You already know the importance of modern technology in your construction team’s daily operations. A recent AGC survey showed that most contracting firms agree that modern technology improves workforce skills and thus, the result of their operations. Ultimately, bringing innovations to the jobsite can have great benefits when it comes to cost and time reductions. In this blog, we will follow along with some of the most impressive innovations that Giatec has been working on when it comes to concrete technology. Then, we will read about the benefits for construction teams and their impact on the overall success of a project.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

3 Concrete Technology Innovations Breaking Into the Industry

Wireless Concrete Sensors

Giatec’s flagship product, the award-winning SmartRock® wireless concrete monitoring sensor, has garnered global trust among project leaders. These innovative sensors provide teams with 24/7 real-time access to crucial concrete data, regardless of location. With a wireless range of up to 40 feet (12 meters), SmartRock sensors enable faster, data-driven decision-making by offering instant insight into concrete performance.

The functionality of SmartRock is straightforward yet highly effective. Utilizing the ASTM and ACI-approved maturity method, this concrete technology delivers highly accurate and reliable on-site concrete strength assessments. This surpasses traditional field-cured cylinder tests, which are time-consuming and harder to control. Not only SmartRock is robust and easy to use, but it is also an easy-to-install concrete technology. Once it’s activated and embedded in the rebar, contractors can simply pour the concrete and begin monitoring temperature and strength gains immediately.

As an Internet of Things (IoT) solution, SmartRock seamlessly connects to mobile devices and web dashboards. This makes it very easy to obtain real-time reports and provide it to all stakeholders. As a result, this integrated approach helps teams streamline decision-making both on-site and remotely, ensuring efficient project management from start to finish.

Long-Range Technology

While wireless concrete sensors offer significant advantages by transmitting real-time data, some construction scenarios present unique challenges, particularly in remote locations. Projects such as highway construction or high-rise buildings may face connectivity issues. These can happen due to limited LTE signal or the number of floors involved. Additionally, a shortage of personnel in these remote areas can make timely data acquisition more difficult.

In such cases, long-range systems become essential technological innovations. Giatec’s SmartRock and SmartHub™ Long Range solutions bridge that gap, ensuring that critical concrete data is accessible even in hard-to-reach areas. On the one hand, SmartRock’s extended wireless range of up to 1,000 feet (300 meters) allows for optimal remote monitoring. On the other, SmartHub connects automatically to up to 100 sensors on-site, delivering unmatched remote performance. Together, these systems and concrete technologies empower teams to monitor concrete temperature and strength effectively, even when mobile phones alone cannot provide adequate access to data.

Get all the details of SmartRock Long Range and its applications!

AI-based Concrete Mix Optimization

The increasing adoption of Artificial Intelligence (AI) in the construction industry offers a transformative opportunity to tackle persistent industry challenges. These are labor shortages, fragmented concrete data, and inefficient concrete mix designs. Overdesigning concrete mixes, in particular, leads to excessive material use, inflating costs and contributing to environmental waste. Reducing this waste is crucial for contractors and ready-mix producers aiming to enhance competitiveness in the concrete industry.

Giatec is at the forefront of addressing this issue with SmartMix™, an AI-powered system that revolutionizes concrete mix management. By analyzing data from ongoing concrete operations, SmartMix provides immediate reports and actionable insights. Through concrete technology, this enables producers to optimize mixes and reduce waste. The software generates multiple mix scenarios in seconds, presenting the impacts of each option to help producers select the most efficient mix every time. Its predictive capabilities allow for rapid adjustments and large-scale optimizations, ensuring that decisions are made quickly and with confidence.

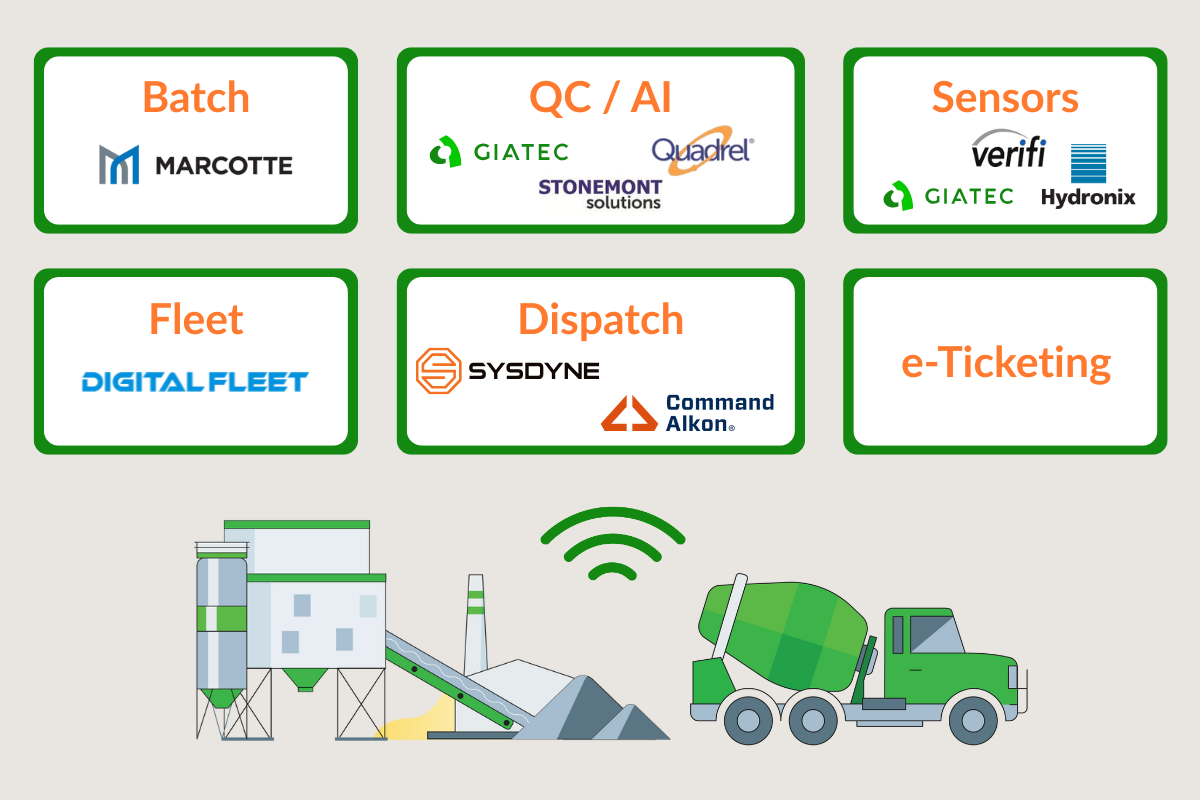

Interested in AI for concreting? Read all about interoperatiblity at the jobsite here!

Embracing Concrete Technologies to Improve the Industry’s Future

As the construction industry continues to evolve, the role of technology has never been more critical in driving efficiency, reducing costs, and ensuring sustainability. Giatec’s innovations—whether through wireless concrete sensors, long-range monitoring solutions, or AI-based concrete mix optimization—demonstrate how the most modern tools are reshaping how teams approach project management, data accuracy, and resource efficiency. These advancements not only streamline operations but also address common industry challenges. By embracing concrete technologies, contractors and managers can expect to improve productivity, make better data-driven decisions, and ultimately deliver more successful projects. The future of construction lies in leveraging the best innovations to stay ahead in an increasingly competitive landscape.

Read more on the top solutions for your construction challenges in 2025!