As we head over the 21st century, concrete professionals are facing the well-known issue of corrosion in concrete structures. On a regular basis, corrosion causes the gradual deterioration or degradation of affected concrete elements. The corrosion process initiates way before signs of degradation have shown on the outside of the concrete element. Thus, it is important to be aware of this issue to assure the long-term quality of your project. In this blog, learn more about the relationship between chloride diffusion and concrete corrosion. Also explore testing methods such as ASTM C1202, AASHTO T277, and RCPT.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Chloride Diffusion

One of the main causes of corrosion in concrete is chloride diffusion. Chloride can penetrate concrete and reach reinforcement externally from exposure to de-icing salts or seawater. It can also be present inside concrete ingredients. A passivating layer with a pH level of 13 to 13.8 provides natural protection to steel reinforcement. Once a certain amount of chloride reaches the reinforcement, the de-passivation of the reinforcement initiates. This process occurs in the presence of moisture and CO2 from the air. This brings down the PH level of reinforcement to lower than 9 at which point corrosion initiates.

Simply put, to a certain extent, chloride diffusion will cause reinforcement corrosion with the presence of CO2 and moisture. Corrosion causes the cracking of concrete, which allows for more moisture, CO2, and Chloride to penetrate more areas of concrete. It is a self-spinning cycle with a problem that grows larger with time if not dealt with appropriately.

The Importance of Permeability

Concrete’s mix design and internal properties such as the pore structure and its connectivity (i.e., Permeability), affect the amount and speed of chloride transport through concrete. The higher the permeability of concrete, the more chloride can ingress and transport through concrete.

Builders now construct concrete structures with specifications for low permeability. However, engineers need to evaluate the permeability of old concrete structures to avoid catastrophic events. Overall, it is important to measure concrete’s chloride permeability when evaluating and comparing concrete mix designs for new construction projects, as well as for the susceptibility to chloride diffusion in existing concrete structures. In other words, it is a way to measure concrete’s resistance to chloride diffusion.

ASTM C1202, AASHTO T277, and RCPT

Since chloride migration in concrete is a slow process, researchers have investigated testing methods that accelerate and measure chloride migration in concrete. As a result, we know now that applying an electrical current to a concrete specimen accelerates the process of chloride migration in concrete.

Thus, ASTM C1202 “Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration”, and AASHTO T277 “Standard Method of Test for Rapid Determination of the Chloride Permeability of Concrete” were developed, resulting in the Rapid Chloride Permeability Test (RCPT).

This testing method involves measuring the electrical current that passes through a 50 mm thick by 100 inches diameter sample. The sample is obtained from a concrete core or a cylinder sample, depending on the application, in six hours. Place the sample in the testing device cells and maintain a 60 Voltage DC across the ends of the sample for the duration of the test. Take readings every 30 minutes, then remove the sample from the cell at the end of six hours. Calculate the number of coulombs passed through the specimen.

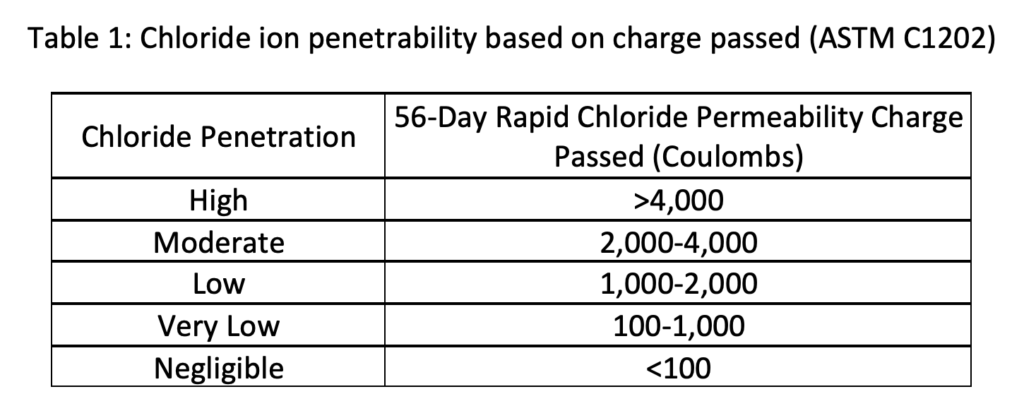

The correlations between the results of this test (charges passed) and the long-term chloride permeability of concrete established by ASTM C1202 are presented in Table 1.

The ASTM C1760 is another testing method for a rapid indication (i.e., in one minute) of the concrete’s resistance to the penetration of chloride by diffusion. The results of this test method can also be related to the apparent chloride diffusion coefficient that is determined using the ASTM C1556 test method.

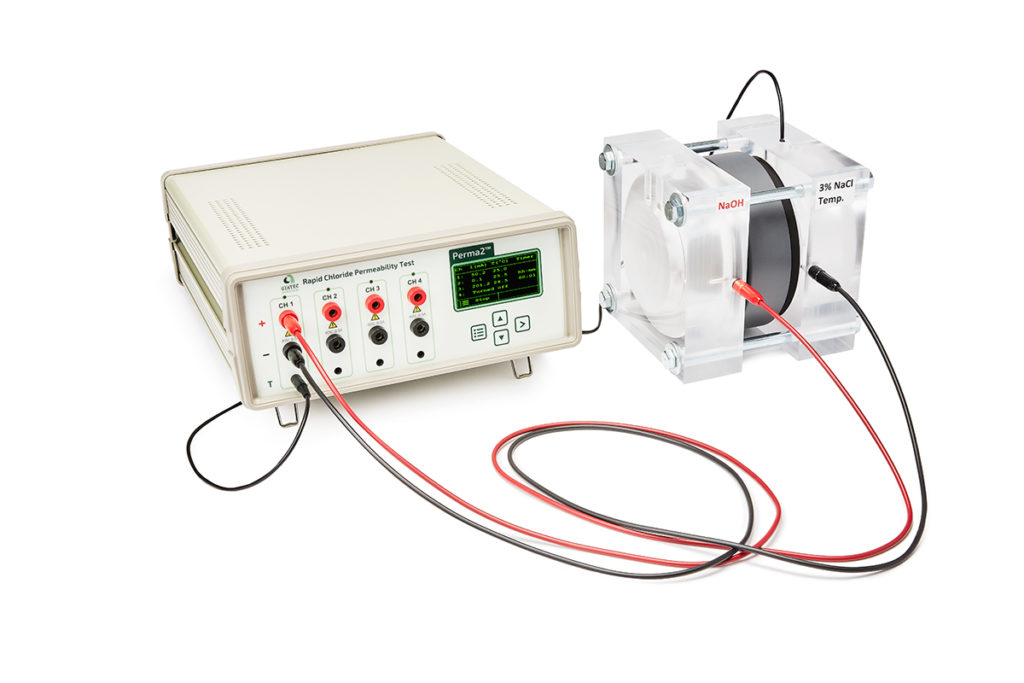

Giatec’s Perma2™ is a laboratory test device for the measurement of the resistance of concrete against the penetration of chloride (RCPT) according to ASTM C1202, AASHTO T277 and ASTM C1760 standards. Use the measurement data to estimate the chloride diffusion coefficient of concrete for predicting service life, designing durable concrete structures, and ensuring durability-based quality control.

Application:

Use the Perma2™ device to test the durability of concrete exposed to chloride-contaminated environments, including

- Concrete’s ability to resist chloride ion penetration (ASTM C1202, AASHTO T277), bulk electrical conductivity of concrete (ASTM C1760), and performance-based quality control of concrete

- Estimation of the chloride diffusion and chloride migration coefficient of concrete

- Service life design and estimation of the remaining life of concrete structures

Features:

The followings are unique features of this device

- Stand-alone operation, easy-to-assemble, auto-sealable cells with rubber gasket and spacer (i.e., does not require caulking), accurate (±0.1 mA), verification kit, flexible logging interval time (1 to 10 min)

- Automatic temperature control system, four measurement channels, user-friendly PC software, customizable setup, and a USB connection to the computer

Learn more about Perma2™ and the rapid chloride permeability of concrete here