Second High-Profile Tech Award Won in 2019 for Concrete Testing Leader

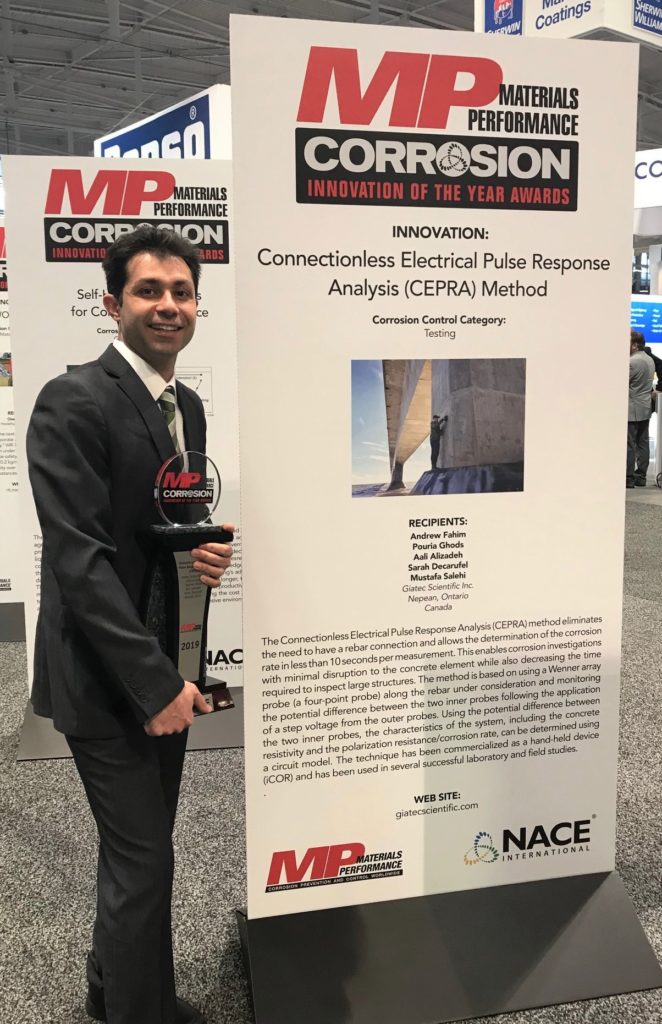

NASHVILLE, Tennesse: Giatec’s iCOR®, the most advanced wireless corrosion measurement device for evaluating the health of reinforced concrete structures, was presented the 2019 Corrosion Innovation Award by the National Association of Corrosion Engineers (NACE). The award was given at Corrosion 2019, the world’s largest event for the prevention and mitigation of corrosion.

“For decades, the quick and accurate measurement of corrosion rates has been a challenge for engineers across the globe”, says Pouria Ghods, Co-Founder of Giatec. “We are honored to receive this award and be recognized by our peers after years of research efforts; it tells us we are solving key problems with cutting-edge technology.”

Other detection systems to assess corrosion must physically attach to rebar by drilling into concrete, or through other invasive means. The iCOR® can measure the condition of major structures without damaging them or compromising their integrity. And unlike other systems, engineers are given instant access to a visual corrosion map directly on site through a mobile app.

Giatec’s technology also detects problems in existing concrete structures much earlier than other methods, while predicting the rate of future deterioration. The iCOR® has been used in the condition assessments for the Federal Bridge Corporation, Public Works Canada, CTL Group, and during imperative forensic analysis, such as the shopping mall roof collapse in Elliot Lake, Ontario.

“The iCOR® has proved to be robust on-site and I am confident in the results that I see. My favorite feature is that data on corrosion rate, concrete resistivity, and half-cell potential can be recorded simultaneously. This information is essential when interpreting the rate of corrosion deterioration”.

– Dr. Jose Pacheo of CTL Group.

The recognition comes less than two weeks after Giatec’s SmartRock® was crowned the Most Innovative Product at World of Concrete for 2019. SmartRock® is the world’s leading wireless concrete sensor for measuring temperature and concrete maturity on-site.