Giatec is launching a first-of-its-kind simple and accessible Thermal Model feature through their Giatec 360™ platform to better predict concrete temperature in mass concrete elements.

OTTAWA, Ontario – Giatec®, world leader in concrete testing technologies, is officially launching a Thermal Modeling feature on their Giatec 360™ platform to predict the maximum concrete temperature and temperature differential of mass concrete.

Thermal Modeling is a comprehensive solution for engineers, general contractors, and ready-mix producers. The feature allows users with mass concrete elements to experiment with different inputs and produce forecast scenarios outlining the anticipated behavior of the concrete temperature at various depths.

“Central Concrete has been partnering with Giatec for the past few years to develop models that provide project-specific thermal projections, which help us make sure our mixes meet building code thermal requirements,” says Patrick Frawley, Director of Quality Assurance at U.S. Concrete. “This software has helped Central Concrete simplify the mix design submittal and acceptance process on our most complex projects.”

“The Giatec team is excited to announce the release of the new Thermal Model feature, built with our customers in mind. Intended to work independently of our SmartRock® sensors, it is user-friendly and intuitive, needing no specialized training. We also invite our Giatec 360 subscribers to provide their feedback for future feature development,” says Pouria Ghods, CEO and co-founder of Giatec.

This user-friendly feature can be leveraged by multiple stakeholders to optimize planning, save time, validate important decisions, and more. By specifying concrete pour settings, mix design, and element design, Giatec 360 now offers:

- Optimized planning of mass concrete pours.

- Validated cooling needed for pouring temperature requirements.

- Building thermal control plans.

- On-the-fly mix design changes or alternative options to meet temperature requirements.

- Unlimited mix design iteration without physical testing.

- Time and cost savings.

- No need for expensive modeling or complex DYI computation.

- ACI 207.2R compliant calculation guidelines.

The Giatec 360 dashboard is the next level in data analytics, reporting, and user management capabilities for SmartRock sensors. These user-friendly sensors are easily installed in the concrete formwork to monitor your concrete’s in-place temperature and strength in real-time. This information is then synced on the Giatec 360 dashboard giving users access to numerous features that provide more insights into their projects than ever before.

About Giatec

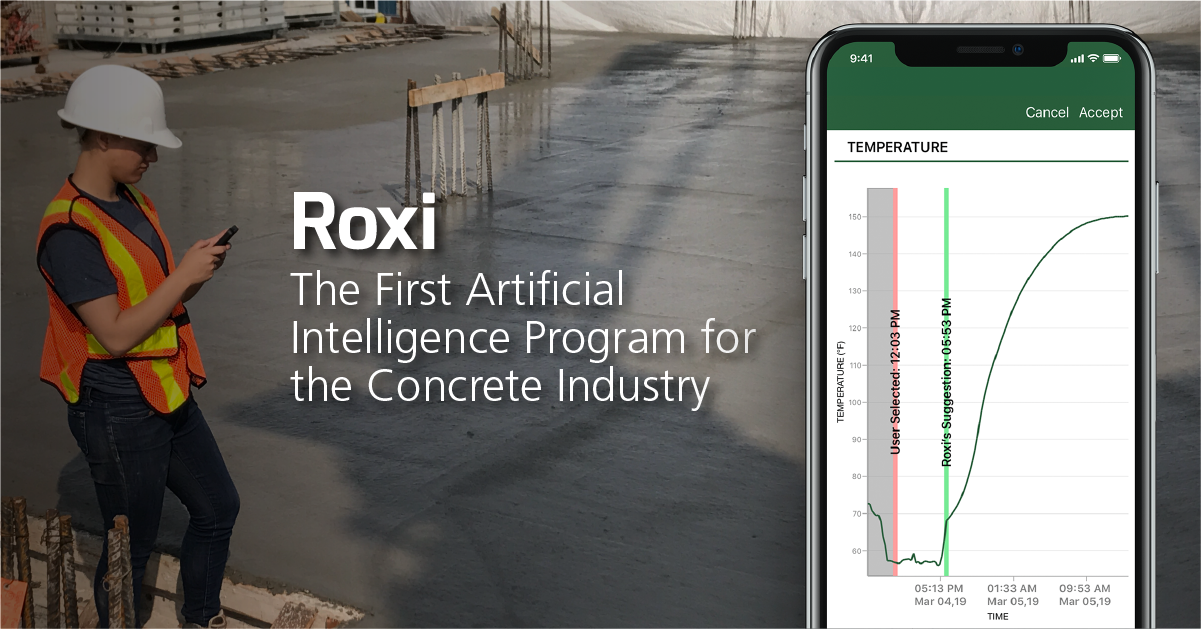

Giatec is a global company revolutionizing the construction industry by bringing smart testing technologies and real-time collection and analysis of concrete data from production and delivery to placement. Giatec’s suite of hardware and software products has leveraged advanced technologies such as Artificial Intelligence (AI) and Internet of Things (IoT), including wireless concrete sensors, mobile apps, and advanced non-destructive technologies (NDT), to drive innovation throughout concrete’s lifecycle and reduce concrete’s carbon footprint. For more information, visit www.giatec.ca.