Innovation That Revolutionizes the Future of Construction

Lightweight Concrete Solutions, founded by Director Chris Calvin in 2015, is a leader in lightweight concrete, offering top-quality mixes to the industry. LWCS was the first to market lightweight concrete, shotcrete, and grout mix designs without admixtures to achieve full strength. Their focus is on developing the highest quality products for clients who hold “stringent standards for resilience, responsibility, and efficiency”.

Their lightweight mixes are high strength and low density. How is this done? By creating mixes that have a reduced mass and improved thermal and sound insulation properties which maintain adequate concrete strength. LWCSI’s high-quality lightweight concrete materials are extremely durable, and provide a weight reduction of up to 1000 kg/m³. Most of their mix designs achieve designed strength in 7 days or less, significantly reducing build time.

In addition to these mixes’ proven durability under pressure, LWCS’s materials use recycled content and natural materials, making them environmentally friendly. This helps reduce CO2 emissions and energy consumption on customers’ projects. LWCS’s mixes can be used in many applications, including dams, high-rises, highways, and more. Their mixes have been used on pilot projects in Alberta and Ontario and are expected to be used worldwide this coming year.

Testing Lightweight Concrete with The Most Accurate Strength Method: SmartRock

These high-tech lightweight concrete mixes are designed with the help of accurate strength monitoring equipment like SmartRock, the leading wireless concrete sensor for measuring the curing of concrete in real-time.

Calvin and his team of researchers have created a construction material that, like Giatec’s concrete testing solutions, will revolutionize the construction industry. With a lower mass and density, their customers benefit from a solution that cures faster than traditional concrete materials.

In order to design these solutions, the LWCS’s team must closely monitor the mixes’ properties to ensure targeted strength is accurate. This is done through controlled testing with the SmartRock sensors, allowing their customers to see accurate real-world results.

“I use Giatec sensors in everything we do. With our emerging lightweight shotcrete, grouts, and now our most recent addition of lightweight SCC mixes. It is very important to know how our lightweight mixes are performing” says Calvin.

Using SmartRock Sensors for Accurate Concrete Testing

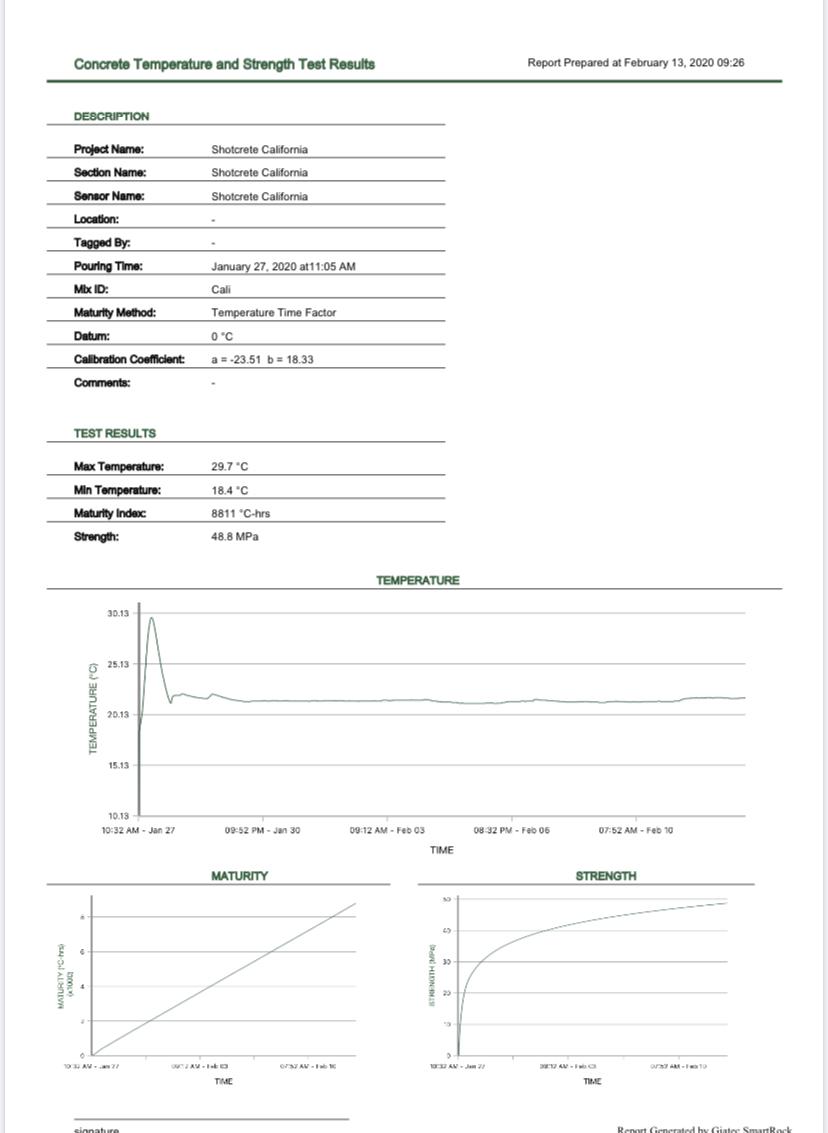

For Calvin and the LWCS team, the ability for SmartRock to provide them with accurate data on their concrete’s strength is of the upmost importance when designing their mixes. The SmartRock sensors are embedded directly in the testing cylinders, logging crucial data and providing them with “true readings of what’s going on in the concrete”. While monitoring the internal temperature and rate of curing of their mixes using the SmartRock sensors their test cylinders are subject to standard-cured and extreme field-cured conditions.

“I’ll put the sensor right into the cylinder. And I will actually break the cylinder with the sensor in it. And even after the cylinder has been broken. It’s still transmitting data. It’s still active. And that’s quality, right?”

Chris Calvin

The Advantages of Real-Time Monitoring

Calvin says using SmartRock sensors for monitoring concrete strength was an easy decision. With the sensors’ ability to remotely monitor strength using the SmartHub device, he can obtain real-time strength values at any time, from anywhere.

Not only that, the SmartRock sensors calculate concrete temperature and strength based on the maturity method, the most accurate method of monitoring concrete curing. This gives Calvin the confidence that the strength values he collects from the SmartRock sensors are extremely accurate. In fact, Calvin says they have a 0.3 to 0.5 MPa margin for error and this margin can be as low as 0.1 MPa at times.

With LWCS’s mixes and SmartRock’s method of monitoring in-situ concrete strength in real time, this high quality and durable concrete will allow you to feel confident that your structure stands tall and strong for years to come.