Innovation in the construction industry has taken a whole new turn with the latest advances in 3D-printing technology. If you’re not already familiar with this technology, 3D printing involves a machine that uses concrete as its “ink” to construct buildings from the base up.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Layer by layer, the machine extrudes filament (in this case, concrete) and prints a structure based on the design file that was previously sent to the printer. So how does this apply to construction?

3D Printing in Construction

A number of companies including Contour Crafting Corporation, CyBe Construction, and Apis Cor have already created, tested, and used 3D printers for construction purposes.

Contour Crafting has created a variety of 3D printers, with their latest development being a lightweight machine capable of printing one concrete structure in one day. Due to its light weight, the 3D printer can be transported with a standard-sized truck and is easy to deploy anywhere that housing is needed. The method is extremely useful in regions that have been affected by natural disasters or in charity housing projects. The 3D printers also eliminate the need for construction workers, which in turn cuts project time and costs.

CyBe Construction uses a similar concrete 3D-printing method but on a larger scale. The company completed the construction of an 1,800 square foot research laboratory with their technology in just three weeks.

Last but not least, a video by Apis Cor demonstrates the process of 3D printing a house, all in a mere 24 hours. Although the initial build of the structure is fast, in pre-construction the concrete (or the “ink”) must be tested.

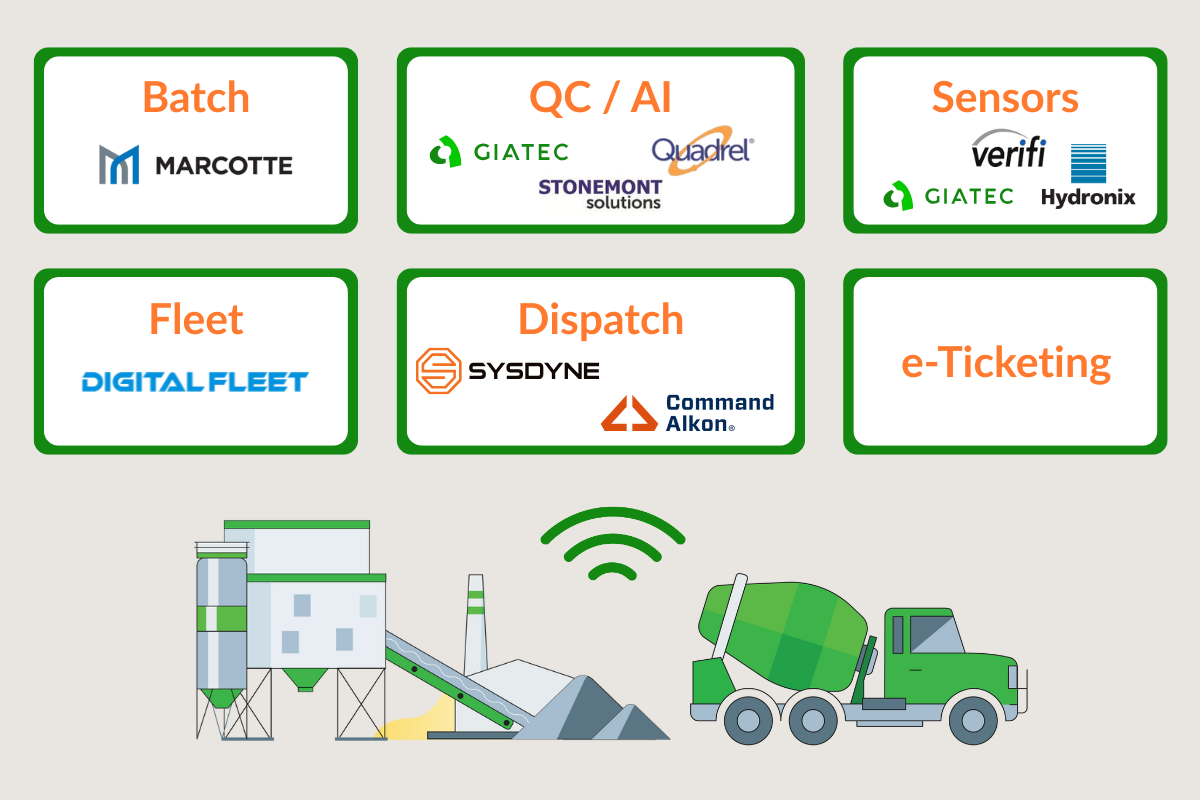

When it comes to quality control, the concrete can be tested using wireless smart concrete sensors to monitor the strength and curing of the 3D-printed concrete. This will ultimately save even more project time and costs, as resorting to traditional concrete testing methods like break tests can take days or even weeks.

Rapid, Low-Cost Housing Construction

In many places around the world, the cost of housing has increased due to high demand. And as the world’s population grows, rapid production of housing at a low cost will become essential. With the world’s population expected to reach 11 billion by 2100, the time and cost savings associated with 3D printing will establish the technology as an excellent alternative to traditional construction methods.

Furthermore, concrete structures are alrady known for their durability and longevity, and resistance to mold, fire, pests, and other external conditions. These are just some of advantages we are looking forward to seeing with the use of 3D-printing technologies in concrete construction.

Sources:

Contour Crafting begins series production of deployable construction 3D printers

3 Responses

Dear Sir,

Can you provide a quotation of robotic arm-based 3D printer on my given email, please?

Hi there, thank you for your comment. Unfortunately we do not sell this product.

Eventually the 3DCP industry will realize that the top down nozzle extrusion system with all of its limitations is simply antiquated and that the next generation of practically implementable 3DCP technology is already patented but not widely spoken about just yet.