Andrew Fahim, Head of Research & Development at Giatec, to Lead Development of Corrosion Testing Methods.

Ottawa, Canada: Giatec, world leader in concrete testing technologies, has announced that their head of research and development, Andrew Fahim, M.Sc.E., has been chosen to join the ASTM WK68960 and ASTM G01.11.5: “New Test Method for Measuring Corrosion Rate of Uncoated Reinforcing Steel in Concrete” committee.

As no standard currently exists, this ASTM committee has been established to review and standardize proposed methods that will be used to measure the corrosion rate of uncoated reinforcing steel in field and laboratory concrete.

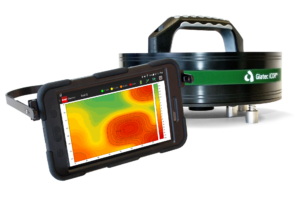

Giatec’s authority in the field of concrete testing and corrosion detection led to Mr. Fahim’s appointment to the ASTM committee. Last year, the company’s non-destructive testing device, iCOR®, the most advanced wireless corrosion measurement device for evaluating the health of reinforced concrete structures, was presented the 2019 Corrosion Innovation Award by the National Association of Corrosion Engineers (NACE | website: https://nace.org/).

The iCOR uses patented CEPRA technology to provide unprecedented levels of accuracy, detecting the health of concrete structures in a matter of seconds. Other detection systems to assess corrosion must physically attach to rebar by drilling into concrete, or through other invasive means. The iCOR can measure the condition of major structures without damaging them or compromising their integrity.

“I am very excited to lead ASTM’s efforts on standardizing the measurement of rebar corrosion rate. At Giatec we deeply believe in the role that standards play in the construction industry and contributing to these standards is a big part of our vision” says Mr. Fahim.

Monitoring and inspecting reinforced steel for corrosion is done in concrete structures, particularly bridges, to locate areas with corrosion activity, predict future damage, identify areas in distress due to corrosion, and plan for repair and rehabilitation strategies.

ABOUT GIATEC

Giatec Scientific Inc. is a global company revolutionizing the construction industry by bringing smart testing technologies and real-time data collection to the forefront of every jobsite. Giatec’s suite of hardware & software products has leveraged advanced technologies such as; Artificial Intelligence (AI), and Internet of Things (IoT), including; wireless concrete sensors, mobile apps, and advanced non-destructive technologies (NDT) to drive innovation?throughout concrete’s lifecycle. For more information visit www.giatec.ca.