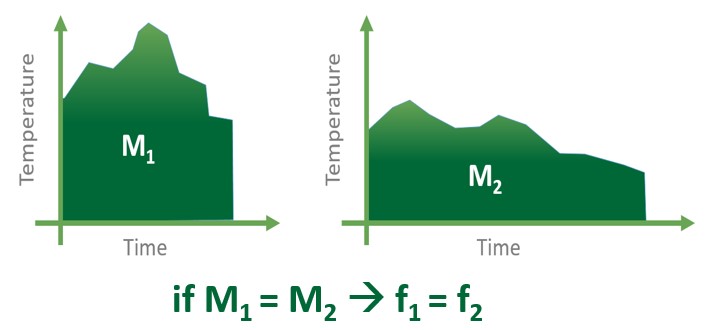

The concrete maturity method ASTM C1074 is a non-destructive approach that allows the estimation of the strength of in-place concrete. The method uses the temperature history of the concrete during the curing phases to estimate strength development.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

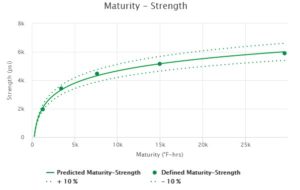

Relationship between the strength and the temperature history of a given concrete mix design.

This approach requires calibration to create a unique relationship between the Maturity Index (obtained using the temperature profile) and concrete strength. For example, this means that a given concrete mix can reach the same strength after 7 days curing at 50°F (10°C) as when it is cured at 68°F (20°C) for 3.5 days

Maturity Calibration and ASTM C1074

There are different methods to develop the maturity calibration. However, all of them are dependent on the temperature history of the mix-design. The most commonly used in North America is the Temperature Time Factor (TTF), as it is simpler to implement. TTF is also known as the Nurse-Saul maturity function. For more information about other methods, refer to the maturity ebook.

- Prepare a minimum of 17 cylinders (2 for temperature and 15 for breaks)

- Provide same curing condition for all the cylinders (ASTM C1074 states that, if not specified specimens must be moist cured)

- Break 2 cylinders for each day of the calibration and use the average strength result. Note that using a third cylinder is only necessary if the difference in strength exceeds 10% of the average.

Calculate maturity for each day of the calibration and use the average maturity result.

- Develop the curve plotting the maturity index x strength results.

*Further steps will be required if the datum temperature needs to be calculated instead of approximated. The datum temperature explanation is covered below.

What Is the Datum Temperature?

The datum temperature is defined as the temperature at which the hydration of the cement stops. In other words, the temperature at which concrete stops developing strength. It is essential to a maturity calibration, as it is the baseline in which the maturity index can be calculated.

According to ASTM C1074, the recommended datum temperature is usually taken as 32°F (0°C) for Type I cement without admixtures and a curing temperature range from 32°F (0°C) to 104°F (40°C). This parameter can also be calculated experimentally using Appendix X.1 of the ASTM C1074 standard. One can also refer to section 4.1.1 in the maturity ebook.

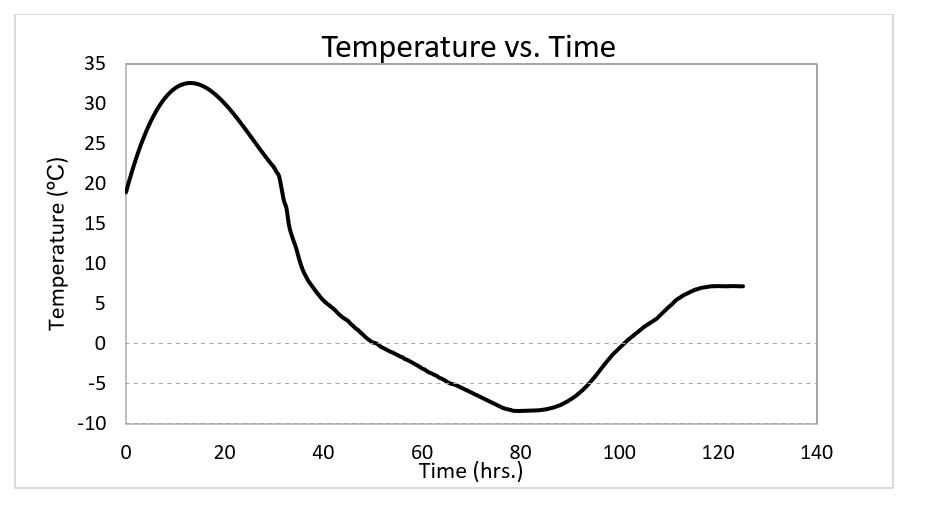

In simpler terms, every time the temperature drops below the established datum value, there will be no strength gain until the moment the concrete goes back above this reference. Taking the graph below as an example, if the reference is a datum temperature of 32°F (0°C). In the period between hour 50 to hour 100, the concrete did not develop any strength. However, if the datum temperature calculates to be 14°F (-10°C), the concrete stood gaining strength throughout the entire period. With this in mind, the datum temperature is one key factor for all maturity calibrations. Using a value that does not represent the mix used can lead to inaccurate results.

What Can Affect the Maturity Calibration?

The maturity calibration associates with a specific mixture design. This takes into consideration its properties. As a rule of thumb, any changes in the mix design will have a direct impact on the calibration. However, it is unrealistic to assume that all concrete batches will be equal to the one used for the calibration. Therefore, it is commonly accepted that any changes in the concrete chemistry will have a direct impact on the maturity calibration (i.e. accelerators, retarders, change in the type of cement, SCM’ – Supplementary Cementing Materials, etc).

Nevertheless, assuming that any changes in the mix affect the calibration, it is important to take into consideration the type of application and the correlation of impacting factors to the maturity curve. In the case of accessing the early age strength results with maturity, any component that affects the rate of strength gain at an early age level will have an even higher influence on maturity. For instance, if the strength target is 3000psi (20 MPa) at 24 hours, the addition of retarders or accelerators to the mix would greatly affect the maturity calibration.

To check and analyze if a factor will affect the maturity calibration, one can ask:

- Would this adjustment in my mix change the strength data at given ages?

- Recently my producer made a small revision to the mix, should I submit the mix for reapproval?

- Would this modification in my mix change the temperature of my concrete?

At any point where the temperature or the strength profile is affected, the mix should be recalibrated.

Should Mix Calibration Include Factors of Safety?

Maturity follows the procedure outlined by ASTM C1074, which does not recommend factors of safety in the current 2019 version. However, as a decision from the designer or the engineer in charge, one can build the calibration curve with a mixture that still meets the specifications but with a slightly higher water/cement ratio and air content (as expected in the field).

Furthermore, building the calibration with the concrete poured on-site help to set a baseline and correlation with the real concrete delivered. For instance, if additives/additions are added at the job site, it is fundamental that the calibration is done using the same concrete being poured. This action will ensure that the calibration takes into consideration all characteristics of the mix used in the concrete elements.

Furthermore, RILEM Committee TC’s ATC report (2005) proposes an equation to incorporate into the maturity calibration as a safety factor.

How Long Is the Calibration Valid For?

The calibration is valid as long as nothing in the mix changed. However, no changes in the mix throughout a long period is unrealistic. This is especially due to seasonal changes and the adjustments required from the producer side. As per section 9.5 in ASTM C1074, one can check the strength results from cylinders subjected to standard curing condition (ASTM C31/C31M) and strengths estimated from the established strength-maturity relationship. If the difference between the results consistently exceeds 10%, developing a new strength-maturity relationship is necessary.

When utilizing the maturity method for critical operations (i.e stressing cables on PT elements, formwork removal, etc), it is of great importance to check the mix regularly. This ensures that the results are constantly within the 10% tolerance, according to ASTM C1074.

Are There Any Tolerances With the Maturity Method?

There are two standpoints when referring to the tolerance of the maturity method. The first one addresses the calibration procedure. ASTM C1074 outlines that, when performing the calibration, the range of compressive strength of the two specimens (of each break date) cannot exceed 10% of their average. If any individual break result exceeds 10%, testing the third cylinder is imperative. One must then compute the average of the three tests.

The second standpoint relates to the use of a pre-established maturity in the field. As described in the previous topic, the differences cannot consistently exceed 10%.

What Are the Differences Between Results From Field-Cured Specimens and the In-Place Strength of Concrete?

One of the main advantages of the system relies on the opportunity to achieve the desired strength result earlier than expected. It can also measure the real strength in the concrete element. When using only concrete cylinders to check the strength results of the in-place concrete, one does not take into consideration the real behaviour of the concrete element. The volume in a concrete element is much greater than in concrete cylinder/cube, generating more heat and, therefore, strength gain. Furthermore, concrete samples have a bigger relative surface compared to its volume. This means that the capability of retaining heat is smaller than a concrete structure.

Also, maturity helps to identify and measure critical locations in the real concrete structure. For example, due to external factors, a slab can have different strength development in different locations. A higher incidence of the sun/shadows and wind on another location can cause this behavior. Additionally, the last-placed concrete is the last to start developing strength. Therefore, this location will generally have lower initial results if compared to the first concrete placed, where the hydration process is further ahead.

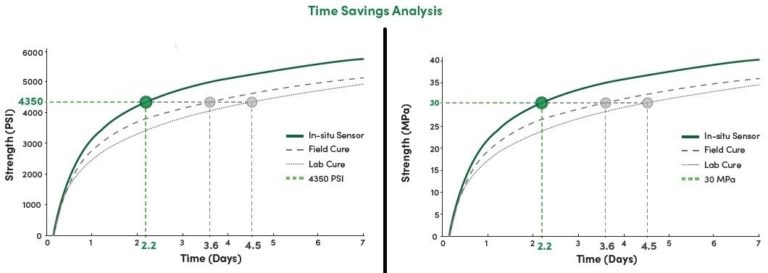

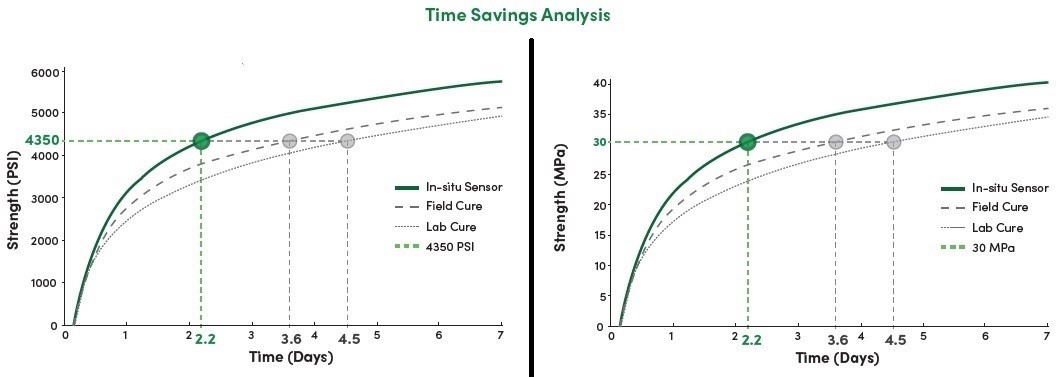

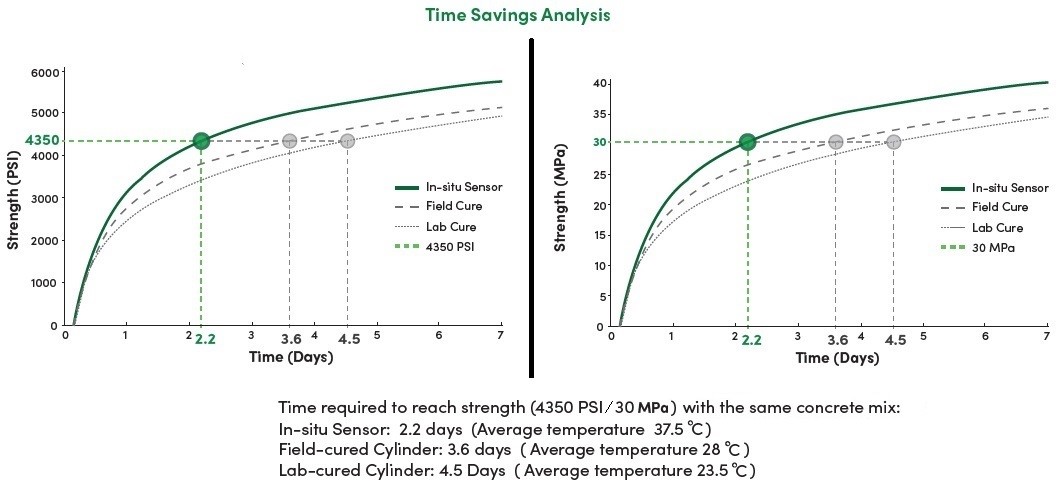

Below we Illustrate an example of time savings based on the strength obtained through various methods, with the same concrete subjected to different curing conditions.

As observed above, the in-situ concrete achieved the required strength roughly within half the time the lab-cured cylinder achieved the same strength. This time difference can be crucial to a job site schedule and the gains with the maturity are certainly noticeable. Furthermore, each project will have a different analysis, as weather and production conditions vary from location to location.

In cold weather conditions, the opposite might also be true where the structural element can be under colder temperature than the field cured and the lab condition.

What Are the Main Applications for the Maturity Method?

The maturity method covers a wide range of applications. This can include: helping earlier formwork removal, enabling the stressing of cables on PT slabs/beams, opening lanes to traffic as fast as possible, vertical work and tilt-up. Once a curve is established, one can track the real strength results on bridges, building & highrise projects, highways & roads, post-tensioning, mass pour and concrete testing.

Read more about our case studies here!

Where Is It Better to Cast Cylinders for Maturity? Lab or On-Site? What Are the Differences?

For calibration, ASTM C1074 outlines that the cylinders shall be similar to those of the concrete whose strength will be estimated using this practice. Therefore, concrete cylinders can be cast on-site, the lab or at the batch plant. There are three important measures. Firstly, all cylinders (the ones for temperature control and break results) must be kept in the same curing conditions (ASTM C1074 outlines that unless specified otherwise cylinders must be moist cured). Secondly, they should come from the same batch and mix-design. Third, the curing condition must be in accordance with standard practices. As such, one should decide on a case-by-case basis. ‘Are there any special additions to the mix on site?’ ‘Is my job site far from the batch plant?’. In most cases, the preferred approach would be the casting in the job site, directly from the poured concrete.

Can I Use Maturity for Flexural Strength?

Yes. Section 8.7 in ASTM C1074 permits a flexural strength x maturity relationship if specified. In this case, instead of 15 cylinders, one must prepare at least 15 beams specimens. This is in accordance with ASTM C192 – Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory.

When using SmartRock technology, if the application is for compressive and flexural strength, both maturity calibrations will be available when calculating the strength of the in-situ element. Following simple actions, one will be able to check these strengths within seconds. This solution is especially useful in cases such as highways & roads, bridges, tilt-up concrete, mass concrete and other applications where the flexural strength is a parameter in analysis.

I Have an Early Age MIX, How Should I Build My Maturity Calibration Curve?

A calibration is always specific to a mix design. Choosing the break schedule that best reflects the critical operations on-site is very important. ASTM C1074 requires compression tests at ages of 1, 3, 7, 14 and 28 days unless specified otherwise. However, maturity is most commonly used for early age strength prediction. Thus, having more breaks at the initial stages of the strength progression is fundamental. As a baseline to achieve good accuracy in the maturity curve, one can assume 2 break points before the critical operation and 2 break points after, being the critical operation the center data point.

For instance, if the critical operation for stressing cables in a post-tensioned slab is 4,000 psi (27.5 MPa) within 24 hours, it is important to develop the strength-maturity relationship in the first hours. In this example, one could correlate the maturity with the strength at 12h, 18h, 24h, 3 days and 7 days, as the objective is to accurately estimate the initial strength. ASTM C1074 asks for a minimum of 5 data points, but if desired more accuracy on later or earlier ages, one can add more points to the calibration.

Calculate maturity for each day of the calibration and use the average maturity result.

Calculate maturity for each day of the calibration and use the average maturity result.

2 Responses

Hello Mr. Mariani:

I am writing numerical example for young engineers. I downloaded your eBook on Maturity method but did not find examples.

My question is: Do you have some examples that show the application of the method in a step-by-step way to a young engineer? for example:

1. taking temperature reading. what interval?

2. taking and plotting data for temp-time curve.

3. calculation on maturity index (it is an easy step of integration) is regression method needed?

3. relate test data to strength prediction.

Thank you. 847-323-0800

Hello, thank you for your question and interest. Unfortunately, we do not have numerical examples ready. However, as the Maturity Method is standardized by the ASTM C1074, it is possible to create examples from the Standard and from the Calibration section of our maturity eBook (pg. 35).