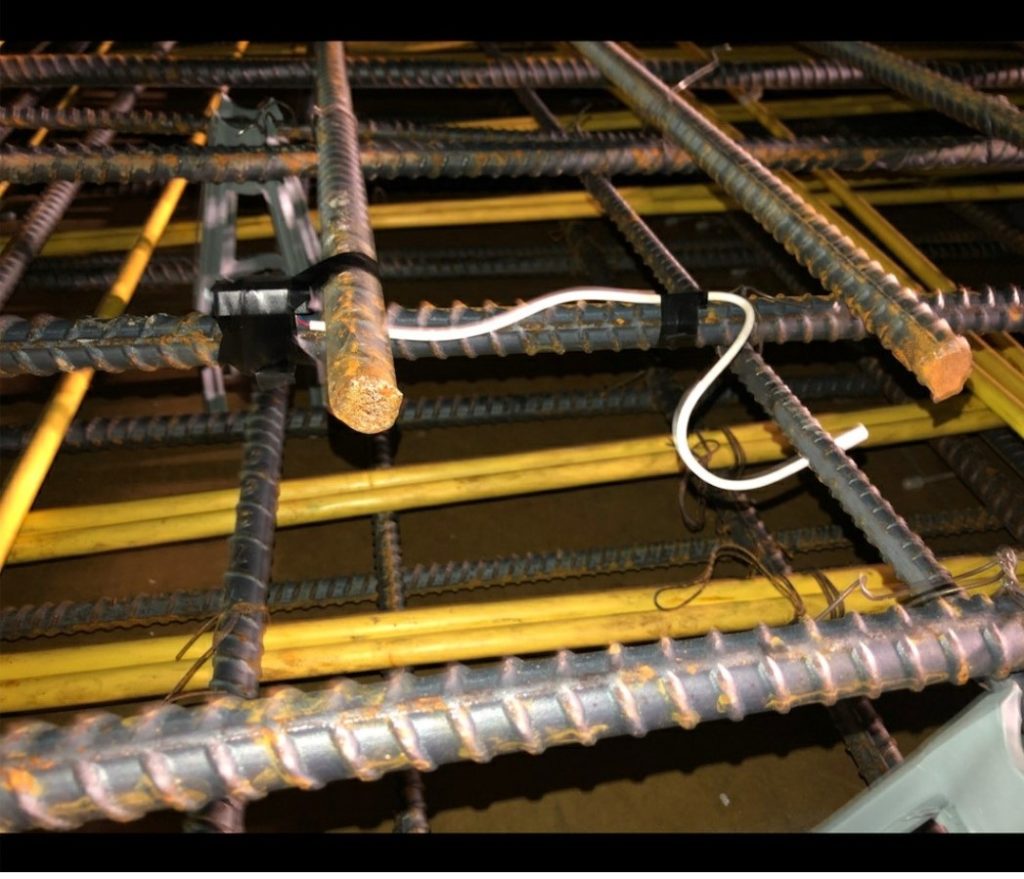

For Hilltop, maturity means SmartRock Plus. “We don’t ever talk about other maturity systems,” says Deters, “this is the best one.” SmartRock Plus is a value-added solution recommended by high-quality ready-mix producers like Hilltop. Wireless sensors are embedded by contractors in their concrete, providing valuable real-time data on the performance of their mixes. Producers simply calibrate each mix for strength using the maturity method (ASTM C1074). Strength and temperature data are automatically uploaded to the SmartRock Plus cloud and easily accessed using a mobile app.

SmartRock Plus gives contractors much more independence and eliminates delays from waiting for lab results. “Baker pointed out to me that their guys liked being in control of putting the sensors in and getting the readings themselves,” says Deters. “A lot of these guys are self-sufficient – they don’t want us to have to come in and hold their hand all the time,” he says. Baker’s field team also reported that SmartRock Plus was “very easy to put in” and “definitely liked that it worked – they stressed on time every time.”

3 to 4 Sensors per Pour

For the Ovation project, Baker Concrete ended up using a total of 9,000 to 10,000 yards of concrete. The schedule involved several large pours of 700 yards, although some were as small as 180 to 200 yards. To meet ASTM standards for the maturity method, a minimum of one sensor is required for 5,000 sq. ft. or 150 yards, whichever is smaller. For Ovation, this resulted in an average of three to four sensors for most pours and a total of 25 to 30 pours with maturity.

RESULTS

“We only use the best products because we don’t want to let our customers down…when we talk about maturity, we mean SmartRock® Plus…we would never use anything else…we don’t ever talk about other maturity systems: this is the best one.”

Brett Deters, Technical Services Manager, Hilltop Companies

Strength Made in 2-Days or Less per Pour

“We never once had a problem with making strength when they wanted it,” confirms Deters. “We made it every single time in 2 days or less – a lot of times we made it in 1 day!” Deters adds that making strength so quickly was in part because Baker used a corrosion inhibitor to extend the lifespan of the concrete, specifically calcium nitrate which also acts as a concrete setting accelerator. “Strengths were off the charts high,” says Deters.

Completed On-Schedule

Although Baker Concrete stressed on time every single time, and never had a problem with what they wanted to do, they still finished ‘on-schedule’ rather than ‘ahead of schedule’. “They said it had absolutely nothing to do with us, but unfortunately did not finish quite as early as they wanted to,” says Deters. Had Baker relied on field-cured specimens for determining strength, “it would have been worse time-wise [without SmartRock Plus], no question.” Deters says that Baker also “definitely saw savings” by not relying on field cures and the resulting lab work that would have been required.

Innovation and Leadership

The ability to show innovation and industry leadership is another reason Hilltop recommends SmartRock Plus. “We like being the best and being on the cutting-edge, and it’s the same way with a lot of our products,” says Deters. “We only use the best products because we don’t want to let our customers down.”

Clients Trust Hilltop

Deters says clients like Baker Concrete ultimately value Hilltop because of trust. “A lot of people will say, I just feel better when I buy from you. I know I’m not going to have problems with my concrete.” Recommending SmartRock Plus is one more way Hilltop builds trust one client success at a time. “We are concrete people, and this type of technology is a great thing,” he says. “We’ll continue to push this going forward.”