Wireless technology has been growing at an incredible rate, having a deeper presence in everyday life than ever before. From earbuds to refrigerators, it seems like everything is getting the wireless treatment these days to a point where you might ask, isn’t it a bit excessive? One of the biggest reasons for this push in connectivity is the need for efficient, easy, real-time data. Prompt and accurate information can greatly help in improving efficiency in every industry, construction jobsites being no exception. So, what is the value of real-time data and how can it increase efficiency on your construction jobsite?

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Data in the Construction Field

A jobsite has much to offer in terms of useful data that can measure both quality and progress. This data, however, brings its own set of challenges to the table. Current processes for collecting valuable information like concrete slab strength is tedious to obtain and requires off-site lab testing, often introducing long delays. Alternatively, wire setups around the workplace, such as thermocouples and data loggers for temperature monitoring, often result in hazards, like damaged wires. With no other alternatives at the time, the industry had accepted these as standard practices and continues to spend time and money into perpetuating these problems.

With construction already being expensive and the work dangerous, there is a significant benefit to push for efficiency on jobsites. Data collection should be done as easily as possible to optimize time, risks, and costs.

Learn more about the inaccuracies associated with concrete cylinder testing here.

Cloud Concrete Monitoring with Wireless Devices on the Jobsite

Wireless devices

Once gathered, this real-time data can be used for an endless number of benefits. From quicker problem response, accurate scheduling, resource management, reporting, and saving costs, to name a few.

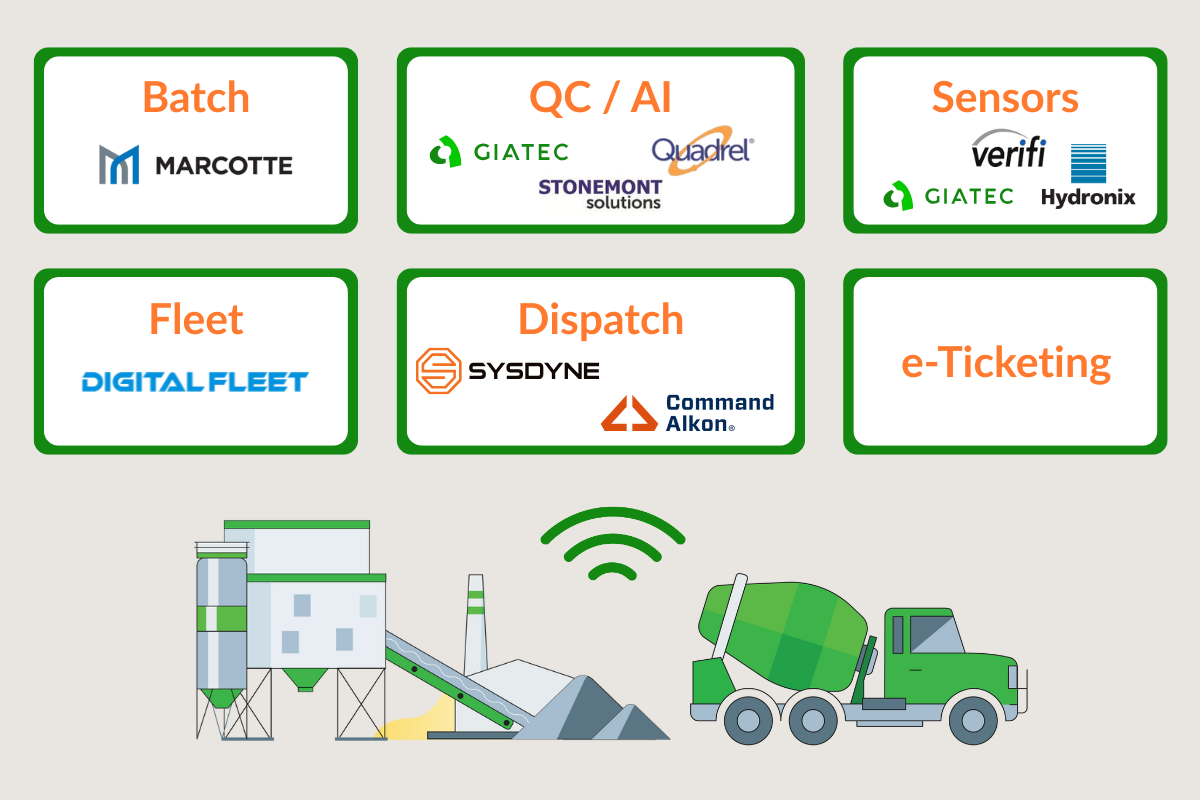

There are a few approaches cloud-connected sensors can use to communicate wirelessly:

- Sending data to existing infrastructures

- Adding an ‘in-between’ device to sensors and other infrastructure

- Connecting and collecting data manually

How Wireless Technology and Concrete Monitoring Apps Can Solve Your Onsite Problems

Option A: Sending Data Directly

Although sending data directly to existing infrastructures may seem like the simplest solution, current protocols make this difficult.

Individual devices will have problems with long distance communication, as current 3G / 4G / LTE requires a significant amount of power for transmission. Cellphones can easily accommodate the demands with expensive batteries and regular charging but not so much with the coin cell batteries expected to run many IoT networks. On the network side, the bandwidth of current generation cellular protocols will not be able to support the billions of devices predicted to join in the next half a decade.

Solutions like 5G, and NB-IoT, networks are being developed and slowly rolled out globally to tackle both sides of the issue. They are, however, still in their infancy as many of these protocols have only become active within the past few years and thus will need more time before they become commonplace.

Take a look at why the Internet of Things would benefit from having its own network.

Option B: Hubs for Network Access

Most IoT networks currently rely on a middle-man approach, with local gateways to manage the power demands of long-range communication. These devices work just like routers used for Wi-Fi at home, providing a more efficient way for wireless devices to exchange data.

A major advantage for these gateways comes from their design, often being tailored for the features and requirements of their network. Different connection protocols like cellular, Zigbee, and Wi-Fi can be integrated along with features such as more efficient power management, user configurations, and data reporting. An example gateway is the Giatec SmartHub™, which can be deployed in the field to gather data in real-time using an LTE or Wi-Fi connection to communicate with the cloud for off-site monitoring. The SmartHub connects with Giatec’s concrete monitoring app, SmartRock®, to send all your important data to the cloud, then to your mobile device.

Many challenges can come into play when designing gateways for different applications. Factors like; placement, communication protocols, and power management must be taken into careful consideration which can contribute to a lengthy development timeline. With some time, we will see this category flourish in the coming decade!

Option C: Connecting and Collecting Data with the SmartRock Concrete Monitoring App

Bearing in mind that low-power devices have great difficulty sending data long distances, and that gateways can sometimes be limited in availability, what is the current solution? Well luckily one of the best type of data collector can already be found in your pocket, on your desk, or in your hands right now: your phone!

Provided there are operators on-site to connect to devices, a phone is a great tool when it comes to wireless communication, having LTE and Wi-fi radios already integrated. Applications, like the Giatec SmartRock app, can be quickly installed for free. SmartRock collects temperature and strength information from the sensors without the need for additional hardware, providing analysis and reports immediately upon connection.

Information, no matter the industry, will forever be relevant in improving the workplace. With wireless systems and sensors, it is now easier than ever to collect real-time data to provide faster, safer, and more economic services. With construction being as big a field as it is, especially with new projects constantly popping up, the data that we can collect provides a better understanding on what we can improve to ultimately make jobsites more efficient workplace.

**Editor’s Note: This post was originally published on July 3, 2020 and has been updated for accuracy and comprehensiveness.