The American Concrete Institute (ACI) publishes ACI 318 which provides the minimum requirements for the design and construction of structural concrete buildings and structures. This standard covers topics like materials, analysis, design, detailing, construction, inspection, testing, and evaluation. The ACI updates its 318 standard periodically, taking into account emerging trends and practices in the industry. It also reflects the latest developments in concrete technology, structural systems, seismic design, and sustainability. In this blog, let’s explore the most recent version of ACI 318, ACI 318-19, published in 2019 and adopted by the International Building Code (IBC) in 2021.

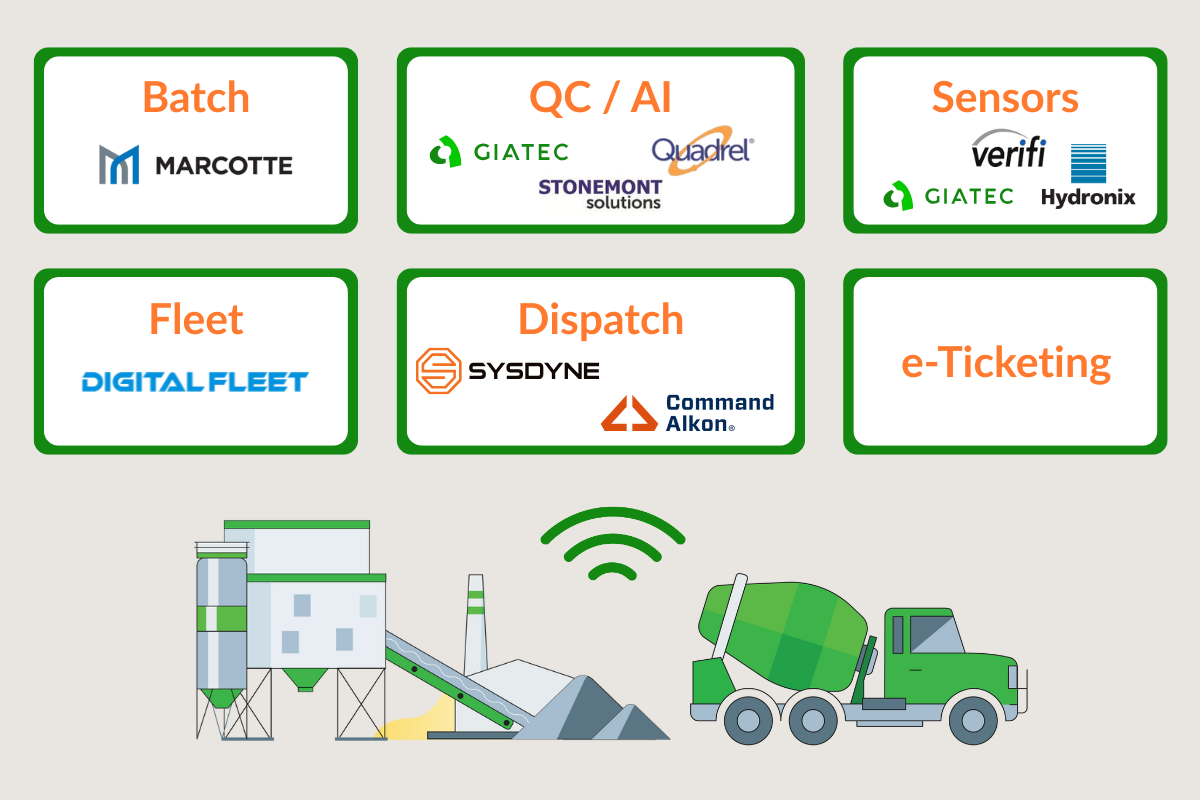

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Despite its main focus on concrete structures, this standard also spotlights non-building structures where applicable. Additionally, it includes commentary that explains the rationale and background of the code provisions. ACI 318 is widely used by engineers, architects, contractors, and building officials to ensure public safety and quality of concrete construction. Interestingly, ACI 318-19, which was published in June 2019 supersedes ACI 318-14.

What Are the Updates in ACI 318?

A new chapter on:

- Structural integrity consolidates provisions related to robustness and redundancy.

- Diaphragms that provide design requirements for floor and roof systems.

A new appendix on:

- Strut-and-tie models that expand the application of this method to deep beams, corbels, brackets, and dapped ends.

- Alternative provisions for reinforced concrete frames for seismic applications that allow the use of higher-strength materials and larger reinforcement ratios.

- Performance-based seismic design that provides an alternative approach to achieve a desired level of seismic performance.

- Precast concrete structures that provide design requirements for connections, joints, and anchorage.

- Post-tensioned concrete structures that provide design requirements for unbonded tendons and external tendons.

- Serviceability requirements that guide deflection, crack control, and vibration criteria.

- Durability requirements that guide exposure categories, concrete quality, and protection systems.

- Construction documents and inspection guide information to include in drawings and specifications and inspection and testing requirements.

The Importance of ACI

Before delving deeper into ACI 318, we must first understand the importance of ACI itself. ACI plays a vital role in the construction industry for several reasons:

Safety

ACI prescribes minimum design and construction requirements to prevent failures and accidents, which is critical in infrastructure and building projects.

Quality Assurance

It defines testing procedures and material specifications to ensure concrete mixtures’ consistency and performance, ideally achieving final products of established standards.

Design Consistency and Structural Integrity

As ACI specializes in providing guidelines for the design of concrete structures, this results in consistency that helps engineers create designs that are not only safe but also conform to industry-accepted practices.

Innovation and Research

ACI standards evolve to incorporate new research findings, materials, and construction techniques. The performance and sustainability of concrete structures can be improved on a large scale as ACI allows for the adoption of advanced technologies and encourages innovation in the construction industry.

Industry Best Practices

The standards devised by the American Concrete Institute involve a rigorous consensus-based process by a group of experts (committees) in the civil engineering field hence becoming industry best practice and serving as a representation of the collective knowledge of concrete professionals.

Durability

One of the most important key elements in any construction project is to achieve durability, that is the ability of the concrete structure to resist any adverse effects such as weathering action, abrasion, or chemical attack while maintaining its desired engineering properties. Different concrete require different degrees of durability depending on the exposure environment.

ACI standards address the durability phenomenon by specifying requirements for concrete mix designs, cover thickness, and protection against environmental factors such as corrosion freeze-thaw cycles and chemical exposure. This helps in extending the service life of concrete structures.

Some of the other notable characteristics of ACI standards include the following but are not limited to:

- International Acceptance

- Legal and Regulatory Compliance

- Environmental Considerations

- Risk Reduction

- Education and Training, etc.

ACI acts as an essential tool in ensuring the safety, quality, and performance of concrete structures. It serves as a foundation in the construction industry to create robust and long-lasting buildings while promoting innovation and sustainability.

Maturity Acceptance by ACI 318

According to ACI 318, maturity acceptance can be used as an alternative to field-cured cylinders for determining when a structure or structural element can be put into service. However, it cannot be used as a substitute for standard-cured cylinders for acceptance of concrete.

To use maturity acceptance, the following steps are required:

- Establish a maturity-strength curve for the concrete mixture by testing standard-cured cylinders and measuring the temperature history of companion cylinders or specimens.

- Install temperature sensors in the concrete structure or element at representative locations and depths.

- Record the temperature history of the concrete and calculate the maturity index using a maturity function or meter.

- Estimate the in-place strength of the concrete by using the maturity index and the maturity-strength curve.

- Compare the estimated strength with the specified strength or the strength required for a certain operation.

ACI – Reference for on-site Practices

In the concrete industry, the ACI is considered a very important document for structural engineers, architects, contractors, inspectors and everyone working with concrete structures.

Among the many topics highlighted in the ACI 318 standard, one of the key aspects is the specification of minimum and maximum reinforcement ratios for different reinforced concrete members, such as beams, slabs, columns, and walls. The reinforcement ratios are based on the material properties of concrete and steel, such as compressive strength, yield stress, modulus of elasticity, and strain limits, these ratios control the cracking, ductility, strength, and failure modes of the members under various loading conditions. As an add-on benefit, ACI 318 provides formulas and tables to calculate the minimum and maximum reinforcement ratios for distinct types of concrete members (beams, slabs, etc.,) and loading scenarios, thus satisfying the goal of providing minimum requirements for the materials, design, and detailing of structural concrete buildings.

ACI 318 Is a Must Have!

To summarize, ACI 318 is a must-have for all professionals engaged in concrete design, construction, and inspection. It helps to ensure that concrete structures are safe, reliable, and economical. Consequently, it promotes consistency and quality in the concrete industry. You can learn more about ACI 318 by visiting the American Concrete Institute website or studying the ACI 318-19 document.

Download our free quality control checklist to never miss a step in your pours!