Concrete is a key construction material known for its strength and adaptability. Its performance is also dependent on managing its setting times. This blog will explore the science behind the initial and final concrete setting times. Factors such as temperature, humidity, and mix composition influence these setting times. We will also discuss how modern technologies like SmartRock® sensors are enhancing concrete curing practices, leading to improved quality and durability of structures.

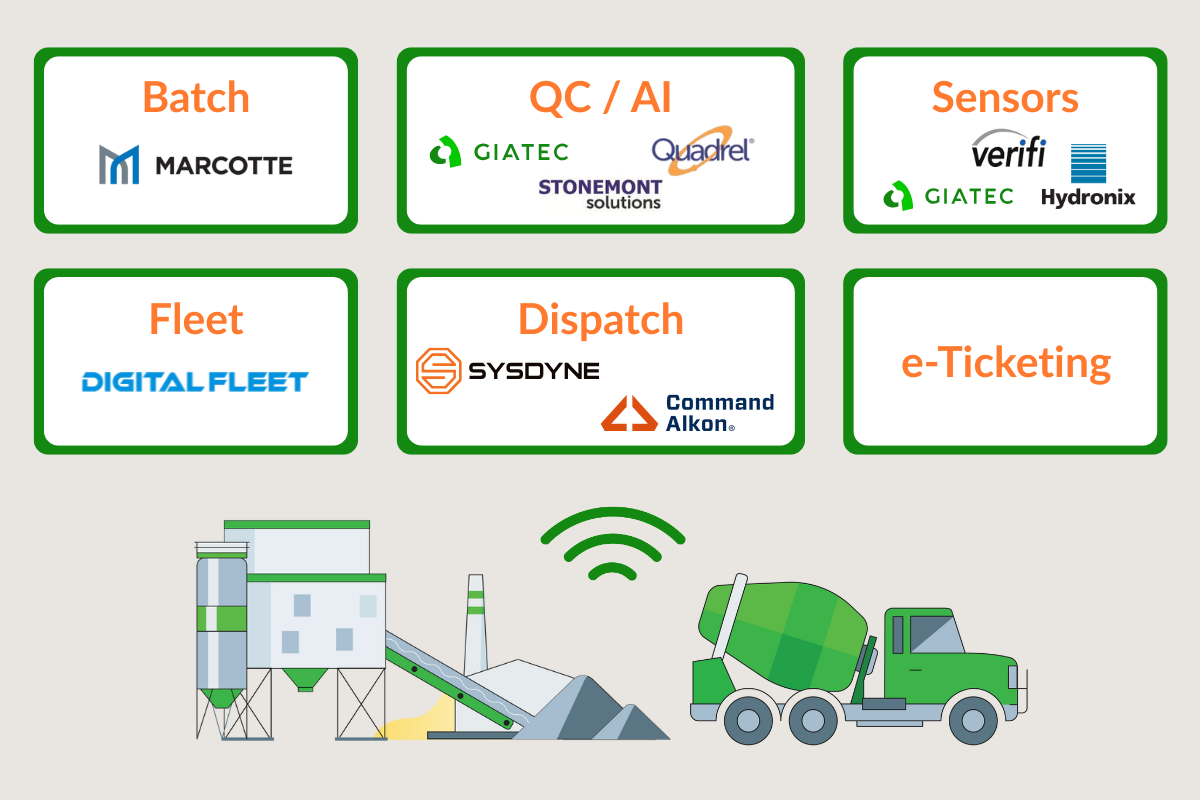

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

What Are the Initial and Final Concrete Setting Times?

- Initial Set Time: Refers to the point at which the concrete begins to harden to the extent that it can no longer be worked or molded. At this stage, the concrete’s consistency is changing from a fluid state to a more rigid one. Concrete starts losing its plasticity and starts becoming more solid, taking the shape of the mold its poured in.

- Final Set Time: This is when the concrete has hardened sufficiently so that it can no longer be deformed by pressure. At this point, the concrete has finished the setting time and has started its strength gain process.

The setting times are influenced by several factors including temperature, mix design, and the presence of chemical admixtures.

What Factors Affect the Setting Times of Concrete?

Temperature

Temperature plays a significant role in the setting times of concrete. Higher temperatures accelerate the hydration process, leading to shorter setting times, while lower temperatures slow it down. According to the American Concrete Institute (ACI), the rate of hydration increases significantly with temperature, which can affect both the initial and final set times (ACI 306R-16).

Mix Design

The proportions of cement, water, and aggregates, along with the type and amount of admixtures, influence setting times. For instance, using a high amount of cement or specific types of cementitious materials can alter the hydration kinetics. This affects setting times. Higher cement content increases the rate of hydration reactions due to the greater availability of reactive particles. In turn, this can lead to faster initial and final setting times. Additionally, the type of cementitious materials used, such as different types of Portland cement or supplementary cementitious materials (SCMs) like fly ash or slag, can impact the setting times. For example, SCMs often slow down the hydration process, leading to extended setting times compared to traditional Portland cement. This variability is due to differences in chemical composition and reaction rates of the various materials, which influence how quickly the cement paste transitions from a fluid to a hardened state.

Admixtures

To modify the setting times, it is useful to use chemical admixtures such as accelerators and retarders. Accelerators speed up the setting process, which is beneficial in cold weather, while retarders slow it down, which can be useful in hot weather or for long transportation times.

Water-to-Cement Ratio

The ratio of water to cement affects the hydration process and, consequently, the setting times. Higher water content can delay the setting time as more water slows down the rate of hydration.

How to Measure Concrete Setting Times?

Vicat Apparatus

The Vicat Apparatus method, described in ASTM C191, is another technique to measure setting times, though it’s more applicable to hydraulic cement rather than concrete. This method uses a needle to penetrate a cement paste, and the depth of penetration helps determine the setting times. The Vicat’s needle is lowered into the paste at regular intervals, and the time at which it penetrates to a predetermined depth signifies the initial and final setting times. While this method provides valuable information about the setting characteristics of cement, it is less common for concrete mixtures in comparison to other methods due to its focus on cement pastes. See Figure 1 for reference.

Field Methods

In practical field settings, construction professionals often rely on visual and tactile assessments to gauge concrete setting times. Skilled workers can observe changes in the concrete’s consistency and handling characteristics to estimate when it has reached its initial set stage. While these methods provide informal indicators and are not as precise as laboratory tests, they offer a quick and practical way to monitor setting progress during the construction process. Combining these field methods with more precise testing techniques can enhance the overall accuracy and reliability of setting time measurements.

How Does Concrete Setting Time Relate to SmartRock Sensor Data?

Modern technologies, such as Giatec’s SmartRock sensors, offer advanced methods to monitor concrete curing. The sensors use the maturity method to estimate the strength of concrete by measuring the temperature of the curing concrete over time. The maturity method, described in ASTM C1074, uses the temperature-time history of concrete to predict its strength development.

Pouring Time vs. Set Time

While SmartRock sensors can detect concrete pouring and monitor the curing process, they do not measure the exact setting times. Instead, they provide insights into how the concrete’s strength develops over time, which is crucial for determining when the concrete is ready for further construction activities.

Conclusion

Understanding the setting times of concrete is essential for successful construction projects. The initial and final set times are influenced by a variety of factors, including temperature, mix design, and admixtures. SmartRock sensors provide valuable data on concrete strength through the maturity method, they measure strength development rather than direct set times. By combining sensor data with traditional testing methods, construction professionals can achieve more accurate and reliable results, ensuring the durability and safety of their concrete structures.