The Data Management Dilemma

In the competitive and rapidly evolving material supply industry, Ottawa-based concrete supplier Tomlinson Ready Mix found itself facing a pressing challenge: managing the increasing complexity of concrete mixture designs and data while meeting stringent quality standards and delivery timelines. Despite their best efforts, Tomlinson’s reliance on manual data management methods, including physical folders and customized spreadsheets, proved to be inadequate and unsustainable as the company expanded its operations. While Tomlinson’s transition to online spreadsheets was an attempt to modernize their data management processes, they soon found themselves unable to keep pace. Lacking integrated analysis capabilities, Tomlinson’s team spent excessive time on data entry and manipulation, detracting from their focus on strategic decision-making and innovation.

Tomlinson Ready Mix Embraces the Digital Journey!

Recognizing the need for a comprehensive digital solution, Tomlinson Ready Mix decided to implement Giatec SmartMix™, an AI-powered mix management system developed by Giatec. SmartMix offered Tomlinson a holistic solution to their challenges, providing a centralized platform for data storage, analysis, and optimization. One key aspect of SmartMix that appealed to Tomlinson was its ability to validate concrete mixture improvements that they didn’t have the time or data to explore before. Prior to SmartMix, Tomlinson’s team tried implementing a standard quality control system to consolidate and analyze their concrete performance data. However, it did not yield enough valuable insights to justify the time spent on manual data entry. Consequently, the team relied on intuition and experience to make decisions about mix designs. While initially testing SmartMix, they immediately saw the benefit; “SmartMix is actually worth spending the time putting in the data and increasing my testing because I now get immediate, valuable information that can make a direct impact on my mix.” Comparing historical performance data with current concrete mixtures allowed Tomlinson to identify trends that confirmed their existing knowledge while also uncovering new insights.

Reducing 35kg Cement With No Trials in Just 6 Weeks!

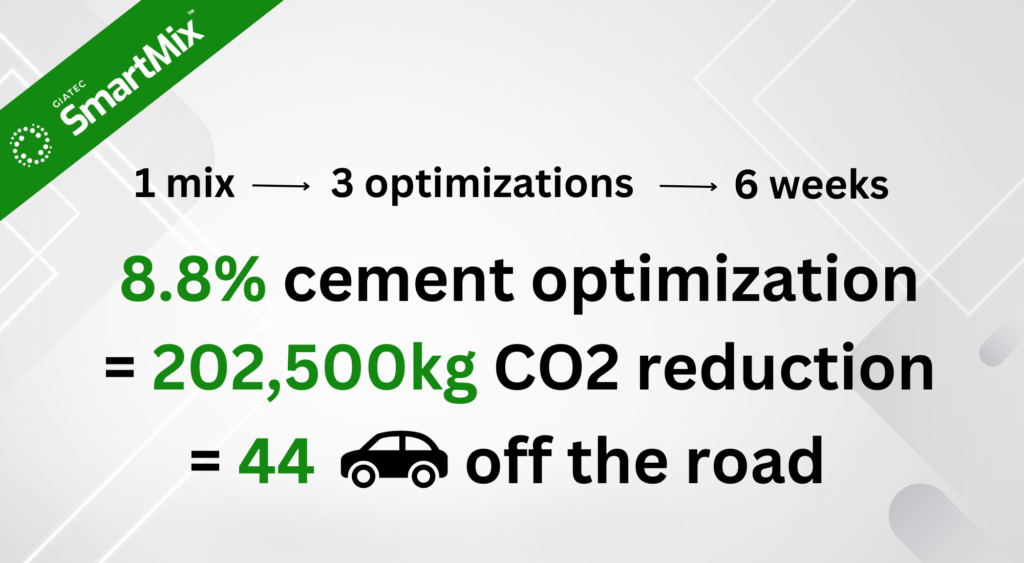

Since implementing SmartMix, Tomlinson has realized substantial savings, both financially and environmentally. In one project, Tomlinson was brought in as a secondary supplier in later stages, with the client requiring 100% design strength in 7 days. To meet demands quickly, Tomlinson intentionally overdesigned (as we all do!) and was able to confirm in SmartMix that this was being achieved in 3 days. Hence, making it clear there was room to optimize. With Roxi’s insights, Tomlinson made 3 incremental mixture adjustments, cutting a combined total of 35kg/M3 in just 6 weeks. This reduction translated directly into cost savings, without compromising on performance or quality. SmartMix allows for both big-scale optimizations and smaller incremental adjustments. In Tomlinson’s case of operating in a relatively performance-based market, they were able to see smaller adjustments. Those adjustments represented 2% cement decreases at a time, leading to an 8.8% cement reduction and a 5% cost reduction. Not only did Tomlinson save money in real-time, but they also now have this mix ready for the next job.

Tomlinson Ready Mix’s Experience With Giatec’s EA Program

Tomlinson’s involvement in the EA program was a positive experience marked by constant communication and feedback. They appreciated the collaborative environment where the Giatec team actively considered and addressed their ideas. This allowed them to contribute to the development of SmartMix, making a real impact in the industry. However, this collaboration represents just the beginning. Giatec’s commitment to revolutionizing the construction industry involves continuously collaborating on a larger scale and introducing innovative solutions. As Tomlinson observed, “Giatec is using technology to solve concrete problems, not trying to apply technology to problems they do not know.”

Optimizing Concrete Mixtures for a Sustainable Future

Looking ahead, Tomlinson anticipates further benefits from SmartMix. They aim to optimize concrete mixtures for projects such as curbs and sidewalks, making incremental adjustments for significant improvements. By leveraging SmartMix’s analytics capabilities, Tomlinson can continuously enhance their mix designs, even in challenging conditions like Ottawa’s winters. Additionally, Tomlinson sees SmartMix as a tool for driving sustainability initiatives, potentially reducing environmental impact and addressing global warming potential.