The concrete industry has long been known for its slow adoption of new technologies. While this caution may serve to maintain traditional methods, it leaves ready-mix operations vulnerable to a major digital-age challenge: cybersecurity. As the industry embraces digital tools and AI-driven solutions, many businesses find themselves unprepared to tackle the cybersecurity threats that follow.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Another factor contributing to this challenge is the lack of awareness about cybersecurity practices among employees. Without proper training and protocols, businesses risk falling victim to cyberattacks that can disrupt their operations and compromise sensitive data. People are often considered the weakest link in cybersecurity, especially employees who are less familiar with digital tools and practices. For instance, concrete truck drivers who may not engage with technology as frequently can become more vulnerable to cyber threats. This blog explores cybersecurity challenges for concrete producers and outlines strategies to improve security in today’s digital landscape.

The Security Gap in Technology Adoption

Ready-mix concrete companies face unique cybersecurity challenges as they integrate new technologies into their operations. Many businesses have outdated systems, which can be easy targets for cybercriminals. Additionally, the industry’s fragmented nature often leads to inconsistent security practices across different teams and locations.

Moreover, employees in the concrete sector may not fully understand their role in maintaining cybersecurity. This lack of awareness can result in poor password practices, insufficient email filtering, and inadequate training on recognizing phishing attempts. As a result, this can make it easier for hackers to gain access to sensitive data and disrupt operations.

Enhancing Cybersecurity Awareness and Practices

Getting started on a cyber safety plan can be overwhelming, but concrete producers can start with the following tactics to get moving:

- Implementing Multi-Factor Authentication (MFA): Enforcing MFA adds an additional layer of security, making it more difficult for unauthorized users to access sensitive information.

- Establishing Password Policies: Strong password enforcement policies can also help reduce the risk of unauthorized access. Hence, regularly changing passwords and using complex combinations is important.

- Conducting Regular Training Sessions: Ongoing education on cybersecurity best practices, including recognizing phishing attempts and safe browsing habits, is crucial for all employees.

- Designating a Security Officer: Appointing at least one dedicated individual responsible for cybersecurity ensures accountability and oversight of security measures within the organization.

- Choosing a Strong Cybersecurity Provider: Partnering with a trusted cybersecurity provider, such as KnowBe4, can help implement effective solutions to keep up with evolving threats.

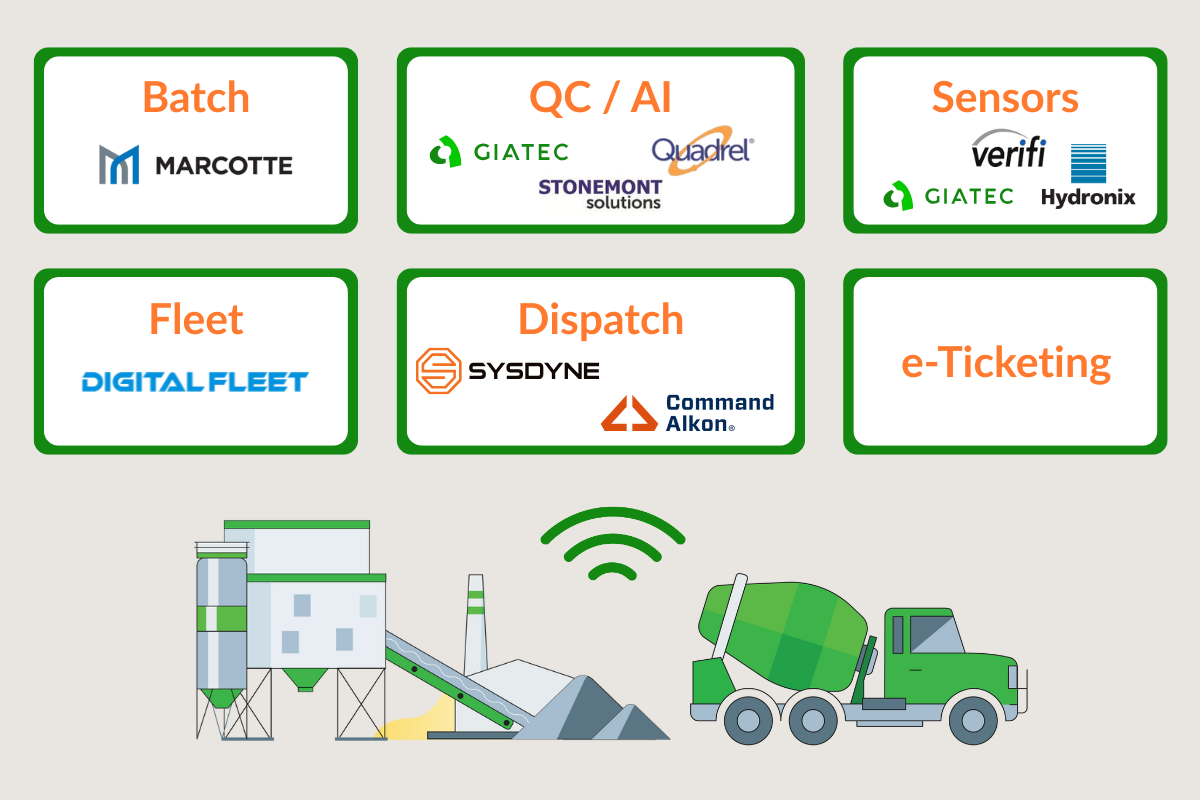

Embracing Artificial Intelligence and IoT Solutions

As the concrete industry embraces advanced technologies, the need for enhanced cybersecurity measures becomes increasingly important. While AI and IoT tools offer endless opportunities to optimize operations and improve efficiency, they rely heavily on data. This reliance makes them potential targets for cyber threats. To mitigate these risks, organizations must strengthen their cybersecurity frameworks alongside implementing these solutions. By doing so , they can confidently leverage innovative tools while maintaining both operational excellence and data security.

For instance, Giatec® SmartMix™, an AI-powered mix management system, optimizes concrete mix designs and enhances efficiency for ready-mix concrete producers. It offers remarkable benefits, including streamlined operations and better resource allocation. However, its implementation requires a thorough examination of existing security practices. Ready-mix concrete companies must integrate AI systems into a robust security environment, ensuring data encryption, conducting regular security audits, and continuously monitoring for suspicious activities.

Additionally, IoT technologies like SmartRock® Plus are enhancing security in the industry by providing producers with real-time visibility into the condition of their concrete. SmartRock Plus is a wireless sensor that remotely monitors temperature and strength, helping producers monitor their concrete as it cures. By gaining this level of visibility into the condition of their concrete, producers can make informed decisions that enhance both operational efficiency and data security.

Safeguarding Your Ready-Mix Operations

As the ready-mix concrete industry moves toward greater technology adoption, the importance of robust cybersecurity measures cannot be overstated. By prioritizing cybersecurity awareness and implementing strategic practices, companies can better protect their operations against evolving threats. Embracing AI and other advanced technologies should not come at the expense of security. Rather, it should be accompanied by a commitment to safeguarding sensitive information and ensuring operational integrity.

With proactive measures in place, our industry can confidently navigate the challenges and opportunities that come with technological advancement. As the migration to more sophisticated, cloud-based systems continues, businesses must be prepared for the challenges of this transition.

For further insights on navigating cybersecurity in the concrete industry, be sure to check out our podcast episode, “The Concrete Approach to Cybersecurity Challenges”. In this episode, Andy Barnes, Chief Information Officer at Blue Dot Readi-Mix, shares best practices for safeguarding your ready-mix operations. Don’t miss this opportunity to learn from an expert and strengthen your business’ cybersecurity stance!