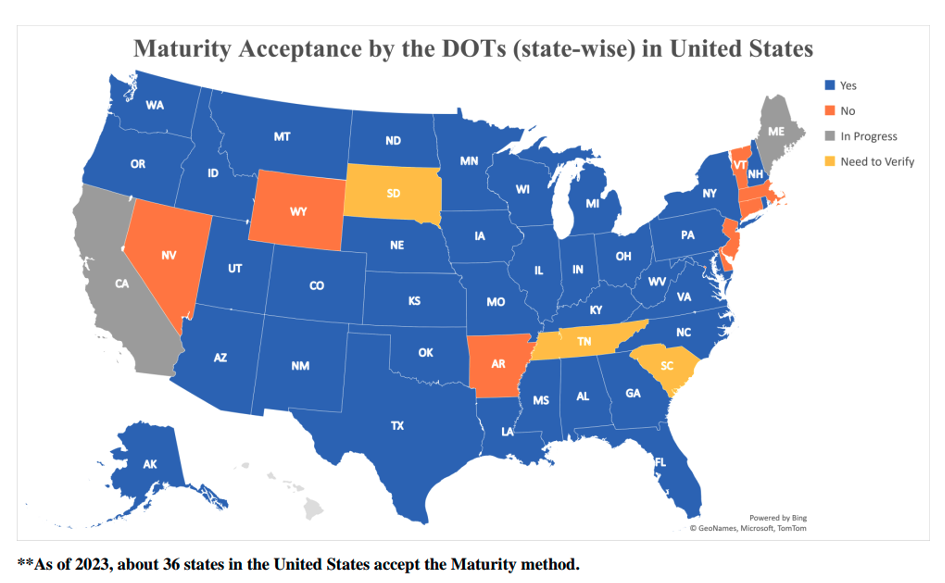

Today, many states’ Departments of Transportation (DOT) accept the maturity method as an essential tool to understand the strength development of in-place concrete for their infrastructure projects. More specifically, 36 states recognize the method as a reliable and accurate estimation method of concrete strength. This tool facilitates the decision-making process for project managers in terms of their concrete without compromising quality, time, or cost. In this blog, let’s explore how the maturity method works in DOT concrete and construction projects. We will learn how these departments optimize their resources while combatting the pressure of deadline constraints.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

How does concrete maturity fit into your project?

How Is the Maturity Method Used in DOT Concrete and Construction?

Let’s understand how the maturity method works. The maturity method is a non-destructive method to estimate the real-time strength development of in-place concrete. Specifically, it works at an early age of less than 14 days. In the 1950s, Nurse, McIntosh and Saul developed a relationship between temperature and time to determine concrete maturity. They called their method the Temperature-Time Factor (TTF). In the 1970s, Freiesleben-Hasen and Pedersen developed a different Maturity Method. This method is based on the Arrhenius equation and is commonly used in Europe. The Equivalent Age method as well as the TTF method are both standardized methods in several codes including ASTM C1074. In North America, most engineering professionals opt for the TTF method due to its simplistic approach to concrete maturity determination.

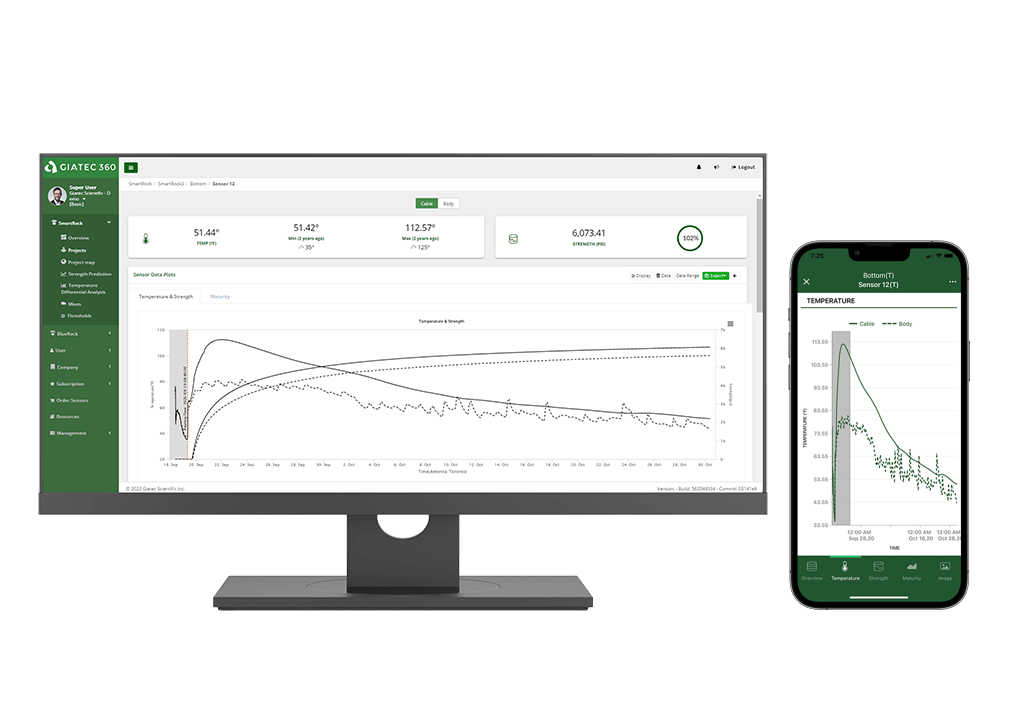

With the maturity method, one can determine an empirical relationship between concrete strength and the maturity index. Perform a calibration process specific to a mix design to achieve this. From there, one can use that technique in software technology to assess the maturity and strength gain of concrete structures. With that information, construction professionals working in maturity-accepting states can leverage data to improve project planning and risk assessment. Additionally, it helps the overall quality assurance in the monitoring, development, and maintenance of DOT concrete and construction projects.

Improving Project Planning

The maturity method aids project managers in planning certain construction operations in a timely matter. If the estimated concrete strength attained its critical operation strength in its early stages, the project manager can decide to strip the formwork of the in-place concrete element on time, or even earlier. That way, it minimizes prolonging formwork on the concrete element. This can delay later crucial operations, and milestones and incur unexpected costs. Alternatively, contractors can apply the same concept of stripping forms earlier to post-tensioning, saw cutting, opening lanes to traffic, etc.

Facilitating Risk Assessment

Within construction projects, risks are inherent. Thankfully, the maturity method assists in developing robust risk management strategies. This enables project managers to anticipate, assess, and mitigate risks effectively. For instance, if the field engineer notices that the temperature of the concrete approaches its datum temperature (typically 32o F according to ASTM C1074[1]), they would be aware earlier on that the concrete’s strength gain ceased or slowed down during that time. From there, they will be able to assess the situation early on, list possible risks that it can bring to their structure, and make calculated decisions accordingly.

Monitoring Infrastructure Development and Maintenance for DOT Concrete Projects

As mentioned, software and AI technology use this method. Use it to assess the maturity and strength gain of concrete structures. With that, project managers can monitor the maturity and strength of the concrete element throughout its curing and hardening phases. Additionally, project managers can continuously generate reports summarizing the results of the maturity measurements to deliver them to their respective DOTs. This constant documentation flow between the general contractor and the DOT will ensure the achievement of project quality goals and needs.

Recent advancements in wireless sensor technology, such as Giatec’s SmartRock® sensors, are now enabling DOT teams to implement predictive analytics in concrete testing. These predictive tools not only monitor real-time data but can also forecast concrete strength development under varying environmental conditions, allowing for proactive adjustments during critical stages of curing. This capability is especially valuable for complex, high-stakes projects like bridges and highways, where early intervention can prevent costly delays. As DOTs increasingly emphasize sustainability and resilience, the integration of AI with the maturity method is set to become a standard for optimizing concrete quality control in public infrastructure.

Conclusion

Ultimately, applying the maturity method for state DOT concrete and construction projects can lead to more efficient project management and reduced costs. This improves project delivery timelines and assists in the overall quality of construction projects.

This blog has been updated for clarity on October 30, 2024.

[1] According to ASTM C1074 Appendix X2, item X2.2 “For Type I cement without admixtures and a curing temperature range from 0 to 40 °C, the recommended datum temperature is 0 °C”