Episode 13 |

July 22, 2021

A Deep Dive Into Giatec’s SmartRock Wireless Concrete Sensors

In This Episode

In this episode of Construction Revolution, we spoke with Sarah McGuire, the Senior Director of Sales at Giatec Scientific Inc., where she leads the company’s sales and business development to drive its mission to revolutionize the concrete industry. The company's revolutionary concrete testing technology is now being used in thousands of projects across 85 countries and has been on Canada's fastest growing companies list for three years running. Sarah built Giatec's channel partner network to drive demand for “internet of things” sensors within emerging markets and has developed programs to help clients succeed with using advanced concrete testing technologies. She is now leading the sales efforts and members within the North American market. Giatec is well-known for its SmartRock wireless concrete sensor, and in this episode, Sarah provides a detailed look into the mechanisms of the SmartRock product, an explanation of the maturity method in relation to the function of the sensors, as well as tips and tricks to obtain concrete strength estimation in the most efficient way possible.

Host

ERIC YEE

Content Marketing Manager, Giatec Scientific Inc.

Guest

SARAH MCGUIRE

Senior Director of Sales, Giatec Scientific Inc.

Podcast Transcript

Eric Yee:

Hello there and welcome to the Construction Revolution Podcast. My name is Eric Yee, and here on the show, we explore the latest trends, technologies, people, and organizations that are revolutionizing or disrupting the construction industry and changing what the industry will look like tomorrow. Today on the show, I’m speaking with Sarah McGuire, the senior director of sales at Giatec. Sarah leads Giatec sales and business development on its mission to revolutionize the concrete industry.

The company’s revolutionary concrete testing technology is now being used in thousands of projects across 85 countries and has been on Canada’s fastest growing companies list for three years running. Sarah built Giatec’s channel partner network to drive demand for internet of things sensors within emerging markets and has developed programs to help clients succeed with using advanced concrete testing technologies within conventional settings. Sarah is now leading the sales efforts and members within the North American market.

Sarah, Giatec is well-known for its SmartRock wireless concrete sensor. Can you explain what the SmartRock is and why someone would want to use them?

Sarah McGuire:

Yeah, Eric, it’s a great question to kick it off. So the SmartRock sensors are the latest version of wireless technology being included with the maturity method. Maturity for estimating concrete strengths has been around in standards since the ’60s. But until Giatec came out with our technology back in late 2015, and until then, no one had really taken the time to review this methodology and see how we can take the technology of today and actually make it more practical to be used in job sites.

Essentially, the sensor is put into the concrete and using the maturity method, using the time and temperature curve, it’s basically saying that if I’m using the same mix at this… If I’m using the same mix and it’s generating a certain keep profile, that with the same mix with this heat over this time, my strength will always be a certain value. So then you create that baseline. When you use the sensors, they’re just taking basic temperature.

But when you put the sensors into the concrete and you’ve done that baseline with the previous mix, you are now saying, okay, I’m putting my sensor into the concrete, getting the actual curing conditions of the slab. And depending on how hot it is and how hot it’s curing, that temperature profile is either going to generate at a higher rate or a lower rate and give you that strength. The sensors that we have, they’re very easy plug and play sensors that connect with your mobile phone. And that’s really all it is.

This is allowing contractors to essentially not have to spend so much time waiting for maturity breaks to come back, playing a guessing game if things go wrong. They’re able to accelerate their job site. They’re able to accelerate their schedules. They’re able to get all of their data in real-time with the strengths and be able to make more proactive decisions on site and just take a lot more power back into their hands.

But also because of the technology of having all of this data stored up in the cloud, it is not only just shared with them, but it can be shared with the engineer on record, the owner, the GC or the sub, depending on which one they are. Even the ready-mix companies that want to be able to get some insights into their own concrete so they can better serve their clients. And of course, the testing agencies, because from time to time, people will want to crush a verification cylinder to make sure that the maturity is reading well.

Imagine you’re sitting in the lab. You get a notification because the sensor is installed, crush that cylinder. You say, “Okay, we’re going to go,” and it just makes things a lot more efficient on site.

Eric Yee:

Speaking about like onsite, how easy are these sensors to install?

Sarah McGuire:

Giatec, we came out with a newer version of the sensor. Before we would have said, of course, they’re plug and play, very easy to go. But of course, when you come out with a product, you know that it works really well. But on job sites, things are chaotic, so we need to make things as simple as possible for people. That’s what we’re always trying to do to better ourselves. The sensors that we have now, they actually have a groove kind of underneath the bottom of the sensor and a rubber strap that holds up to 40 pounds.

I can barely move at myself. You’re able to just attach it right into the rebar, and it secures on its own. Before the older version, we would have to secure with tape or zip ties. But now the newer version of the sensor, that rubber strap is going to do the job for you. The temperature cable will actually come out of the body. Once you remove that from the body, it’ll flash three times in green to let you know that everything’s working fine. And then you will put that temperature probe where you actually want to pick up that reading.

We have a SmartRock. The rock version or the body, so to speak, that we want to secure onto the rebar to make sure that it’s embedded properly and giving a strong signal from the sensor to your phone once embedded. Usually you’re going to get about 40 feet with the newer versions of our sensors from the sensor to the phone. And then that temperature probe, you are going to place that where you actually want to take the temperature measurements. And that way, you’re not confined by Bluetooth signal to get those deeper points that you want to get.

Eric Yee:

The Bluetooth can kind of get things that are on the surface, but the deeper probe can get you like maybe your core temperature.

Sarah McGuire:

Exactly. The sensors do come in a couple of different lengths. We have ones that are a foot, 12 inches, or we have one that are 10 feet. We do have longer ones, but 95% of projects, they don’t need to get into those custom lengths. 10 footers will usually do the job.

Eric Yee:

Temperature is such an important thing when you’re talking about like concrete and curing concrete. How do the sensors work in say hot weather and cold weather? Are there any kind of performance differences?

Sarah McGuire:

Not really. When you’re just looking for temperature, of course, we have specifications around the sensors of not to be used in less than minus 40 and not to be used in higher than I think it’s 100 degrees Celsius and 150 degrees Fahrenheit. It’s pretty astronomical what those heights are. Actually, I think I’m even misspeaking. I think it’s even higher than that. But of course, it goes way higher than what we would actually see concrete perform in. We’ve used our sensors in places like Alaska in very intense cold weather.

I mean, Eric, we are located in Ottawa, Canada. We won the award for being the coldest capital city in the world last year. So obviously we’ve tested them in our conditions, but we also have a lot of customers in the Middle East that are using these in the dead of summer and they have no issues with them whatsoever.

Eric Yee:

One of the things you mentioned was that SmartRock, the tech is based on the concrete maturity method. I think you said it’s standard. What exactly is the maturity method? You said it’s been around since the ’60s?

Sarah McGuire:

Yeah. The maturity method, it’s been invented… A fun fact that I like to pull out because we’re located where we are is that the first building to ever truly use maturity from beginning to end to accelerate schedules was actually the CN Tower in Toronto. And that finished I believe in 1972 or it began in ’72 and finished in ’76, but they claim to have saved… If they had to stick with a regular stripping schedule, they probably saved months on that project, but they were actually able to get a three-day turnaround. In the ’70s, that is astronomical.

We have many projects to this day that are still not getting that three-day turnaround, because they’re just over-designing or overestimating to make sure that they’re okay. It has been around for a very long time. The issue is that the technology that people used, it wasn’t very robust or very simple. So using maturity on some of these projects, you would have to dedicate a few technicians to go out there, install the sensors, and then plug an individual reader into the sensors physically.

You’d get a small readout, but then you’d have to take it back to the portable or the lab or wherever you’re going. A lot of times people were writing things manually down I believe in the ’70s. Everything obviously would have been manual at that point. It wasn’t really until the ’90s that this became commercialized, but still the technology wasn’t really there. People were using it on really big projects where it was worth it, especially high profile where if you don’t finish on time, you’ll have a lot of public scrutiny for that.

But it wasn’t being applied across the board because it seemed too complex to do. But maturity is essentially you’re just taking the temperature. You’re basing the strengths on temperature. Because what we get with cylinders, when we are taking cylinders and curing them on the side to try and replicate what’s happening in the larger, massive concrete beside, it’s just not…

When you think about it logically, you don’t need to be a concrete PhD like our founders to realize that a small mass of four by eight cylinder is not going to cure at the same rate as a 300 cubic yard pour. I mean, it’s like having a big lake beside a small pond in the hot summer. The little puddle beside you is obviously going to be closer to the ambient temperature, but the lake is always going to be cool for you to obviously cool often. It’s really the same thing with the cylinders and the pores.

What this maturity method is doing is allowing you to put a sensor in the middle of the pore to get that actual temperature, and then using a calculation of your temperature and time based on a specific mix. You’re saying that this mix will always cure to be this strong if it’s curing at this temperature with these ingredients. It’s essentially just setting that baseline so that once you put in a temperature probe, you’re able to use that calculation to get your accurate results.

And although it is an estimation, and I think that’s why we have a lot of people that are still quite skeptical because, of course, there are things that can go wrong in doing a calculation, but because you’re actually taking the real events of what’s going on in the concrete, when the calibration or the mix is calibrated properly, your results are actually going to be a lot closer to if you were to core directly from this lab. We’ve proven that time and time again. ACI chapters across the country have done various tests that we’ve worked on with them.

And every time without doubt maturity sensors come out to be a lot more accurate when the mix is done appropriately.

Eric Yee:

If I’m let’s say a general contractor, I want to get started using a SmartRock, do I just unbox them and throw them on a rebar? Is there a step I’m missing there in terms of setting them up and getting going?

Sarah McGuire:

Yeah. This definitely happened a lot in the beginning, because, of course, when we came out with our sensors, we were the first company that brought… And really truly right now we’re the only company where you can actually buy sensors, download the application, put them in, and that’s it. A lot of other technologies, you have to invest in the readers and the hardware and the software and things like that. With us, you don’t need to do that.

That created a lot of excitement, but it also created a lot of misunderstanding that someone could put in a magic sensor that would just magically give them the concrete strength. And of course, what we need to do before that is create that baseline that I’ve been speaking of. And to do that, once a contractor has identified what mix they’re going to be using, either they can do it themselves, we’ve had them do this, or they can work with their third party lab, or they can work with their ready-mix company, either way, Giatec team is there to kind of work them through it.

What they have to do is pour 17 cylinders of that concrete, cure them in the same conditions, and then break them over certain periods of time while monitoring the maturity factor in two coinciding cylinders. And as long as those cylinders are cured at the same conditions and the same size, they will all generate the same heat profile and they’re all made from the same mix. They all should be coming to the exact same strength.

Once you were creating that baseline, and I think you’re taking points at day 1, 3, 7, 14, and 28 to create that curve, now we can adjust for that depending on if people are working with ultra high-performance concrete and they want to strip in 48 hours. Well, then we can create a mix that’s a little bit more tailored to getting a lot of results in those early stages to create more accuracy. Those are the things that we work with our clients through, but you do need to take the time to do that. As per the standard, this is something that takes 28 days.

Because if you’re wanting to do a curve for a full 28 days, then you need to be breaking up until that point. If you’re just looking to get results in the first seven days, we can do it in that time. We can also do it at the same time as you’re pouring. We can work with our customers through that, but everything is built into our software. People can do it right on the mobile phone if they want to, but they can also use the dashboard. We have about three or four ways of being able to calculate that really simply. It’s just a very plug and play.

Very different from… We’ve had some of our clients tell us that before they started using our system, they would take maybe 60 to 90 minutes to do one curve. And on our platform, it shouldn’t take you more than 10 minutes.

Eric Yee:

That’s a huge difference.

Sarah McGuire:

Yeah. It’s a huge, huge difference, especially we work with a lot of ready-mix companies as well. Because as I said, contractors can’t just buy the sensors and use them for strength immediately. They have to get that data. We do work with a lot of ready-mix partners across North America. Some internationally as well, but mostly in North America so that they can program their mixes in for their clients. So that if you are a contractor… I’ll give an example.

If you’re a contractor in San Francisco right now, we work with Central Concrete, the U.S. concrete branch out there, they have about 30 to 40 mixes already programmed in there. So if you’re one of their customers, hypothetically, yes, you could grab a box of sensors and go tomorrow because they have that ready to go.

Eric Yee:

That’s interesting. It makes sense to work with those people that have those mixes just on the platform to kind of plug and play almost.

Sarah McGuire:

They’ll also create it in the most trusting way possible. I think that has been one of the biggest hurdles in the last few years is getting people to trust the data coming back, because we’re not talking about software that’s going to help you order groceries faster, although we all love that now because of this pandemic, being able to order groceries to our home is great. We’re talking about understanding what’s happening with the strength of our projects so that we can move on to the next step.

If we are wrong in that estimation, that can cause serious damage, if not be a life-threatening problem. It’s completely understandable for people to want to do all of their due diligence and make sure that this is the right method for them by working with ready-mix companies that know their concrete better than anyone else, that also have a vested interest in wanting to change the way that testing is done. Because oftentimes when it’s done incorrectly, they don’t have much of an influence, but they do get a lot of that blame.

They’re equally as invested in changing this as we are, and they’re going to do it in the most trusting way possible. We’ve taken a lot of steps as a company to do that, not with just the partners that we work with, but even adding the artificial intelligence into our software. By having that as an extra verification tool to know that based on my mix design, the maturity curves that I’m getting are relevant, it’s giving people that extra sense of reliability.

Eric Yee:

I can see where having that extra data and extra reliability makes things just a lot easier for people to kind of sign off on trusting maturity and trusting these sensors. I’ve seen that with some of the efforts that Giatec is doing not just with SmartRock, but some of the other products. There is a potential to have like a sustainable impact on the environment as well. Can you talk a little bit about what that looks like?

Sarah McGuire:

Yeah, definitely. I think we see this a lot with our sensors is I always warn people when they’re about to use the sensors and they’ve never seen maturity data before, and they’ve never really worked with that in a practical way, I warn them that especially if you’re dealing with high heat, if you’re in Louisiana in June, I promise you the strengths that you’re getting from your slab in the ground, they’re going to be a lot higher than you were getting with your cylinders, because it’s just going to generate a higher heat profile.

That’s a fact. If you were to put a sensor in a cylinder and then you put a sensor in a slab in really high heat conditions and you don’t protect the cylinders or anything, you just kind of put them side by side and let nature run its course, your slab is going to break 135-140 degrees Fahrenheit, whereas your cylinders probably won’t get much past a hundred and those will be in their prime curing conditions. We are showing people that their concrete is coming to strength a lot faster than they think it is.

But this is kind of common knowledge among a lot of people in the industry is that people are over-designing mixes, causing them to over-perform just to make sure that they protect themselves. But by over-designing and over-performing in our mixes, we’re usually adding a lot more cement. And by adding more cement, we’re contributing… This is where the carbon footprint aspect comes in.

And if we are able to show people that they don’t need to over-design and over-perform to that extent and they can actually reduce their cement over time, it’s great for their bottom line. Obviously they save a lot of money, which is fantastic. They’re not messing up their schedules in any way, and definitely it has a huge contributor back to the environmental efforts that we’re just seeing a lot more of in our industry.

Eric Yee:

Sarah, for any listeners out there who want to learn more about SmartRock or other Giatec products, what should they do?

Sarah McGuire:

Well, I mean, it’s 2021, so I guess the first thing that they can do is go to our website. Obviously there’s quite a lot of information on there. One thing that I like to redirect people to, our marketing team has done a really great job at putting so many different videos together on our YouTube channels. If you just type in Giatec on YouTube, you’ll find our channel. There’s a lot of really good one to two minute clips in there, so it doesn’t take too much time.

I’ve always found that those are really good way of people just kind of learning a little bit at the beginning. But of course, you can call our company or send us an email. We have a great team here of salespeople, but engineers as well that can talk to you about how it would be applied to your project. But people can request information right through the website or just give us a call and somebody will answer. We have lots of people here.

The company’s sole purpose is just to work with our customers on sensor technology and NDT equipment, so everyone in here is fully trained on how to answer those questions. That’s a great place to start. And depending on where you are in the country, we’ll redirect you to the best place possible. Because like I said, we do have a lot of really fantastic partners out there that are part of revolutionizing the industry with us.

Eric Yee:

Awesome, Sarah. Well, thank you so much for making the time and coming on the show today.

Sarah McGuire:

Yeah, thanks for having me on.

Other Related Episodes

Episode 55 |

February 27, 2025

Optimizing Concrete from Fleet to Finish

In this latest episode, host Sarah McGuire speaks with Chris Wurtz, Division President at Digital Fleet, about the impact of data-driven decision-making in the ready-mix concrete industry. With expertise in fleet tracking technology, Chris sheds light on the challenges and opportunities of controlling what he calls a “factory on wheels”—the mixer truck. He explores the biggest obstacles facing producers today, from data limitations to inefficiencies in delivery, and highlights untapped opportunities to improve performance. Chris also discusses the vision behind Digital Fleet’s partnership with Giatec on MixPilot and how this integration is helping producers gain better control over their operations. Tune in for an insightful conversation on the future of ready-mix operations and how collaboration between technology providers is driving industry-wide transformation. Don’t miss this engaging discussion!

PLAY

Episode 53 |

December 12, 2024

Unlocking AI’s Potential in Construction

In this latest episode, host Sarah McGuire sits down with Sean Devine, Founder and CEO, XBE, to explore the transformative role of AI in the construction industry. With a background in logistics and technology, Sean brings unique insights into the challenges and opportunities surrounding AI adoption in construction. Sean highlights untapped opportunities and discusses how XBE is leading the charge with innovative solutions, including AskConcrete— a groundbreaking answer engine powered by decades of NRMCA data, designed to tackle complex questions about ready-mixed concrete. From identifying industry limitations to exploring what companies need to do to embrace AI effectively, Sean offers a compelling roadmap for innovation. He also shares his journey in founding XBE and his mission to optimize heavy construction operations with cutting-edge technology. Tune in to gain valuable insights into how AI is shaping the future of construction. Don’t miss this enlightening discussion!

PLAY

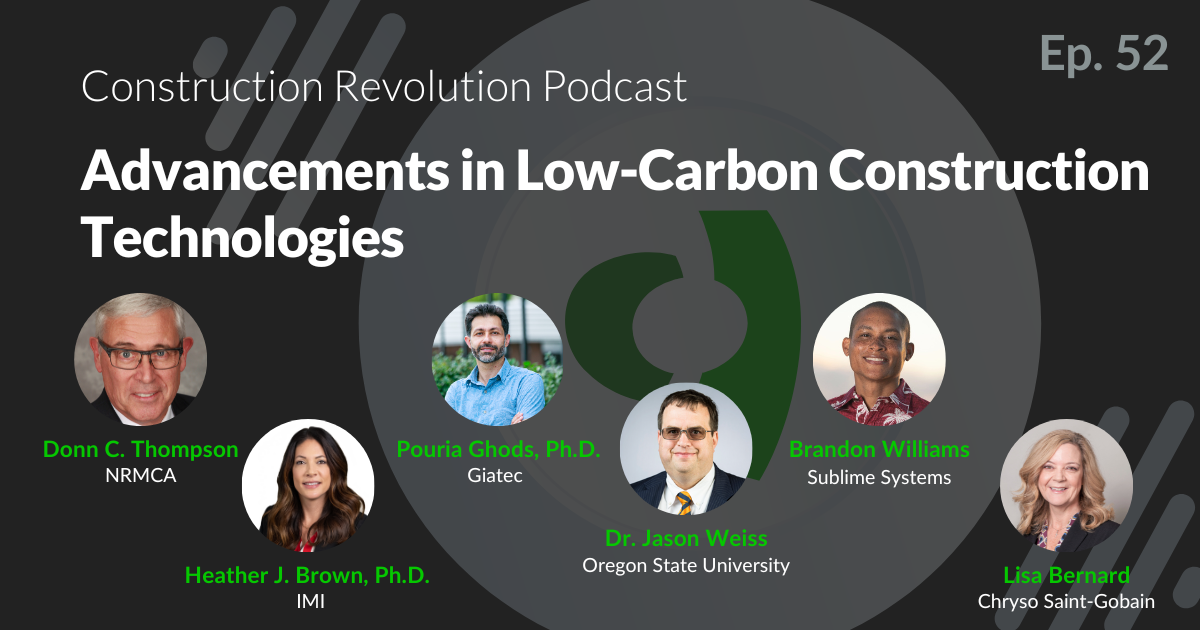

Episode 52 |

November 14, 2024

Advancements in Low-Carbon Construction Technologies

Join us for an engaging and insightful panel discussion from 2024 Net Zero Construction Conference, hosted by Aali Alizadeh, Ph.D., Co-Founder and CTO of Giatec and Technology Chair of The Net Zero Construction Conference. This episode dives into groundbreaking advancements in low-carbon construction technologies, highlighting both the promising opportunities and the significant challenges involved in their industry adoption.

Our distinguished panel of experts features: Professor Jason Weiss from Oregon State University, Heather Brown, Ph.D., Vice President of Quality Control/Quality Assurance at Irving Materials Inc. (IMI), Donn Thompson, Senior Director of Building Innovations at the National Ready Mixed Concrete Association (NRMCA), Brandon Williams, Business Development Manager at Sublime Systems, Lisa Barnard, Sustainability & EPD Program Manager at Chryso Saint-Gobain, and Pouria Ghods, Ph.D., Co-Founder and CEO of Giatec. Together, they offer a wealth of knowledge on the latest advancements in sustainable construction, sharing how innovative materials and solutions are transforming the industry.

Don’t miss this opportunity to learn from industry leaders as they share actionable insights and strategies that can drive meaningful change in the construction landscape.

Want to dive deeper into conversations like the ones in this episode? Join us at the Net Zero Construction Conference 2025 on March 19-20 in the Virbela Metaverse! Experience two days of expert panels, innovative insights, and networking opportunities focused on low-carbon construction technologies. Learn more and get your tickets on the N0CC website!

PLAY

Want to Be a Guest Speaker, Sponsor, or Just Have a Question for Us? Fill In the Form!