Re-Designed SmartRock Delivers Breakthrough Innovations to Every Jobsite

Las Vegas, USA: Giatec, world leader in concrete testing technology, announced today at World of Concrete 2020 that their flagship product, SmartRock®, has been completely re-designed, making it the World’s most powerful concrete sensor on the market.

As the first truly wireless sensor introduced to the market in 2015, SmartRock® is the leading concrete maturity sensor for accurate monitoring of concrete curing and hardening. Unlike time-consuming and error-prone break tests, or cumbersome wired sensors, Giatec’s patented maturity sensor uses a highly accurate ASTM-approved testing method. This has translated into faster, safer, and more economical concrete construction – even in extreme weather conditions.

We’ve been able to save owners and contractors tons of time and money with SmartRock since 2015 and are impressed with the continuous improvements of both the hardware and software” says Walter Flood, Principal Engineer, Flood Testing Laboratories. “It is our go-to technology for every concrete project.

The newly engineered SmartRock sensor takes concrete testing to a whole new level. The sensor’s wireless signal range is now 5 times stronger and is able to collect data from 40 feet away through concrete with the option to access data remotely via a local hub. With a complete revamp to the sensor’s design and updated activation and QR code tagging method, this truly wireless, fully embedded device is even more hassle-free, robust, and secure.

Key features updated with this premium SmartRock sensor include;

- Re-engineered sensor: simpler to implement and use onsite.

- New mobile application: completely rebuilt using input from 7,000 monthly active users.

- Enhanced cloud-based dashboard: easily manage all projects in one place and gain deeper insights into the performance of concrete projects at every stage.

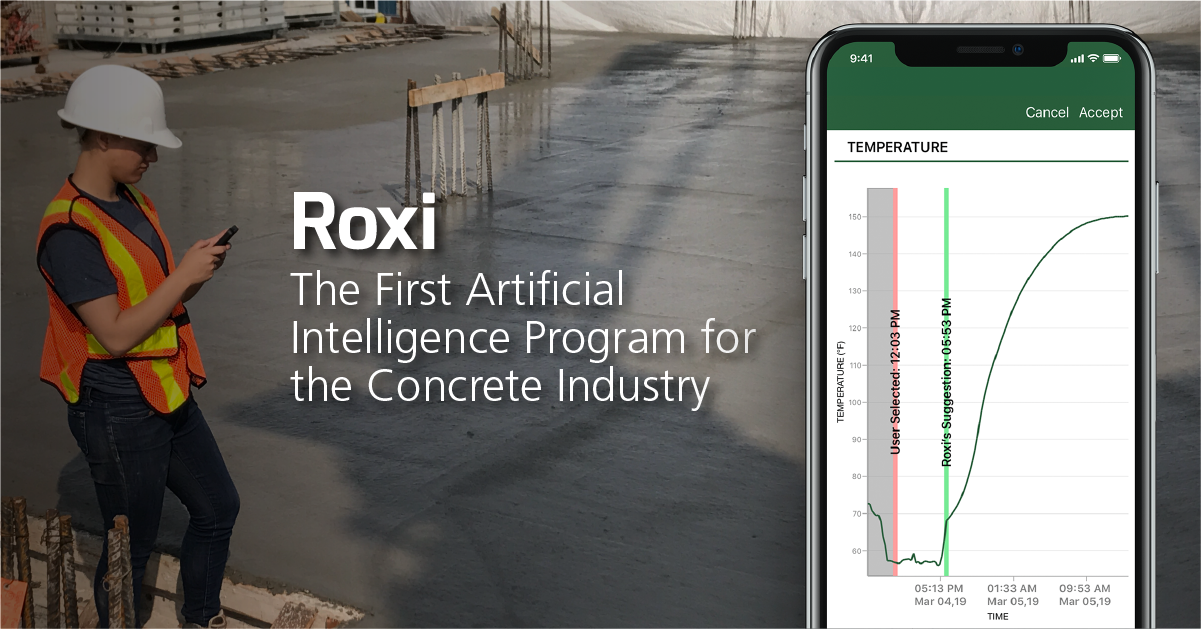

- More powerful artificial intelligence assistant, Roxi: eliminates human error by giving the upmost confidence in mix calibration data and in the accuracy of strength test results.

- New REST API interface: introducing the ability for more applications to link with the Giatec concrete testing platform.

This more advanced sensor will make it 10 times easier for our customers to use. Plus, additional functionality added to Giatec’s artificial intelligence tool, Roxi, helps us eliminate human error,” says Patrick Frawley P.E, Director of Quality Assurance Central Concrete Supply, U.S. Concrete Inc. “We’re excited to get it out on the field.

SmartRock is helping top construction companies eliminate concrete testing delays and take back control of their schedules in over 5,200 projects across 45 countries. World of Concrete 2020 attendees can view this newly engineered product this week, from February 4-7th, at the Giatec booth #N1451 in the North Hall.

MEDIA CONTACTS

Dobrila Moogk, Vice President of Marketing

Tel: +1 (877) 497-6278 ext. 9280

marketing@giatec.ca

www.giatec.ca