What Is the Thermal Modeling Feature?

Thermal Modeling is Giatec 360™’s first-of-its-kind new feature that can be used to predict concrete temperature in a mass concrete element. When constructing mass concrete elements, limiting peak temperatures and temperature differentials within the concrete is extremely important. This helps to limit the potential of long-term and short-term cracking and increases the concrete’s quality and long-term durability.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Be fully prepared for your next mass concrete project!

Designing and planning for mass concrete pours can be a very challenging task. One must consider different elements such as changing weather and adjustable design items such as the concrete mix, the concrete delivery temperature, the type of protection system, the length of protection, etc. The thermal modeling feature allows users to experiment with these elements to help build thermal control plans (TCP). It also provides insights on daily adjustments to upcoming pours by outlining the temperature of the concrete at various defined depths, the expected maximum temperature, and the temperature differential.

How Does It Work?

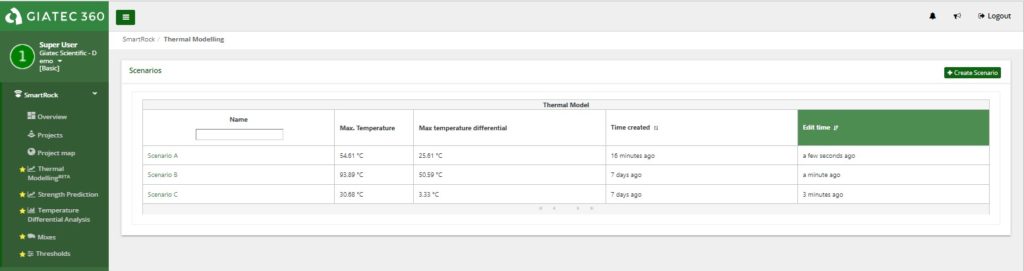

The thermal modeling feature is intuitive, user friendly, and it does not require any specialized training. The 3 steps listed below can be followed by any user to create a thermal modeling scenario and get a predicted temperature and temperature differential profile in a matter of minutes.

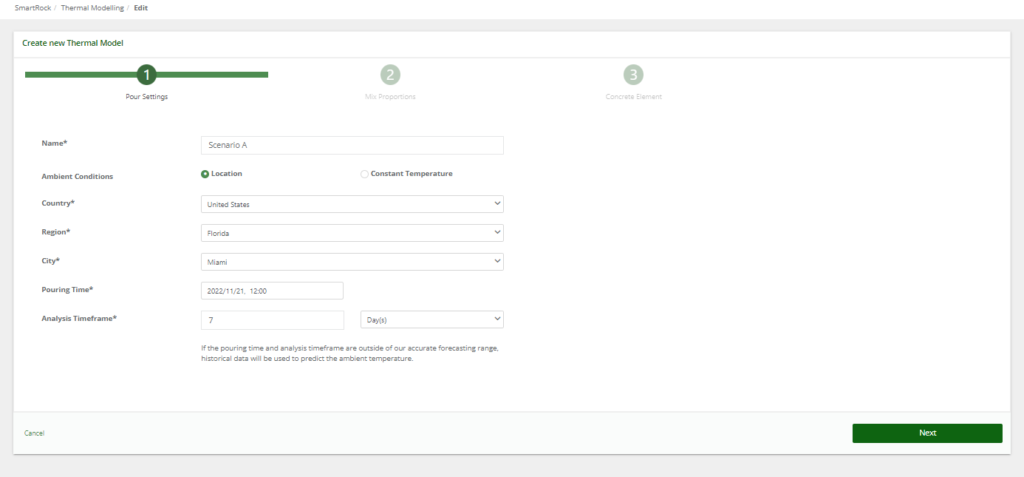

Step 1: Pour Settings

The first step is generating a scenario. The user will be required to come up with a name, identify the location of the pour, and set a time and duration of the analysis. Alternatively, users will have the option to specify constant temperature and humidity levels if they choose not to use the weather forecast method.

Step 2: Concrete Mix Design

The concrete hydration and temperature behaviour largely depend on the concrete mixture proportions and material type. Therefore, the second step in the thermal modeling analysis is specifying mix proportions.

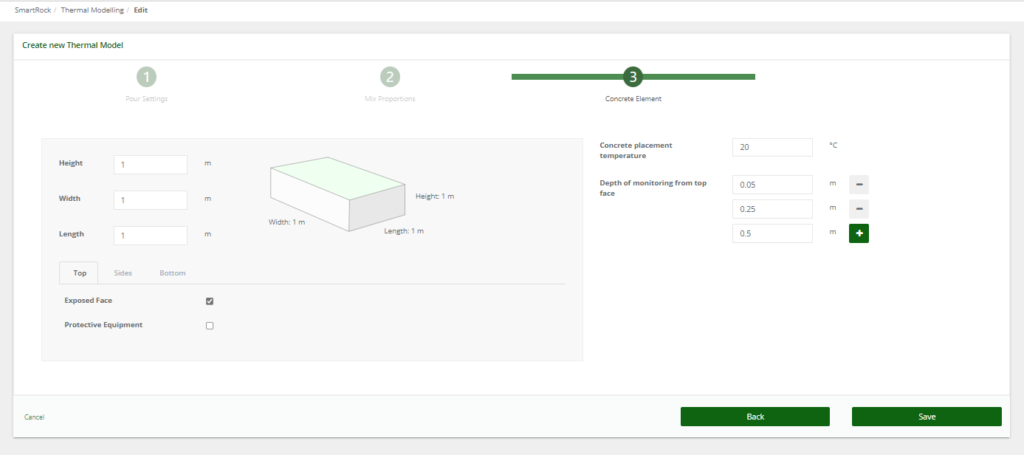

Step 3: Concrete Element Design

The final step is defining the concrete element dimension and its boundary conditions. In other words, users can specify the dimensions of their concrete element as well as the protective equipment (or lack thereof). This type of protective equipment is important as it alters the surface temperature of concrete which largely impacts the temperature differential. The thermal model can help users determine what type of protective equipment (if any) is necessary, and when it can be removed.

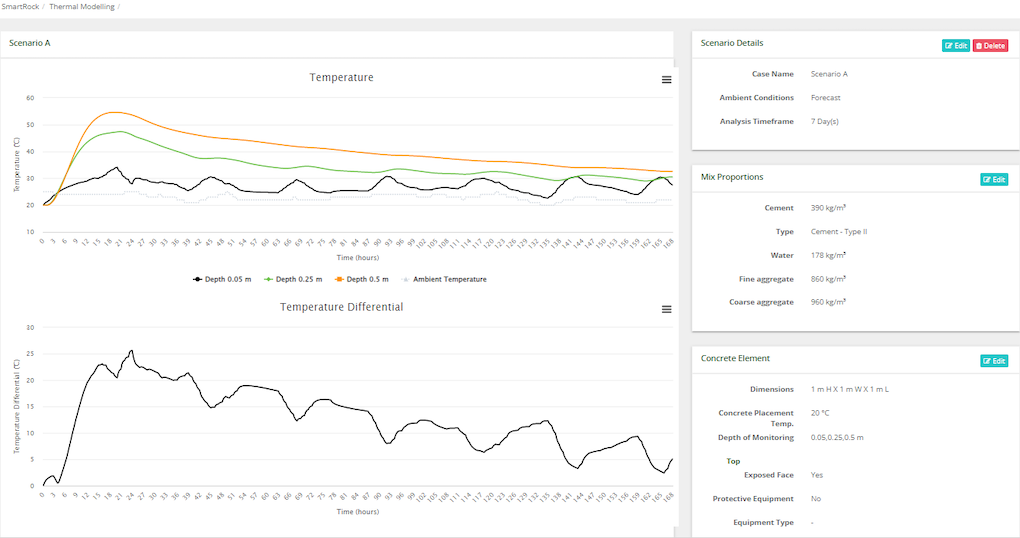

In this step, users can indicate the depth values at which they would like to collect temperature measurements and the flexibility to change the pouring concrete temperature. The feature delivers a temperature graph showing the ambient temperature and the progression of temperature at all the specified depths over the analysis time specified. This helps to calculate the temperature differential. Additionally, users can go back and modify some of their inputs or save the scenario for future reference.

What Are the Advantages of Thermal Modeling?

Thermal modeling is a comprehensive solution that brings value to engineers, general contractors, and ready-mix producers.

Optimized planning

The feature can generate various scenarios daily, allowing contractors to make quick and informed decisions. These include determining optimal pouring time, the type of protective equipment (if any) to use, the best moment to remove said protective equipment, and how to adjust mixes and protection for upcoming pours. The freedom to validate inputs with weather forecasts enables contractors to validate important decisions and makes it easier for them to manage their upcoming pours.

Validate how much cooling is needed for pouring temperature requirements

Adjusting the amount of ice, liquid nitrogen or other cooling methods required to lower down the initial temperature can be expensive. By iterating the initial concrete temperature users will gain valuable insight into how much colling of the concrete mix is required to maintain the maximum temperature within set limits.

On the fly mix design changes or alternative options to still meet temperature requirements

Often, mix designs need to be changed at the last minute because of unexpected situations, such as the low supply of a material or changes in its properties. This feature allows users to do validation testing on the fly and understand if any adjustments are needed to proceed with the pour.

Help to build thermal control plans

Many different scenarios can be created to account for different ambient conditions or possible limitations during the duration of the project. Thermal Modeling helps the user identify scenarios where additional protection or cooling would be necessary. And while Thermal Modeling does not replace thermal control plans, we recommend using this feature in conjunction with your TCP to get a more comprehensive idea of the temperature profile in your mass concrete element.

Unlimited mix design iteration without physical testing

Users can experiment with different concrete mix designs to find which one performs better under their defined conditions. This reduces the need for physical tests, especially during the design phase and the making of thermal control plans.

Time and cost savings

Generating scenarios within 5 minutes not only reduces the need for physical experiments, but it also optimizes the use of resources. Users can lower labour and material expenses while saving precious time.

User control insights

Users have complete control over the information they want to confirm as they can create and edit numerous scenarios with varying inputs. The resulting outputs give the user invaluable insights, which can be interpreted to understand how to achieve desired outcomes and the appropriate safety measures.

No expensive modeling or complex DYI computation

Unlike most thermal control plan solutions currently available, Giatec 360’s Thermal Modeling feature is exceptionally user-friendly and intuitive, requiring no specialized knowledge and training to operate. Users will not have to perform any complex calculations, involve expensive and hard-to-use FEM or FEA, or analyze complex spreadsheets.

Follows ACI 207.2R calculation guidelines

The thermal modeling tool adheres to the ACI 207.2R’s guidelines and creates reliable scenarios for users to review.

Learn more about this and other features for monitoring and managing concrete pours with Giatec 360, a web-based dashboard that showcases data analytics, reports, and user management capabilities for SmartRock® sensors.