Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

What Is a Concrete Thermocouple?

In layman’s terms, a thermocouple is an electric device that measures temperature, essentially making it a type of thermometer. That being said, it is not the kind of thermometer you would use to measure your body temperature when running a fever, or to deduce what the atmospheric weather is today, or as an in-built mechanism within your refrigerators and heaters. So, what exactly sets a concrete thermometer apart?

It takes two metals to form a thermocouple, both of which are wires that are welded, crimped, or twisted together, and the voltage is interpreted to determine the temperature. Heating metal wires causes the electrons within them to move, and once their potential for movement is sensed by a multimeter, this measurement can help us calculate the temperature. To quote Enercorp, “a thermocouple translates temperature energy into an electrical signal”.

Concrete thermocouples are used in the construction industry because of the several functions and benefits they provide, namely their accuracy in providing temperature data within two or three degrees of the actual temperature (which is acceptable due to the broadness of measurement ranges) and their cost-effectiveness. While they can sense a wide range of temperatures, they ultimately become susceptible to degradation, resulting in less accurate readings over time and wear. However, a short-term benefit is that thermocouples are resistant to breaking or other damages because they do not consist of fragile components or moving parts.

Click here to read more about why concrete temperature testing is important!

Different Types of Concrete Thermocouples

Before choosing a concrete thermometer for a project, it is essential to know and understand the types of concrete thermometers that exist in the market.

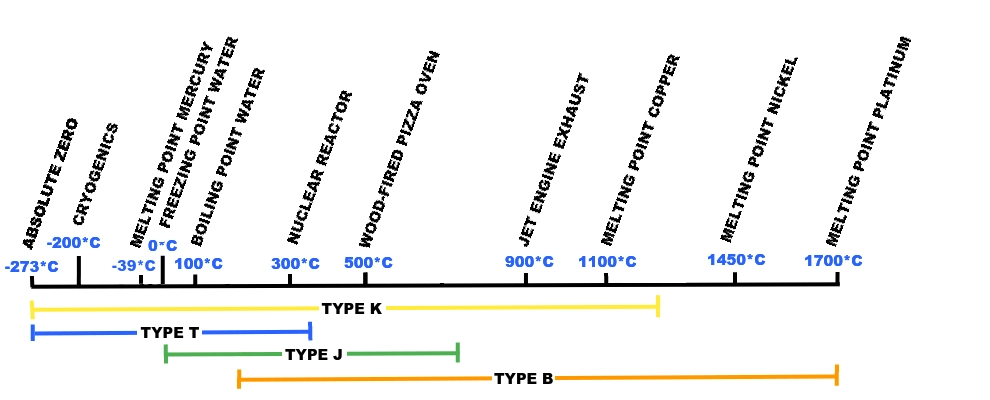

Type J

- This thermocouple type is made of iron and constantan (Fe-Con).

- This option is usually less expensive than others, yet it is the most accurate in the mid-to-low ranges.

- In higher temperature ranges, iron usually takes to rapid oxidization, potentially causing the standard voltage readings to be altered.

Type K

- Like Type J, this is also relatively less expensive than most of the other thermocouple types.

- It is manufactured with the combination of nickel-alumel and nickel-chromium alloys, is quite easy to use, and often produces accurate results even within a wide temperature range.

- This thermocouple can be used above the 1112oF (600oC) temperature mark.

- However, instead of the temperature reading, the data that this type produces is the voltage drop across the two wires.

- Knowing the voltage and matching it with a calibration chart can help you get an estimate of the temperature, but the process of obtaining such data for merely a single concrete slab would be highly time-consuming and repetitive.

- This is why many opt for more technologically-advanced devices like wireless concrete sensors, such as Giatec’s SmartRock®, which is fully embedded on the rebar with no wires and allows for quick decision-making onsite.

Click here to read more about monitoring concrete temperature with wireless sensors!

Type T

- This concrete thermocouple is applicable to colder temperatures.

- This type is made with the combination of copper and constantan (Cu-Con).

- Below –328oF (–200oC), it may gradually become inaccurate.

Type B

- Unlike Type T, Type B can be used for very high temperatures that range from anywhere between 392oF (200oC) to 3092oF (1700oC).

- However, this thermocouple type can also be significantly more expensive because it also incorporates two rare elements––rhodium (Rh) and Platinum (Pt)––in its application.

- This means that the Type B thermocouple is used under unique circumstances and very rarely found in the market for wide use.

Commercial Examples of Concrete Thermocouples

NEX®

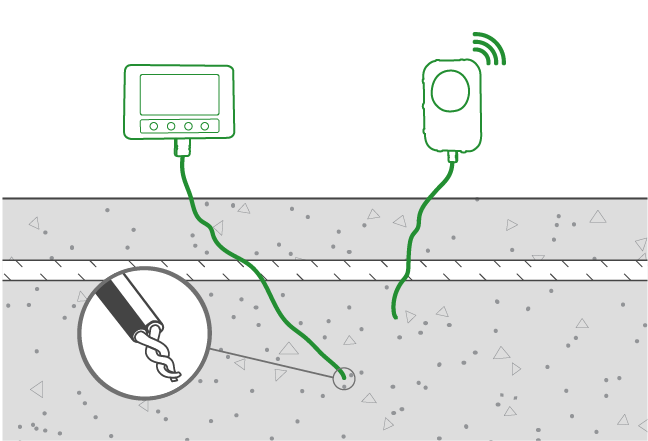

Con-Cure’s NEX provides wired temperature loggers are embedded in the concrete and the data obtained can be saved on an SD card. The wire lead that comes out of the concrete can be connected to a hand-held device so that the temperature data can be downloaded and recorded on Con-Cure’s maturity sensors or to a wireless node that transmits the data to the cloud through cell network.

ONSET’s HOBO provides multiple thermocouple wires that can be connected to a HOBO box which is installed outside the concrete, a regular logger which records the data that can be processed on a computer later, and a wireless logger that records and sends the temperature data via Bluetooth to a mobile device. This device has compact, weatherproof housing with built-in mounting, making it compatible with harsher climates. Their free HOBOconnect app lets users observe data in real time.

Sensohive’s Maturix uses thermocouple sensors for monitoring concrete temperature. One end of the thermocouple wires is embedded in the concrete, the other end needs to be connected to a node, and each wire needs to have a separate node. The nodes record the concrete temperature data and send it wirelessly to the cloud.

Choosing the Right Concrete Thermocouple for Your Project

There are quite a few concrete thermocouples to select from, but the one you ultimately choose will depend on your project specifications. However, you may prefer opting for methods that can help you collect concrete temperature logs offsite instead of onsite, or switch to more technologically-advanced wireless alternatives and web concrete monitoring devices instead. If that is the case for you, then we have got you covered!

Giatec’s wireless SmartRock® sensors are approved by the ASTM C1074 and ACI. They are fully embedded on the rebar with no wires or testing field-cured cylinders required, are easy-to-use, and allow for quick decision-making onsite. With this device, you can closely monitor temperature differentials between the core and edge of your mass pours with its dual temperature capability, i.e., two points of measurement in each sensor. The SmartRock app helps you tag sensors quickly via a QR code, receive proactive custom alerts and smart notifications, and provide multiple-company access to project data. The data is uploaded wirelessly to the cloud and you can also get alerts with Giatec 360TM, allowing you to easily follow your thermal control and curing plan. Giatec 360 is an advanced web-based dashboard for managing concrete pours, predicting concrete temperature, analyzing temperature differentials, and setting up thresholds for your pours. Choosing SmartRock means selecting an option that is easy-to-use, hassle-free, and allows for quick decision-making onsite!

Note: All company, product/service names, and brands used in this article are the property of their respective owners. This article is intended to be used for informational purposes only.

Sources

Enercorp: What is a Thermocouple?