Building Better With AI - Episode 8

Episode 46 |

July 11, 2024

The Optimization Journey Has Just Begun

In This Episode

In the eighth and final episode of our "Building Better with AI" mini-series, "The Optimization Journey Has Just Begun," we’re introducing a unique twist. This time, Sarah McGuire, AVP Business Development, switches roles and steps into the hot seat to answer questions rather than ask them. To guide this special conversation, we’ve brought back our Co-Founder and CTO of Giatec, Aali Alizadeh, Ph.D.

This episode provides a comprehensive update on where SmartMix, Giatec’s AI-powered mix management system, currently stands. Sarah and Aali discuss the significant progress made since recording the first episode in December 2023, highlighting the challenges overcome and valuable lessons learned during the implementation of SmartMix.

Listeners will gain insight into customer success stories and the transformative impact SmartMix has had on the concrete industry. This episode offers a reflective and forward-looking perspective on the journey of SmartMix, showcasing how it continues to drive innovation and efficiency.

Tune in for a compelling discussion that not only recaps our journey but also looks ahead to the future of AI in the concrete industry. Don’t miss this insightful and engaging conclusion to our mini-series!

Host

Sarah McGuire, MBA

AVP, Business Development, Giatec Scientific Inc.

Guest

Aali Alizadeh, Ph.D.

CTO & Co-Founder, Giatec Scientific Inc.

Podcast Transcript

Sarah McGuire:

Hello, Concrete Revolutionaries and welcome back to the last and final episode of the Building Better with AI miniseries. I’m your host, Sarah McGuire, and today I am joined once again by Dr. Dr. Aali Alizadeh, Giatec CTO and Co-founder. Aali, thank you so much for coming back.

Dr. Aali Alizadeh:

Well, thanks for having me again, Sarah.

Sarah McGuire:

We’re going to have fun today. Aali and I, had an ideas as we’re wrapping up this series, as we’ve talked about so many different challenges that we’ve experienced in trying to bring optimization to an industry that was not built on a foundation, prepped for that. We’ve talked a lot about cybersecurity issues, change management with the industry, how we’re tackling sustainability, what optimization looks like today, interoperability.

We have some success stories that we wanted to share today, but I asked Aali if he would actually come back and instead of me asking a bunch of our customers questions, I thought it would be an interesting take to have Aali and I discuss all of the challenges and all of the successes that we’ve experienced so far as we are now recording at the end of May in 2024 and we last sat down in December.

So it’s been six months and a lot has changed. So Aali, thanks for agreeing to do this. I look forward to being in the hot seat.

Dr. Aali Alizadeh:

Thanks, Sarah. And it’s a pleasure to host you as the AVP of Business Development at Giatec. You’ve had a lot of experience I think over the past six months with how the industry has evolved in receiving the new technologies and looking at how they can implement software applications such as the SmartMix in their operations. So looking back at our first episode of Building Better with AI, when we recorded this back in December, knowing what you know today what advice would you have given yourself?

Sarah McGuire:

Well, I think I would’ve still given myself the same advice then, but I would’ve really enforced it today, which is to have a lot of patience. I believe in the last episode, we were hypothesizing, we had started to get the product off the ground and we are hypothesizing at the time that the biggest challenge was going to be on the interoperability of things, on plugging our system into a bunch of dispatch systems and other in transit monitoring systems that were not necessarily built with the intention of providing the data needed to spearhead a product like SmartMix that is able to do all these optimizations.

And then even more so, and we were definitely right about that. We were sitting here in December, we had onboarded customers, but they hadn’t fully adopted the product from beginning to end enough for us to realize that although we were integrated into their systems, the integrations were still not providing us what we actually needed to provide that optimal customer experience that we were looking for.

And today, really happy to say that at the beginning of this calendar year, it really felt like we had slowed things down while we were trying to figure out how to solve these problems, whether it was a people problem, whether it was an industry problem, whether it’s a technology problem. And really happy to say that we’ve really felt that we’ve overcome them enough that we are now integrated with every cloud dispatch provider that exists in the North American market, which is extremely exciting.

On top of that, we’ve also created integrations into batch systems and other types of systems that are allowing us to give customers almost the same experience, but it’s good enough considering it’s so advanced from what they were doing. It’s going to be a long, long road for us to actually get to a point where we have this perfect closed loop fashion, but it’s an industry up level that needs to happen. But to be able to say that we accomplished that in six months and now we can take on all of those customers and have that experience, that’s really exciting.

Dr. Aali Alizadeh:

That’s really amazing. I know for construction industry with a life cycle of 25 years on average for technology, this is a very fast evolution of getting something to the market, learning from that experience, its rating, adapting to what customers need in different scenarios. So we’ll be touching on all these experiences and love to hear about your feedback on that as we go through this episode.

But before that, you set yourself with some goals at the beginning of the year and you started going into the market with a SmartMix. What were some of the main challenges that you had to overcome?

Sarah McGuire:

One of the biggest challenges outside of getting the product to where it needed to be, because we did put such a big task as Giatec, we said to ourselves from the get go, we were going to focus on the customers that we could bring on that were set up in a way where we could give them that beautiful experience that we wanted to.

And by doing that, we are openly segmenting a small customer base of 150 ready-mix producers across North America because so many are going through that cloud transformation now. And one of the biggest things that we learned in that is even if a company sets their time aside to program everything that needs to be there, to switch onto systems that they need to, we might be able to provide them more QC functionality with our SmartMix system, but the optimizations will take months to get to a point where they can see something because when you install a new dispatch system and you’re working with that brand new dispatch system, well you’re starting with data from that date that it was turned on.

And optimizations need lots and lots of data and with a couple of customers that we onboarded once they had their new systems put in place and then we plugged in, they go, “Okay, the user experience is great, the interface, I like it very simple. I understand how to use this intuitively, but there’s no optimizations for me because I have no data that dates back two months ago.” And that doesn’t really work with AI. “That’s not enough for us to actually move that needle forward.”

So I’d say that was one of them. But the other one was certainly perception. It has been a huge challenge to bring a product to a market that is focused very much on the quality control department and have people understand that this is going to do 10 times more than what their current quality control systems do today.

SmartMix is a system that they can use as their one-stop shop, but it doesn’t have to be. So then when you tell people that this can be an add-on to their existing quality control system, what does that even mean? And actually trying to explain that value that they can get out of it, that’s what comes with creating a brand new product in an industry that has literally never had something before. The very easy example of that is that 20 years ago, nobody had a smartphone. We didn’t need a smartphone to operate day to day in society, and now we literally can’t imagine our lives without a smartphone. We would be debilitated without it.

We’re trying to create a system that hopefully after many years of use, people can’t imagine their lives without this anymore, that if we unplugged it, they can’t imagine it. But today it’s not supplementing something that is comparable.

Dr. Aali Alizadeh:

Good example. Actually, back in the day with the landline, people had smartphones and then they realized they don’t need landlines anymore. And I remember back in the day I had both. So why am I keeping still a landline? With that analogy, do you look at QC being replaced with a new category of software? Do you think this new category of software, and feel free to define what this new category is, is it going to be complimentary to the existing QC systems? How do you look at the SmartMix as a new category product versus industry standard QC systems that are available today?

Sarah McGuire:

Well, I’m going to speak in very general terms because I think we’ve also been really fortunate. In the past we worked with 20 plus companies that were on our AI council that really helped us develop this. And those AI council members, I would say we were very fortunate to be around a bunch of companies that really saw the importance of investing in their quality control department and therefore we got to deal with very elite minds in that.

So I want to be careful about how I generalize because the next thing that I say is very contradictory to that. One of the biggest things that we’ve experienced is that going into most companies, if people haven’t actively invested in their quality control department as part of their advantage, then we’re seeing that they truly have no idea what their QC people are doing day to day.

And those are the people that are responsible for managing the highest cost of their business, which is their materials. And a lot of them will come back and say, “I don’t know what Bob does all day. For all I know he could be sitting there playing solitaire.” Well, you go and spend a day with Bob and Bob is putting out fire, after fire, after fire.

And so what we’ve noticed among the general population is that most companies, they’re using their quality control systems or they’re working on something customer spreadsheets or sometimes they’re sitting with things that are in folders, but they’re mostly looking at it as more of the QC department is enabling the sales team to be able to bid. They’re helping putting out fires, they’re troubleshooting things that come up, but they don’t look at their quality control systems as a way that they can maximize their profit margins or maximize their time.

It’s a lot of compliance when they have to troubleshoot an issue, that’s where they might end up going. They pull up the break reports that they need to investigate an issue. But sometimes what we’ve noticed with some companies is they barely have any data in their spreadsheets. They’ve only put it in there if they felt that they were going to need to troubleshoot something after. So even when we’re trying to compile all of this data into our system, it’s a bit of a hunt. We have to go and find this data in all of these project folders that exist.

And then when you put it in there, they realize themselves how little data they’ve actually had to work with because if there wasn’t an issue, they didn’t go after it. So I would say as a general whole, quality control departments have looked at their systems, whatever they’ve chosen, whether it’s an out-of-the box QC system, whether it’s a custom thing that they’ve built, that’s the most amazing spreadsheet you’ve ever seen in your life that only this one person in the whole company knows how to use, but they’re looking at this for compliance.

And they’re not looking at QC as something that can be a proactive QC role. They’re looking at it as a reactive QC. But I think another really interesting point is that in the last reports that were done back in October, it was noted that in North America there are only 750 QC experts in the country.

Now, I don’t remember the statistic specifically on what they defined as an expert, but I believe it has to do with certification of some sort. 750 across 400,000 cubic yards of concrete means that you have less than one for every 400,000 cubic yards. Well, the average ready-mix producer does 250,000. So you’re telling me that we have less QC professionals for each ready-mix producer that exists, and that’s a huge disparity that we have.

The other misconception that then we have is people think that because we’ve built something that technically it does do core QC functionality, we have the submittals, you can manage your mixed designs, you can do everything that you’re doing in a standard QC system, but it doesn’t have all of this AI and insights that come to you automatically.

Well, the other problem then that we’ve had is people say, “I can’t find a QC person, so I’m going to replace it with this software.” That does not work either because this is a system that is bridging the gap on a lot of that manual tedious work that would otherwise either be done very much by hand. That’s what a lot of companies say to us is, “Wow, you’ve been able to generate what a curve would look like with this mix if I took out 10 pounds of cement tomorrow, you were able to do that with a click of a button. It took me a couple of hours to do that, or an hour to do that.” Or a submittal that now you can generate in a click of a button. “It used to take me so long to be able to do that.”

So we’re getting rid of some of that mundane stuff so that they can spend more time on the impactful stuff. Well, if you don’t have somebody that is knowledgeable enough or that you’re not willing to invest to create that knowledge, we can bridge the gap for a new QC professional to come in, do some of that easier stuff for them so that they can spend time on the exciting stuff. But you’re still going to need somebody to sit there and leverage it because Giatec is not going to manage your QC remotely from Ottawa and Canada. It’s something that still needs to be leveraged by these companies.

Dr. Aali Alizadeh:

And actually on that point, this came intuitively to us as a no-brainer aspect of having a cloud-based software application that brings data from all these stages of concrete production from batching, dispatch, performance data in one place. And you mentioned, and our customers are looking at this and say, “Wow, this is amazing. I can see everything in one place and I can be very proactive. I can connect dots together much faster, much easier, and make decisions more quickly.”

Is that how you thought SmartMix would evolve over time? Initially there was one value proposition that you started a SmartMix with, but you realize there are other value propositions that customers are pointing at without us really realizing those are really strong value propositions.

Sarah McGuire:

That’s a really good question. If we go back to two years ago even, when we first came out with SmartMix, it was an optimization platform and that was it. And our hope was to be able to plug this into other systems and generate these optimizations for people to see and take. When you go and do that and you’re looking for systems to latch onto and they don’t exist in the way that you need them to, well then the product had to evolve.

But we still very much were showing this is an optimization platform. Industry averages tell us that over design is happening at a rate of 20 to 30% across the board. Our data will tell you that it’s even a little bit more than that, especially because we’ve worked with so many companies that didn’t have a QC system today as a starting point.

So when they plug everything in right away, they see so much more. But certainly that over design is a big part. Well, optimizing isn’t just cutting, it’s also reducing your risk. So we see a lot of examples where people need to actually de-risk their mixes, and we’re not actually helping them get leaner, but hopefully we’re helping them prevent a big catastrophic event in the future.

Another one that we have seen, to your point, is that actually having a one-stop place where in one single platform you now have everything that you need, forget about optimization for a second, let’s talk about when a low break comes back or a rejected load because of slump. If you have all of that data now sitting in your database and you can see exactly where it all came from without having to go from screen, to screen, to screen and then contacting multiple different departments because you need access to their systems just to troubleshoot one tiny thing that is a huge game changer as well.

And it’s interesting because a lot of people would say, “Oh, with your system you can see exactly how much money you’re saving based on how much you’re optimizing.” But it’s become so much more than that because we have some companies that have started using our system, they’ve barely done any optimizations because of all the red tape that they need to go through, but yet they’ve gotten so much value from having everything in one place or just a place where they can put all of their performance data where they’re actually going to generate insights that give them something in return.

And that’s been a big shocking moment to us as well, is that there’s a lot of things that people are getting from the system that they know innately exist, but until they see it in one place, they cannot act on it.

Dr. Aali Alizadeh:

And I know it’s been a relatively short period over the past six months and maybe actually since you started working with the early adopters, and we’ll talk about that in a minute. But do you see that the market perception is changing or shifting the way that customers, concrete producers in particular, are looking at software applications such as a SmartMix? Has it been shifting over the past few months as do you think we’re still at the beginning of that shift? How do you look at it?

Sarah McGuire:

I think if we try to bucket the whole industry together, we’re probably still very much at the beginning of that. We have, again, been very fortunate to work with a lot of thought leading type of companies that see this and they learn how to latch onto it. But getting to a point where we can actually make general statements about what people will get from this system, we’re still very new to. Every company that we have onboarded, we go through a very intense vetting process to really figure out what systems they’re using, what their day-to-day operations look like, biggest challenges that they have, where does their data live today, et cetera, it goes on.

And based on that, every company is going to get a bit different recommendations in terms of what they’re going to be able to get out of the system in the first month, three months, even year. I think especially in these prescriptive markets that we have, we’re seeing a lot of opportunity there. But at the same time, there’s a lot of reasons why companies can’t just enact an opportunity to optimize tomorrow.

It’s a whole process that they need to go through and then it also needs to be a big enough opportunity for it to be worth it. And so we’re even seeing that we’re adjusting things in our product or we’re adjusting things in our onboarding to kind of guide them down that path to success a little bit easier. But I would say we’re very much at the beginning of showing the industry that this is worth their time.

Dr. Aali Alizadeh:

So let’s expand on that as we’re obviously going into the market with the early adopters and the new cohort of customers, I think you set yourself with a goal of working with early adopter concrete producers, some in the US, some in Canada, small producers, large producers. And I think the success was way beyond our expectations. The goals that we set ourselves with at the beginning with these early adopters we met and exceeded those goals and expectations.

So I would like to actually ask some questions on that area and what made that early adopter program so successful? So can you maybe start with onboarding process for a concrete producer who has not used software applications such as a SmartMix, let alone maybe QC systems, and how does that onboarding process look like?

Sarah McGuire:

That’s a great question. So yes, you’re right. We did exceed our goals and I would say a big part of doing that is also setting the expectations of the customers early on. Do not over promise what can be done. Obviously AI is very buzzy right now and we want to make sure that the expectations are set for what they’re going to get out of it, and so I think that was really key to making all of our early adopters really happy and then contributing to the success of now our next cohort of customers that are working with us now.

When it comes to the onboarding process, it took in the beginning probably about six to eight weeks for us to get all of that data in the system. We had integrated the systems, we saw the optimization starting to build, but we didn’t realize that when you’re integrating into a dispatch system… I guess we probably realized it, but we definitely understood it better that when you’re integrating in with a dispatch system and all of these companies were using their dispatch system as their main source of mixed design information because they didn’t have out of the box QC systems today.

Well, then you’re plugging into a system where you’re trying to do way more with that information than has ever been before possible. So you realize you’re just missing variables and information that exists. One of the funny things was that our cloud dispatch systems companies are not actually saying where their cement supply is coming from or what type of cement it is. Why? Because it’s in their brains. They maybe only have one or two suppliers. We had one company that has five different suppliers where they had it very specifically laid out. But the other ones, they just know what’s in their mail that day. So they don’t need that information for what they’re doing day to day.

Well, when you’re swapping cement suppliers and you’re trying to optimize a mix and show what the performance is for each mix with different cement supply, yeah, that’s extremely important. So just little things like that that became really evident during that onboarding process, which what has caused us to do is extremely refined that vetting process now.

So by the time today… Thank you to all of our early adopters for going through that pain with us, it took a couple of months. It didn’t help that we were also doing it in the Thanksgiving American holiday time period, so we did get a lot of benefit from that. But now when people go through onboarding, we’ve done all of that vetting before. We’ve integrated… we have our checklist of what needs to come through. Even before agreeing to work with them we go through a couple of extreme vetting processes as well.

So that once again, we’re just setting their expectations. If you have a great QC system today where you’re putting everything in really solidly and we could just pull from your existing QC system and start optimizing tomorrow, that’s incredible. We can start doing big things with that right away, and we can also figure out what your testing frequency is and all of these other important variables to know exactly what you should expect. If you’re a company that’s working with Excel sheets and a lot of PDFs and folders that you’re only checking if a problem comes up, well, those are companies where it’s going to take us a couple of months probably to get everything into a place where we can bring you to a nice screen and you actually get something out of it.

And so it’s just, I wouldn’t say the onboarding process necessarily has changed that much because now we’ve just taken what we thought was going to be easier in the onboarding process, we’ve taken it into the vetting process so that the onboarding is smooth sailing and people are ready to fly.

Dr. Aali Alizadeh:

So the new producers who are joining the SmartMix software cohort, they are going through that onboarding much faster from what you’re saying.

Sarah McGuire:

Yes, where before we commit to an onboarding date, we’ve gone through all of that. I’ve learned a heck of a lot about some of these systems myself, so I can even vet them myself without having to involve our product team. So we’ve just made that process a lot smoother because we know what barriers we can experience, so we know how to either set the expectation that they’re going to come up and make that part of the onboarding plan or we can make sure that they don’t happen at all. So we’ve become a lot more refined in that.

Dr. Aali Alizadeh:

What were some of the biggest challenges that maybe you had foreseen or not foreseen and you had to add and potentially turn that into a success at the end of the day?

Sarah McGuire:

Right. So we had foreseen the nature of the prescriptive markets in the US and I think prescriptive mixes, it’s a spectrum. Some of them it’s just a cement minimum, a water to cement, and then everything else is you can do what you want. Others are really, really refined and quite intense. So the system that we built SmartMix allows for these real time adjustments.

Which was very simple for our Canadian companies to latch onto because they have more flexibility in the vast majority of their mixes. On the American side, we see a lot of opportunities that they can optimize, but it’s not as simple as, “Just because SmartMix makes allows me to push back to my batching system doesn’t mean I can just do that tomorrow.”

We would see a lot of barriers and it might be submittals that have already been put forward, therefore we’d have to go through a resubmission process which can be done, or it could be as much as this project, absolutely this is the requirement, and even though you’re showing 25% over design and I could absolutely confidently do this, there’s just no way that I’m actually allowed to do it.

Sometimes we would just even hear that our QC users would look at it and go, “Oh, that’s a very easy one, but I’m going to need to call my sales guy because I need to make sure that the customer doesn’t get worried when they see a dip in strength even though it’s nothing for them to be concerned about.” So there’s a variety of reasons why people can’t just take an optimization and use it tomorrow.

And we did know that, but now going through the process of helping them realize it, that’s going to be a bigger challenge and it’s going to be extremely subjective. We can certainly see in the future how the more data that we accumulate, perhaps we can start really working with the industry to move that forward in a bigger way.

But right now we want our companies to get early benefits from this. We want them to go after the low hanging fruit. So then when we’re working again with those American customers that they say, “Okay, these mixes are prescriptive. I want to focus on these ones, I know I can make changes.” Well guess what? Nine times out of 10, those are the mixes they don’t have data for. Because sure enough, they’re not going after a lot of data for mixes that nobody’s bothering about. Of course, they’re not especially these companies that didn’t have an out of the box QC system or were literally managing three times as much concrete as the industry average with one person like I had mentioned before.

So then it’s using the system to actually use our predictive capabilities to say, “Okay, based on your high volume mixes that you do have control over, thankfully with artificial intelligence, we can actually model what those are probably doing.” And then now they have a direction of testing that they can go and invalidate, and we’re seeing huge money results from those because these are mixes that they can change, but were not in their peripheral before because it wasn’t worth their time, they weren’t going to bother.

But now that we’re able to put it all in front of them and make it really seamless for them to just say, “I’m going to target this.” And two weeks later they come back and say, “Yes, let’s make that optimization.” That’s huge money that was just not even in their view before.

Dr. Aali Alizadeh:

So can you maybe actually walk us through that experience? Because some producers may think, “Okay, to optimize my mix designs, even with a SmartMix, I have to test my materials and upload test reports and send my samples to a lab somewhere and then analyze the graphs and things like that and then look at it and say, do I want to optimize it? And then upload my new mix design on the system.” Can you walk us through that process for SmartMix and how simple that is for concrete producers to experience?

Sarah McGuire:

Yes, absolutely. And I think that’s a very interesting one to dive into because a lot of the time when we’ve been speaking to newer customers that are looking to get on our system, their initial reaction is typically, “Well, I’m pretty dialed into my high volume mixes.” And that makes sense, of course they would be. These are their biggest money makers in the company. You have a QC person that sits there, and they don’t sit there all day, they do a heck of a lot of work.

But their main job is to manage their materials, they’re putting out fires, but ultimately they’re probably spending the majority of their free time that they have working on their top five to 10 mixes and making sure that they’re always dialed in. The process that you just described it’s a very tedious process to go through all of the testing and to go through that modeling and the calculations, and a lot of them have been doing it by hand.

Some of them are doing it in their systems, but a lot of the time what we saw when they’re going into their systems is they put the data in there, they get a certain way, and then they export and they keep working on their Excel sheet because it does what they need it to do better on the Excel sheet or more intuitive for them.

What we’ve seen is that when we plug SmartMix in, we’re not necessarily seeing a lot of movement on their high volume. I’m not saying no movement, but not a lot. They might be able to shave a couple bucks off here and there every time they do an optimization. Sometimes we even see one of the big ones that we saw was a 50 cent per yard change, but it was across their second-highest volume mix that was going to be tens of thousands of dollars in savings and they might be able to get another incremental change in the future. So those high volume ones, even if you can do something small, it’s still worth it.

But where we’re seeing the bigger value is actually across all of their really low volume mixes or unique mixes that they do have all of this data on, but because they’re not high volume enough, they’re not dialed in because of the process that you just described. It’s a very tedious manual process regardless of what system that you’re working on. So it’s not really incentivizing to do it on these smaller mixes.

Well, one of the companies that we work with, they’ve done a couple of their big optimizations. They have 70 different opportunities to now look at in their system today across 70 different mixes that could equate to over $300,000 worth of savings. Five high volume mixes with the small change gives you 300,000.

But then all of a sudden when you have all of these mixes where you can go into SmartMix, it calculates automatically, “Here’s what your reduction would be. Here’s the changes to all of your properties. Right on one screen for you, you can see the reduction in cement by pounds or kilograms. You can see the reduction in CO2 value. Anything on the water to cement will be called to your attention right away. It’ll show up in red.”

Dr. Aali Alizadeh:

What would a producer using a SmartMix see, when they log into the system?

Sarah McGuire:

They immediately see every single mix that they have. Now, of course, you can do it by date range, but every single mix that has been batch produced, and if we have enough test data on it, they’ll immediately see insights for them to start incrementally adjusting today. And so they can review all of these in seconds because we have it all in one place where we’re not just showing you what has happened, but we’re showing you, “If you took this change, here’s all the proportions that would change. Here’s the curve that you would see.” And then we’re allowing you to push it right then and there.

Dr. Aali Alizadeh:

That’s a big value proposition for customers who are producing thousands of mixes every year, and to be able to see every small adjustment possible in one place, automatically and push out from SmartMix to their batch and dispatch systems automatically, that’s a huge, huge time saving.

And obviously this is built on the backbone of Roxi, the most comprehensive, strongest AI algorithm built for the concrete industry train, I think more than 200,000 mixed designs. How do you build trust within the customer base to say, “Okay, there is a suggestion, there is an optimization shown in my dashboard.” How can I trust that optimization is delivering the performance that it’s predicting?

Sarah McGuire:

Right. No, it’s a great question. I will answer that question, but first I’m going to tell you a story of one of the customers that we did onboard. They’re an innovator, absolutely. They saw the value of this, very excited about it, and we were going through their system. So this is a company that has already bought into the vision, they see the value right away. They’re paying us money today to be able to use this system so that they can explore these optimizations.

And yet still we go through one by one every question that they ask, “Well, what would happen to the AG if you do this? What would happen… Have you reeled? What’s the effect on the water to cement? How much water is actually going to go there? What’s going to be the effect on my ad mix?” Asking every possible question. Well, our system had the answer to every question that they had.

So when you ask me how to build trust, well, it’s about making sure that everything is there, that every scenario they can actually play around with and start to use. It’s also about making those adjustments incremental enough that half the time, a lot of the adjustments that we’re showing that they can do, many of them knew that they probably could, but now they have all of the data.

So now they say, “Okay, I can see this outlier was here. I can see exactly what would happen if I make this change.” And that kind of creates that trust. If we’re showing them an optimization that they’ve never seen before that they didn’t know actually existed, that takes longer. And so that’s what happened with this customer was we were showing them an opportunity, but they had to reduce the amount of water that was going into this mix.

Not by a lot, but it was the least water that they would ever have batched with in their life. And the response back after we went through every single question they had and we were able to show them on the system was, “Listen, this looks like a very valid optimization. I’d love to cut this out today. But I’ve never sent concrete with less than this amount of water. It must be something that’s different in our materials that doesn’t exist anywhere else.” And everybody on the call was just quiet.

And I was really glad that our team got a chance to experience that feeling of, “But we’ve always done it this way,” because even when you have truly answered every question in the book possible that customers still went on to trial batch even though it was such a small change that it didn’t seem like it was really necessary, but it wasn’t an optimization that they expected to see. So it just takes time.

Dr. Aali Alizadeh:

So that’s actually an interesting point. And from a product perspective, this would’ve not been possible without the bit that we had on being cloud first, having everything on the cloud, having everything connected in real time, all the systems together so that we can get that data flown into the SmartMix in real time and make those adjustments continuously, essentially every load could be a new mix design depending on the raw material properties or the performances required in job site and weather changes and things like that.

So it’s a big bold move from the SmartMix perspective and from interoperability today, not many integration partners are fully on the cloud. So how do you see the industry evolving towards a state where we will have every piece of data on the cloud making it possible for every producer to do these real-time optimizations?

Sarah McGuire:

I can say that from the perspective of the person that’s trying to bring this out to the market that is working directly with customers, when I have a company that is super excited about what we’re doing, they see the immediate value, but then we look at their entire architecture and there’s just no entry point whatsoever that we can integrate with simply, it’s really disappointing.

Because these companies want it, they’re ready for it, but then we don’t have something that we can bring to them that makes it simple. These days now that we’ve gotten to a point where we’ve done our seamless integration, so if you’re on a cloud-based dispatch today, nine times out of 10, we can plug in, you can start seeing your data tomorrow and you can start working with the system right away, which means it’s a very hassle-free experience.

Whereas companies that aren’t set up like that today, and if they’re not considering any transition whatsoever at this point, we’re not ruling anyone out anymore, but we’re just going to be very candid with you about the experience that you’re going to get.

And so once again, we’re going to manage those expectations to make sure that you know what to see or what you’re going to see when all of that data eventually does get in there. And unfortunately in setups like that, we’ll have to charge for that because it’s going to take manual work. So it can be frustrating on that side.

However, the whole industry is getting there. We built a product based on only 10% of the market being able to use it today, and we know that, but these systems take a long time as well to understand how to use them. And so we’re willing to work with the industry so that when they’re going through their transformation to the cloud, they now have the advantage that other companies didn’t. They know that they want to use optimization.

So when they go and they program their dispatch system to have all of that data in there that is needed so that they can plug in, there will be less hurdles that we overcome because they built it with that purpose. So on one hand, yes, we can’t plug you in today, but on the other hand, you are now able to learn from the past experience that we’ve had of companies that have been on cloud dispatch for half a decade, over a decade, that didn’t have the system set up, and we had to go through that work with them. So you might be coming from a different vantage point than others. It’s just I guess all how you look at it.

Dr. Aali Alizadeh:

I think that’s in a way building for where the industry would go. So you don’t want to build a technology, especially on the high end, cutting edge technologies on what the industry status is today. So the industry is evolving really fast. The digital transformation is happening in our industry, and over the next few years we see more and more concrete producers on the cloud because their work will become more efficient. And building a SmartMix for that estate is what Giatec is betting on essentially, right?

Sarah McGuire:

Right. We’ve always done that. Even with the other technologies that we had in the past, for example, even with sensors, we were this similar situation that although maturity sensors were known in the industry, they were seen for only very specific use cases in the past. So then we brought them to the market, and we’re not trying to compete necessarily with other maturity providers. We’re trying to compete with the old way of doing break tests that when you go to somebody and you say, “How often do you get a low break?” And they go, “Oh, you know what happens at this frequency rate? But that’s normal and we’re used to it.”

But you don’t need to be used to that. And we have to convince people that there’s a problem that exists before they’re even willing to look at a solution. And that’s very much the state that we’re in. I think the big thing that’s really driving this as well is profit margins are decreasing as material costs are getting higher.

We’re seeing across the industry that people are concerned about fly ash shortage, they’re concerned about sand shortage, they’re changing in cements the sustainability requirements that are coming in. These are all things that they’re going to have to start accounting for. And if they have to sit there and hand model every single one of these mixed designs without the power of AI, they can do it so much faster if they just use the technology that’s available to them to make that impact and move faster.

This is their competitive advantage and I think people are starting to see that, but we definitely have a lot more education to go that optimizing is a lot more than just reducing cement today. There’s so much unpredictability that’s going to be on the horizon that if you just use AI to get to the answer faster, we can be more productive.

Dr. Aali Alizadeh:

Of course, of course. And looking at the future, and obviously you’ve got to experience how the industry is reacting to some of the advanced technologies such as AI today. Where do you see our industry, in particular ready-mix industries, heading over the next decade?

Sarah McGuire:

For us as it pertains to optimization, what we are seeing is that when we plug our system in, people are able to get a lot of low hanging fruit, but then they have lots more that needs to be done. And it’s not just by looking in our system, they have to test different mixes. They have to get data that didn’t exist before. They have to start monitoring that data.

But a lot of people have also said to us, “We don’t know. Once you optimize how much further can you go?” Well, here’s the other shifts that are happening in the industry. For example, if you’re working with batching software that becomes more accurate, the design that you’ve created in a SmartMix system that you’ve optimized now becomes more accurate when it’s being batched. Well then what about everything that happens when it’s in transit? Now, if you’re not optimizing that process, what’s the point of optimizing the mix? Everything needs to kind of work in a closed looped way.

And I think what we’ve seen is that SmartMix actually helps you identify some of those gaps that may be, “Yeah, we can help you move the needle a little bit here, but without optimizing the other parts of your workflow, we can’t touch it anymore.” And so now you’re going to be optimizing that part, and we’re just going to see that the ecosystem is getting stronger and stronger, but it’s going to take a long time before we can get all of the data in the right places.

Not even just the data that exists today, but a big factor that we hear about a lot is, are you measuring workability? I love this question because, Aali, who is measuring workability today? Nobody, there’s no factor. There’s no real scale. We tried to identify a scale that’s super subjective in SmartMix so that people can give Roxi a little bit of feedback, but at the end of the day, aside from slump, there really is no workability testing.

So how can you create an algorithm for something that doesn’t exist today even with data? If you have the data, you can code an algorithm pretty simply. Sorry, to our software developers, I know it’s more complicated than that. But once the data is there, you can kind of work with anything that you have.

But ultimately we’re going to start identifying different places that we can now continue moving the industry forward that weren’t in our peripheral before because we’re so caught up in these mundane tasks. And I think this concept of technology coming in, replacing people, we can barely find them. Everybody complains about not being able to find people. I get calls from companies on a regular basis asking if I know any QC managers that are available, and I almost want to laugh and say, “I can monitor your QC remotely at this rate,” because I basically feel like we are doing that for some companies because it’s just so hard to find them.

Then you have the driver shortage that is happening because we’re trying to find super expert concrete ready-mix drivers, and we’re expecting so much of them. But if we can lessen how much they need to do, or bridge that gap, or bring some of that mundane stuff to them, maybe we can make it easier.

So in terms of where I see the industry going, I mean selfishly I’m going to say we’re going to see a lot of those advancements make SmartMix bigger and stronger, but we just need in general to do an industry uplift and we all need to be sharing this back to the industry on best practices that need to happen in order for us to keep evolving.

Dr. Aali Alizadeh:

And actually, you mentioned something very interesting that there’s so much optimization you cannot remove the whole cement content from. So there is a bottom cap that you can go to without compromising on the performance. So to achieve higher optimizations, it’s not just about the mix itself, it’s looking at the in transit, looking at the job site, and not all of this can be added with software alone, right? So what do you see is the role of sensors to get real time data back to a software application for optimization purposes?

Sarah McGuire:

So the role of sensors is interesting because there’s a twofold where my brain goes, obviously the selfish brain is going to tell you that institute testing of concrete is key because that’s going to give you the real value of what’s actually happening in your mix. If we are optimizing based on lab performance cylinders, we’re barely going to move the needle at all. If we’re doing field, that can help us a little bit, but who cured them?

So then if we can get into sensors and then we have maturity sensors and now our new self calibrating sensors that also give you that real true concrete strength, but it’s not standardized, and that’s another thing that we need to work as an industry to get more recognition around that. So that actual curing process is huge, but there’s a whole other process that happens in the making of concrete from the time it leaves the plant to the time that it gets to the job site.

And SmartMix is begging for that data. We need that data. We need visibility into that black box on wheels that we call it that kind of factory on wheels. There’s so much that’s happening in that process that if we can even just monitor it, let alone control it in real time, now we’re starting to get somewhere. Because if you are looking at your mix after the fact, you can optimize, but it’s only going to get you so far. If you can actually start taking decisions in real time, in this reactive nature of an industry that we’re already in, that’s going to be a game changer.

Dr. Aali Alizadeh:

Awesome. And on the software side, based on the feedback from early adopters and also the new cohort of SmartMix users, you have developed a roadmap ahead of you. We’re just scratching the surface on what is SmartMix can do today. Is there anything you can share about the upcoming exciting stuff that SmartMix is going to deliver to the concrete industry?

Sarah McGuire:

Yes, absolutely we can. And I think I’ve touched on this a little bit before, that we’re seeing so much opportunity in the system right now, but it’s how we can enable people to take that opportunity really easily in a system. We’ve made it intuitive, but there’s other factors now and approvals and things like this. So there’s going to be more coming in that regard.

One of the back and forths that we had for over a year before we finally made the commitment to do it was whether or not we should build quality control features or not. As a company, we don’t want people to look at us as just their QC system. We didn’t set out to build a QC system. If you’re looking for one today, there are great options out there that can do that for you.

However, based on the demand from people to see everything in one place, we have now built what we believe are those core QC features. And over the coming months, we’ll have companies that are using us just the way that they’re using standard QC systems today in a lot of cases.

That said, companies that want to stick with their system today and integrate with ours, we can do it all. We ultimately don’t really care how you’re using our system as long as you’re getting that optimization value and what that AI is doing. But we completely understand the call to have everything in one place and one stop because it does make things simpler.

But it’s all about making sure that the functionality enables people to actually take the suggestions and do something with them. And we are starting to put a huge focus on that.

Dr. Aali Alizadeh:

Thank you for sharing that, Sarah. I think we cannot wait to see what SmartMix will bring to the market over the next year and beyond.

Sarah McGuire:

Maybe we’ll do an update then, maybe we’ll come back and say, “Okay, where did we end up? Oh yeah, SmartMix looks completely different now.”

Dr. Aali Alizadeh:

So as we conclude this miniseries, what final thoughts or message would you like to share with our listeners on the role of AI for building better?

Sarah McGuire:

The message that I want to share is not to be scared of AI. Even myself, I’m not the most tech-savvy person, which is quite ironic given what I’m doing. But I also have my hesitations towards how this can be used. And I would say that our biggest enemy is ourselves and not giving things a try in a very low risk way.

Anyone right now that has never used ChatGBT for literally anything, just ask somebody how it can be used or leveraged for anything. And you’ll see that it doesn’t need to be as scary as it needs to be. And in a world that is evolving in all other places, the pressure is on for us to keep up.

And leveraging AI is absolutely something that we need to do, but we need to do it right, and the industry needs to come together to be able to figure out what those right paths are. And so that would be the message that I would leave.

Dr. Aali Alizadeh:

That’s a very good message. And I think from our experience, I know actually people who didn’t believe in software in our industry, and now there are avid AI users, that’s a big leap forward for them. And it shows how AI is getting integrated with our day-to-day operations and use of different products. And the advancements are so fast, and with announcements such as what OpenAI is doing every month, every quarter, we see this evolution is happening so fast.

So this is very exciting and our industry is going to benefit immensely from that advancement as well. Thank you for putting this together. Again, I think our audience would definitely enjoy listening to all the experts that were invited to talk about Building Better with AI from different perspectives, and we’re looking forward to the next miniseries.

Sarah McGuire:

Thank you, Aali, for joining. Thank you for flipping the script back on us. This was different to be in the hot seat. I now have empathy for my other guests.

Dr. Aali Alizadeh:

Thank you.

Other Related Episodes

Episode 55 |

February 27, 2025

Optimizing Concrete from Fleet to Finish

In this latest episode, host Sarah McGuire speaks with Chris Wurtz, Division President at Digital Fleet, about the impact of data-driven decision-making in the ready-mix concrete industry. With expertise in fleet tracking technology, Chris sheds light on the challenges and opportunities of controlling what he calls a “factory on wheels”—the mixer truck. He explores the biggest obstacles facing producers today, from data limitations to inefficiencies in delivery, and highlights untapped opportunities to improve performance. Chris also discusses the vision behind Digital Fleet’s partnership with Giatec on MixPilot and how this integration is helping producers gain better control over their operations. Tune in for an insightful conversation on the future of ready-mix operations and how collaboration between technology providers is driving industry-wide transformation. Don’t miss this engaging discussion!

PLAY

Episode 53 |

December 12, 2024

Unlocking AI’s Potential in Construction

In this latest episode, host Sarah McGuire sits down with Sean Devine, Founder and CEO, XBE, to explore the transformative role of AI in the construction industry. With a background in logistics and technology, Sean brings unique insights into the challenges and opportunities surrounding AI adoption in construction. Sean highlights untapped opportunities and discusses how XBE is leading the charge with innovative solutions, including AskConcrete— a groundbreaking answer engine powered by decades of NRMCA data, designed to tackle complex questions about ready-mixed concrete. From identifying industry limitations to exploring what companies need to do to embrace AI effectively, Sean offers a compelling roadmap for innovation. He also shares his journey in founding XBE and his mission to optimize heavy construction operations with cutting-edge technology. Tune in to gain valuable insights into how AI is shaping the future of construction. Don’t miss this enlightening discussion!

PLAY

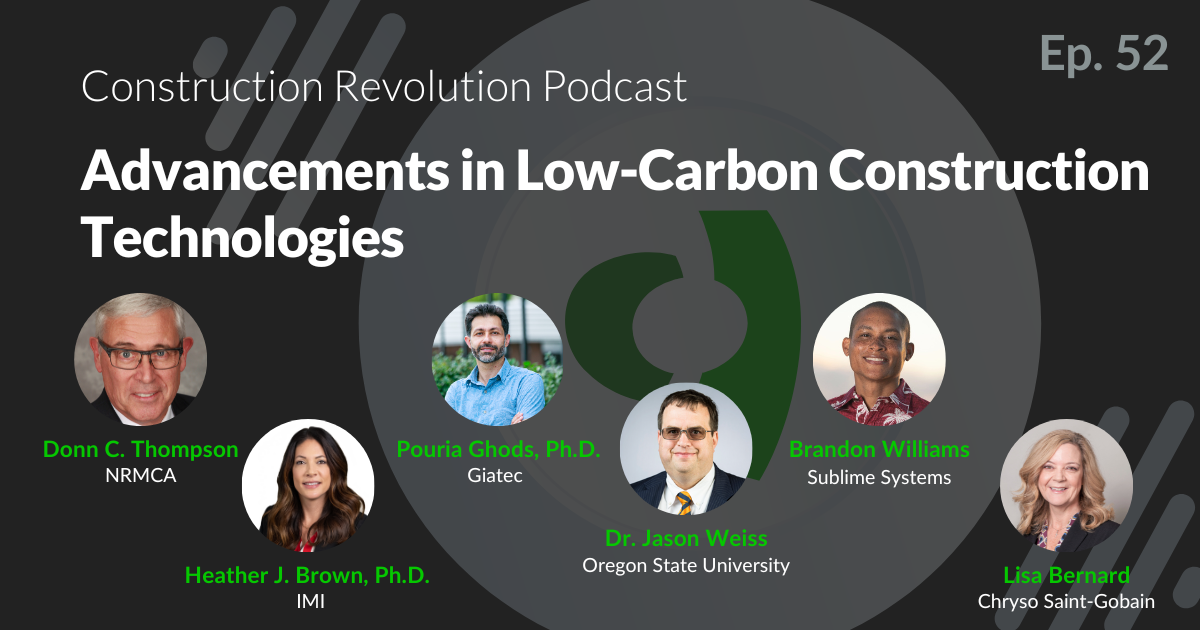

Episode 52 |

November 14, 2024

Advancements in Low-Carbon Construction Technologies

Join us for an engaging and insightful panel discussion from 2024 Net Zero Construction Conference, hosted by Aali Alizadeh, Ph.D., Co-Founder and CTO of Giatec and Technology Chair of The Net Zero Construction Conference. This episode dives into groundbreaking advancements in low-carbon construction technologies, highlighting both the promising opportunities and the significant challenges involved in their industry adoption.

Our distinguished panel of experts features: Professor Jason Weiss from Oregon State University, Heather Brown, Ph.D., Vice President of Quality Control/Quality Assurance at Irving Materials Inc. (IMI), Donn Thompson, Senior Director of Building Innovations at the National Ready Mixed Concrete Association (NRMCA), Brandon Williams, Business Development Manager at Sublime Systems, Lisa Barnard, Sustainability & EPD Program Manager at Chryso Saint-Gobain, and Pouria Ghods, Ph.D., Co-Founder and CEO of Giatec. Together, they offer a wealth of knowledge on the latest advancements in sustainable construction, sharing how innovative materials and solutions are transforming the industry.

Don’t miss this opportunity to learn from industry leaders as they share actionable insights and strategies that can drive meaningful change in the construction landscape.

Want to dive deeper into conversations like the ones in this episode? Join us at the Net Zero Construction Conference 2025 on March 19-20 in the Virbela Metaverse! Experience two days of expert panels, innovative insights, and networking opportunities focused on low-carbon construction technologies. Learn more and get your tickets on the N0CC website!

PLAY

Want to Be a Guest Speaker, Sponsor, or Just Have a Question for Us? Fill In the Form!