PROBLEM

About P.J. Hegarty & Sons

Established in 1925, P.J. Hegarty & Sons U.C. is one of Ireland’s most progressive building and civil engineering companies and the first construction company to achieve ISO 9002 status in Ireland.

Visit https://www.pjhegarty.ie/

In 2017 P.J. Hegarty & Sons were appointed as the main contractors for the redevelopment of the Electrical Supply Board (ESB) building at the Fitzwilliam Street site, Dublin.

The prestigious, high profile 45,000m2 development will be a near-zero-energy building and one of the most efficient and sustainable commercial office developments in Dublin city.

Temperature Monitoring and Break Tests Specified

Measuring temperature differentials was required to ensure optimal curing and to avoid temperature related problems that might affect durability or longevity. Internal temperatures needed to be within a specified range and under a maximum allowable differential.

In addition, break tests using “crushed cubes” was specified for confirming the strength of in-place concrete.

Wired Systems Not an Option

P.J. Hegarty & Sons had previously used thermocouples to monitor temperature on other construction projects. These systems use two wires which extrude from poured concrete and attach to a data logger.

Brendan Dunne, Project Manager for P.J. Hegarty, had several concerns about using thermocouples at the Fitzwilliam location. “The foot traffic and materials, especially with the slipform construction used at the ESB site, it would have been very difficult to protect those wires from damage,” says Dunne.

“So Much Work”

The time and labor involved to use thermocouples was also a concern. Dunne says they require someone “going down and connecting a logger to each sensor every day” to get temperature readings. Users must also create their own Excel spreadsheet to record readings and convert the document to a PDF for sharing. “It takes up so much time,” says Dunne.

Finally, Dunne notes that P.J. Hegarty is known for being an innovation and technology leader. “As a company, we are always looking to get the best technology that’s out there,” he says. “We need to get keep pushing to the next level.”

SOLUTIONS

SmartRock® is Chosen

Getting to the next stage for Dunne meant using wireless sensors immediately for temperature monitoring on the high profile ESB project. Dunne had used Giatec’s SmartRock while working on a project in Canada and rediscovered the solution online. “When I looked at your website, the new technology that you have developed is impressive,” he says.

Real-Time Monitoring

SmartRock results in robust, waterproof concrete sensors being attached to the concrete form work. Sensors provide instant wireless connection to a mobile device. A user-friendly app (iOS & Android) displays real-time temperature, strength, maturity information, mix calibrations, data history, and more. Data can be quickly shared with stakeholders through easy-to-read PDF or CSV reports.

RESULTS

Worked “Perfectly”

The ESB project resulted in 20 slabs being poured with an average two sensors per pour. “We had a specification to get temperatures for every slab – the mid height and near the surface – and SmartRock did that perfectly,” says Dunne.

Dunne also comments on the convenience of SmartRock. “I would get the temperatures each day and send a nice concise weekly report to the Structural Engineer right from my phone.”

Breaking Down Break Test Results

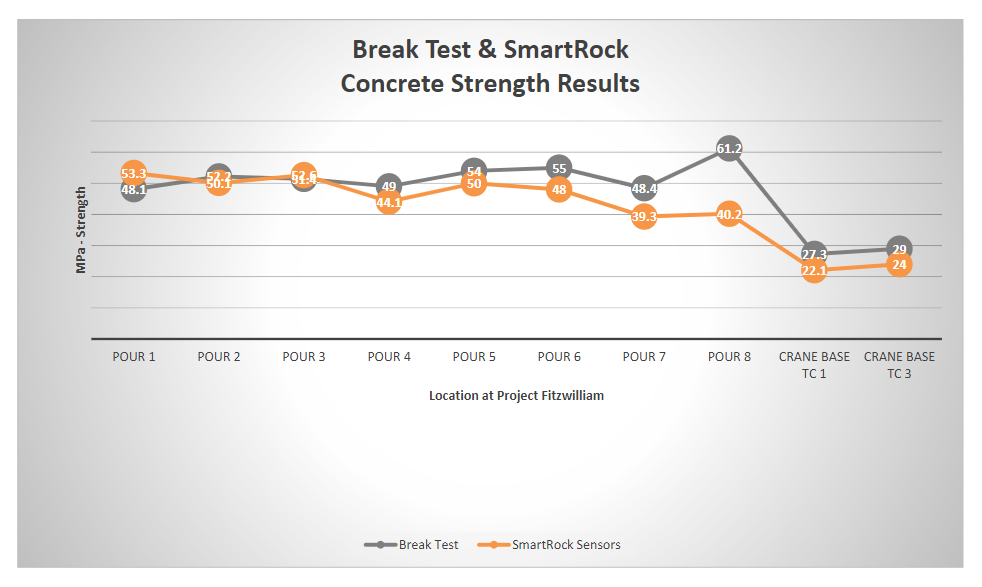

This chart represents the difference of strength values obtain from break tests at 7 days compared to the strength obtained from the in-place concrete through the maturity method using the SmartRock sensors. The goal of this test was a proof of concept to show that maturity was an alternative way to measure strength accurately within the structure without needing to rely heavily on cubes.

It is interesting to point out the difference in results for ‘Pour 8’, where the strength values obtained with the maturity sensors were overall more consistent than the break tests which showed abnormally higher results. This demonstrates the consistency and accuracy of the maturity method and this technology.

Ideal Opportunity to Test SmartRock for Strength

Although SmartRock accurately estimates concrete maturity based on the ASTM C1074 specifications for concrete, Dunne notes that crushed tests are the current standard for determining strength in Ireland. “That was in our specifications – we had to test using a third-party laboratory,” he confirms.

However, Dunne saw the ESB project as an important opportunity to test the accuracy of maturity using the SmartRock sensors against traditional lab break tests.

Dunne says that he did roughly 13 pours that were used to compare cube tests and SmartRock sensor results. Dunne confirmed that the temperature data provided by SmartRock’s sensors were nearly identical. Dunne says with the SmartRock sensor, “you’re getting a lot more accurate and useful information than you do with a break test.” Table 1 (below) summarizes the test results and the relative benefits of using SmartRock for strength when compared to laboratory break tests.

| Break Test | SmartRock Sensor |

| Information taken from cubes on site and crushed by compression machine. Results can be affected by mishandling of cylinders on site, during transportation or due to poor execution of work at materials laboratory. | Information gathered with embedded sensors recording temperature and strength in real-time. Data logged without interruption, so results are generally more consistent. |

| Temperature may differ due to curing conditions causing a different rate of strength gain which results in low or high breaks. | Maturity method predicts the actual in-place strength of concrete. |

| Takes time to send samples to and from laboratory. | Strength is collected instantly in real-time. |

| Cost to cast, collect, test, and repeat for each pour. | Major cost savings for determination of in-place strength of concrete done by one engineer/manager on site. |

| Waiting for results of cube break tests and transferring reports is slower. | Quick data transfer between parties. |

Transitioning to the Maturity Method

Dunne says P.J. Hegarty endeavors to move away from thermocouples in favor of using SmartRock for temperature readings. Using SmartRock for concrete strength instead of breaking cubes “is going to take more time” he says. “Everyone involved was impressed [with SmartRock] but again, this is a conservative industry and we have to go by what a Structural Engineer specifies.” In most cases, break tests are still specified in Ireland. “It’s a transition,” says Dunne.

The ‘Real Deal’

As an interim step, Dunne sees an opportunity to use SmartRock on future projects to complement crushed cube lab testing. For example, instead of having to wait 7 days before applying load, he sees the potential to use SmartRock’s real-time results to do crush tests sooner if sensors show that specified strength has been reached.

“They save a lot of time. They are accurate. SmartRock is the way forward,”

Brendan Dunne, Project Manager, P.J. Hegarty