The fast-paced environment of the construction industry results in a constant search for better and more efficient ways to evaluate the quality of concrete. Despite the increase in modern knowledge regarding concrete research, current industry practices still rely on compressive strength testing to measure concrete quality. However, the results of a compressive test alone do not represent the quality or durability of the concrete. In this blog, learn about how concrete resistivity tests can help the industry as well as the different ways we can evaluate concrete’s durability through electrical resistivity testing.

Detect the Rate of Rebar Corrosion in Seconds

The Problem With the RCP Method

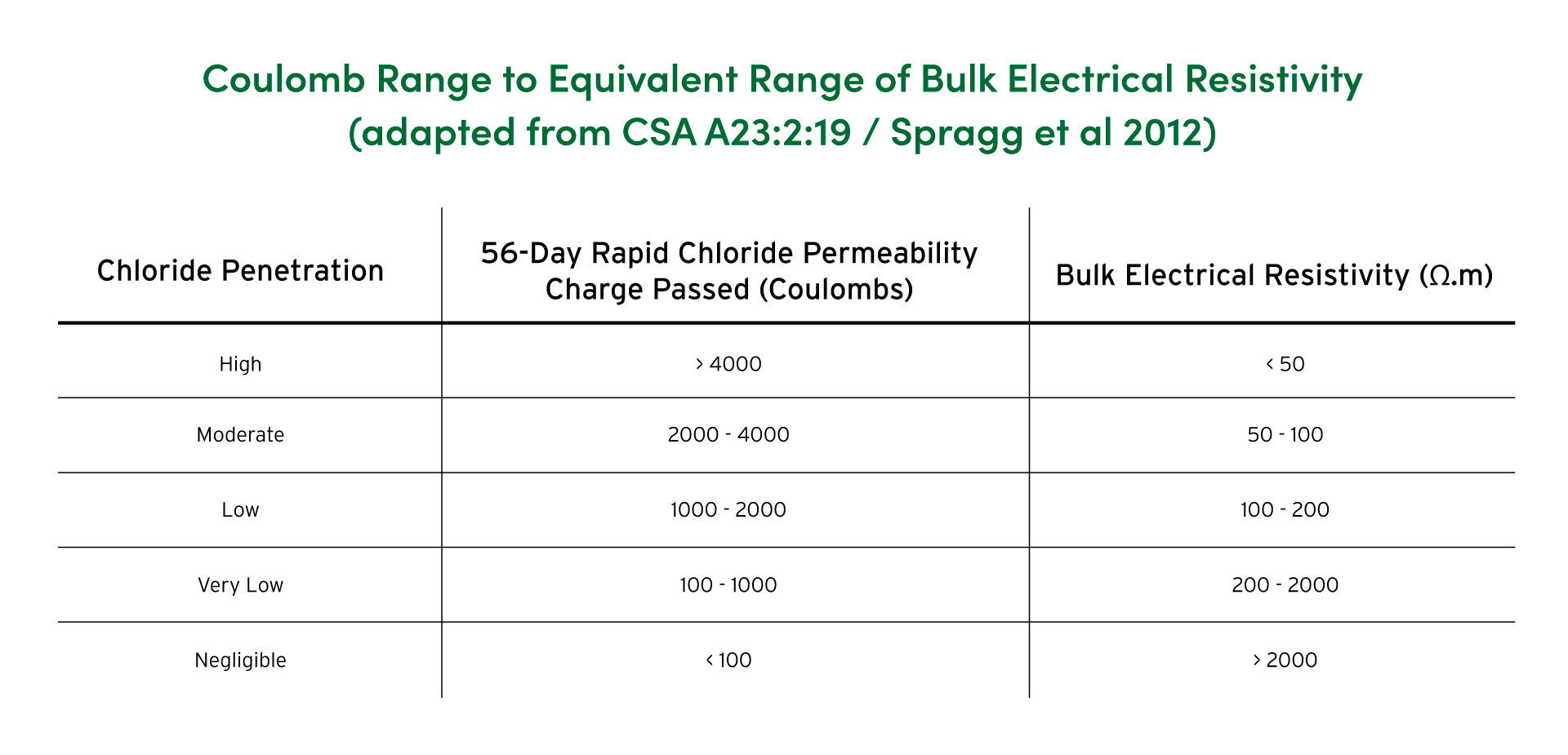

When strength is the only quality specification, contractors concentrate their efforts on delivering a material that is compliant with strength requirements. This ultimately does not represent the durability of the concrete. As a result, multiple tests for obtaining and understanding durability by measuring concrete’s ability to resist chloride penetration have widely become accepted. This method, commonly known as RCP, measures chloride penetration in a range from high to negligible. The “ASTM C1202: Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration” standardizes this process.

However, not only is this approach labor-intensive but also time-consuming. The test itself takes 6 hours to complete and it requires extensive sample preparation. This includes cutting and conditioning the samples into a desiccator for 3 hours, letting the specimens soak with water for 18 hours before the test, as well as many more steps. In addition, this test method is often very expensive due to the amount of work required to perform the analysis.

Electrical Resistivity Test

A much faster and less expensive method for determining the quality and durability of concrete is electrical resistivity. Evaluating concrete quality with electrical resistivity test can help engineers quickly assess the ability of concrete to resist a chloride passage or flow of electrical current. As a result, it evaluates the quality control and service life prediction of the concrete. There are two reasons for this:

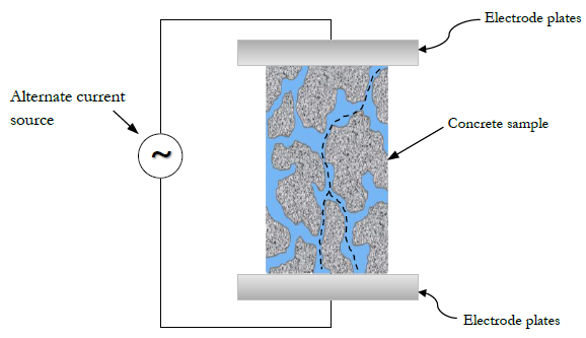

- First, when concrete is subject to an electric field, the current starts to move through the pores of the material. The ability to withstand this current transfer indicates resistivity.

- Second, the resistivity demonstrates the permeability of fluids throughout the concrete. Thus, it indicates how durable the concrete is. Especially as chloride penetration can cause corrosion of reinforcing steel.

Similar to strength, electrical resistivity is a property of any given concrete. Its main advantage is the ease of measurement and testing speed. Electrical resistivity has been used to measure concrete quality since the early 1910s. However, in recent years, modern devices have developed to improve this measurement process.

How Can a Concrete Resistivity Test Help the Construction Industry?

The durability of concrete is largely related to its microstructure, such as its porous network and interconnections. For instance, concrete with low porosity and interconnections has lower conductivity and thus lower permeability. In that sense, the idea behind electrical resistivity is to quantify the conductive properties of the concrete. This makes a direct comparison with the durability of the material.

Furthermore, electrical resistivity can be used for several applications, both in the lab and field. For instance, one can track changes in the mix design, such as alterations in cement or additions, by comparing resistivity values from lab specimens with field samples. Resistivity results can also be correlated to other characteristics, such as chloride diffusion coefficient, water absorption, and corrosion rate of rebar in reinforced structures. Those characteristics provide not only a quantitative assessment of concrete, but also general guidance on the current durability status of any given concrete element.

There are different ways to measure the electrical resistivity of concrete. The most common are bulk resistivity, surface resistivity, and embedded electrodes for fresh concrete. Giatec has built devices to measure the electrical resistivity of concrete based on these techniques:

- RCON: Laboratory Device for Testing Bulk Electrical Resistivity

- SURF: Laboratory Device for Testing the Surface Electrical Resistivity of Concrete

Bulk Resistivity

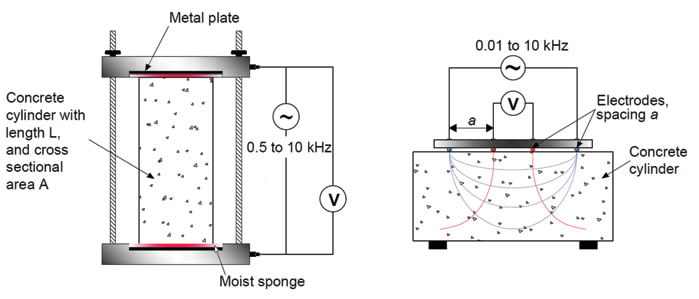

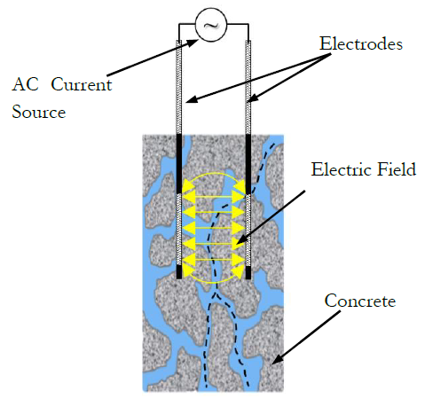

The bulk electrical resistivity test uses a two-point technique. This means that two electrodes are used to send and read the current flow in a concrete sample. In this method, a hardened concrete specimen is placed between two parallel electrode plates which transmit an alternate current (AC). The resistivity is calculated as an average of the entire material between the plates in a matter of seconds.

Governed by AASHTO TP 119: Standard Method of Test for Electrical Resistivity of a Concrete Cylinder Tested in a Uniaxial Resistance Test, the release of CSA A23.2-26C: Bulk electrical resistivity of concrete, and ASTM C1876-19: Standard Test Method for Bulk Electrical Resistivity or Bulk Conductivity of Concrete has brought even more relevancy to measuring bulk electrical resistivity of concrete.

As there is a correlation between bulk resistivity and the RCP test (refer to the table below), one can perform resistivity measurements to gather the durability status of the concrete. Since this test is completely non-destructive, it is also possible to perform a compressive strength test and obtain the compressive strength of the same sample.

Surface Resistivity

Generally, both the surface and the bulk electrical resistivity will deliver the same results as long as factors are taken into consideration. Surface is guided by AASHTO 358-19: Surface Resistivity Indication of Concrete’s Ability to Resist Chloride Ion Penetration. However, due to its high acceptance, there are current studies focusing on the standardization of this technique.

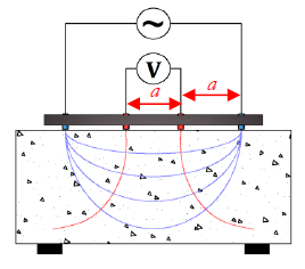

The method uses the Wenner-Array setup, where four electrodes are positioned in a straight line and equally spaced. The two outer electrodes send the current into the concrete, while the two inner electrodes measure the electrical potential. This approach allows the assessment of concrete samples and facilitates the evaluation process on job site conditions as local properties can be measured in a simple manner and requires almost no preparation.

Embedded Electrodes: Fresh Concrete

For electrical resistivity of fresh concrete, embedded electrodes can be used to track changes in the concrete hydration process. When the concrete hardens, there is an intrinsic reduction of moisture due to the hydration process. Therefore, the results of the electrical resistivity test will increase with the hydration process. In addition, the results acquired with this method allow the user to obtain parameters like water content, predict the setting time, and detect cracking.

Due to its high versatility and utility, more studies are being developed in this field. Currently, there have been efforts put in place to standardize this technique in the coming years.

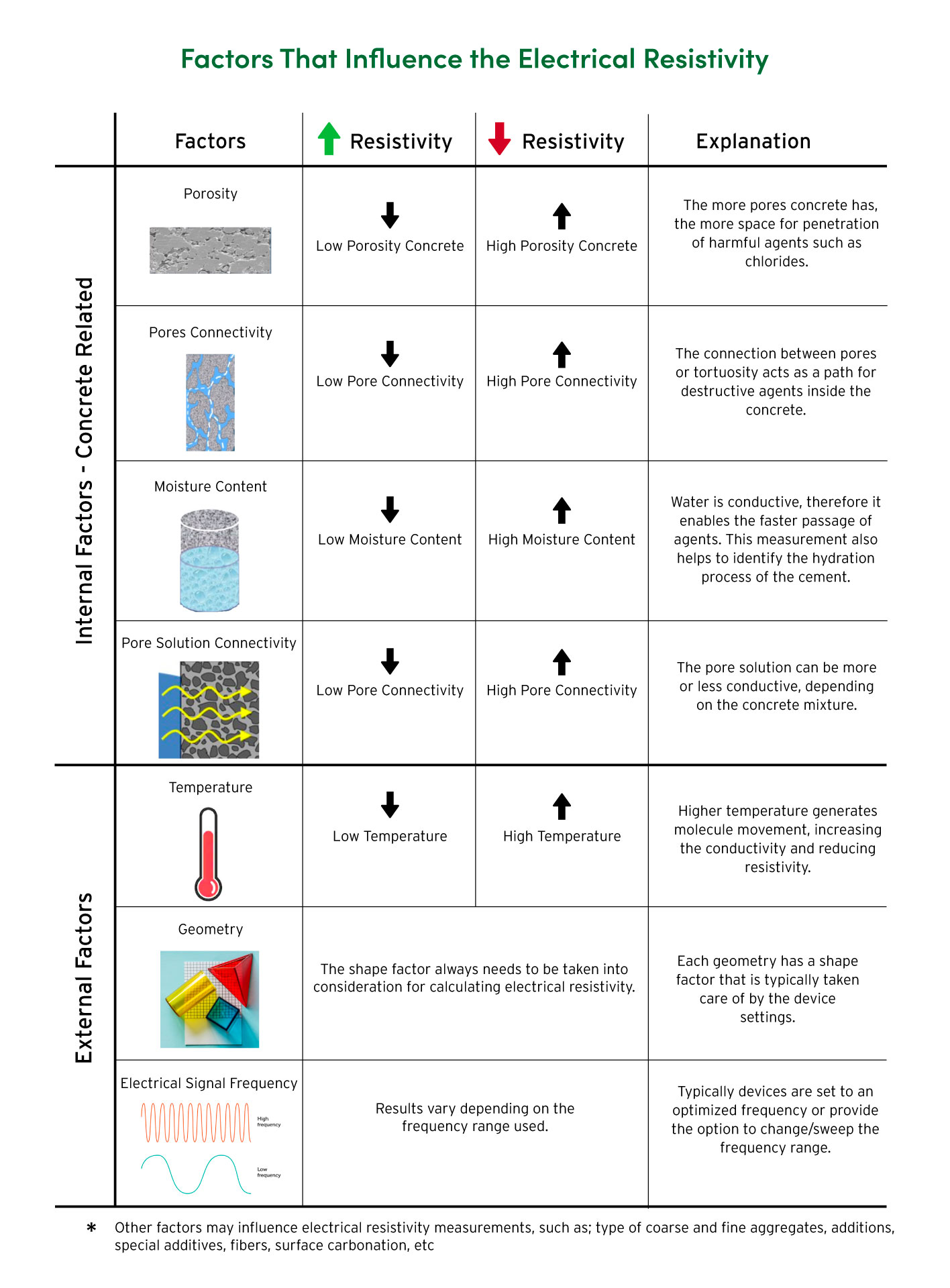

Factors that Influence Electrical Resistivity Measurements

Although an electrical resistivity test has the advantage of being easy and rapid to perform, there are key factors that can influence the results.

Electrical resistivity will continue to play an important role in the quality assessment of concrete. In fact, due to advantages, such as ease of use, fast results, and good correlation with durability properties, there are current studies to standardize electrical resistivity and its direct correlation in assessing the durability of concrete.

Interested in a more in-depth analysis of concrete resistivity? Read more here.

Ready to upgrade your lab testing? Discover how RCON delivers faster, more reliable resistivity measurements.

*Editors Note: This post was originally published in January 2020 and has been updated for accuracy and comprehensiveness in May 2023.