Mass concrete refers to large-scale concrete structures that require careful attention to heat generation and temperature control during curing due to the significant volume of material involved. Mass concrete is commonly used in infrastructure projects such as high-rise buildings, dams, bridges, and power plants. It takes advantage of its wide availability of raw materials, excellent mechanical properties, durability, low cost, and ease of construction. However, due to the large size of mass concrete elements, managing temperature-related issues becomes crucial.

Big Projects Deserve Better Protection

What Causes Concrete Cracks?

Before addressing the cracking issue in mass concrete, it’s essential to understand the underlying causes and factors contributing to these cracks. Understanding heat generation and dissipation is crucial for ensuring structural integrity, as the exothermic hydration reaction of cement produces heat that can create significant temperature differentials within the structure.

Key factors influencing heat generation include cement type, composition, fineness, and mixture proportions, alongside variables like placement dimensions, cementitious materials, formwork, insulation, and ambient conditions. Mass concrete elements encounter challenges in heat dissipation due to their thermal properties, which hinder heat loss. Larger structures can experience higher hydration peaks and extreme internal temperatures, particularly in the core, where adiabatic conditions may trap heat. For instance, cores can take days or even years to stabilize thermally, as seen in monumental projects like the Hoover Dam, which can require up to 200 years for cooling.

Cement Hydration

The hydration of cement progresses through five stages: Pre-Induction, characterized by rapid temperature rise upon water contact; the Dormant Period, where hydration slows due to diffusion barriers; two Strength Gain stages, during which concrete hardens over hours to days; and the Steady State stage, where temperature stabilizes with the ambient environment while hydration continues.

Thermal Gradients

The temperature difference between the interior and exterior of the concrete leads to thermal gradients, which cause thermal stress. If this stress exceeds the tensile strength of the concrete, cracks can form. These cracks not only compromise structural safety but also reduce the durability and lifespan of the structure. In addition to thermal stress, cracks in mass concrete can also result from shrinkage due to water evaporation and other factors. Modern construction methods demand concrete with high flowability, which often requires a higher water-cement ratio. As the free water evaporates during curing and in use, the concrete experiences shrinkage, leading to additional cracking.

Common Types of Concrete Cracks

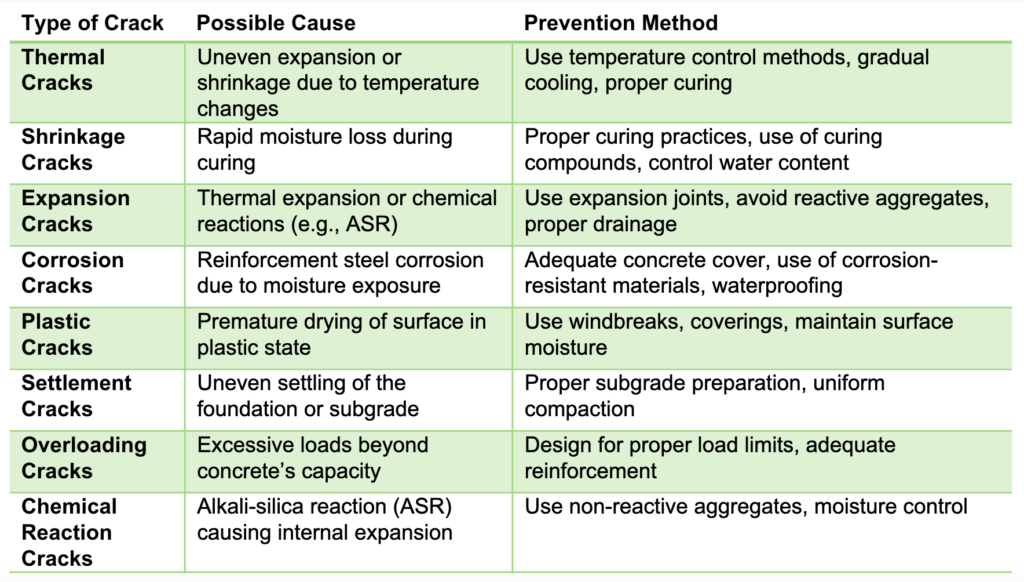

To prevent or reduce cracks caused by both thermal stress and shrinkage temperature control measures are critical. The table below summarizes common types of concrete cracks, their potential causes, and effective prevention methods.

For more information about the thermal cracking, you may refer to our blog. Click here!

Key Methods for Managing Temperature in Mass Concrete

As discussed earlier, managing mass concrete temperature is essential to prevent thermal cracking from cement hydration heat. Here’s how to control it:

1. Understanding Heat of Hydration

During the chemical reaction between water and cement, known as hydration, heat is released. This heat can accumulate in large masses of concrete, raising internal temperatures. If the core of the concrete becomes much hotter than its surface, it can lead to internal stress and cracking. Monitoring this process is essential for temperature management.

2. Sensor-Based Monitoring

Installing temperature sensors in the concrete at different depths allows for real-time monitoring of temperature variations. These sensors provide precise data on both the core and surface temperatures. This technology enables:

- Early Detection: Identifying hot spots and potential thermal gradients before they become problematic.

- Accurate Adjustments: Based on sensor data, cooling techniques or insulation can be adjusted to manage the internal temperature, ensuring optimal curing conditions and minimizing the risk of cracking.

- Using Sensors for Enhanced Monitoring: Giatec’s SmartRock® sensors offer a modern, efficient solution to mass concrete temperature management. By embedding these sensors, the internal conditions of concrete are continuously monitored, enabling early detection of potential issues such as temperature variations that could lead to cracking. SmartRock sensors go beyond traditional manual monitoring by providing real-time data, automatic alerts, and precise insights, allowing engineers to adjust cooling or insulation measures without delay. This proactive approach helps in achieving optimal curing conditions and reduces the risks associated with manual temperature checks, making it an indispensable tool for complex mass concrete projects.

- Enhanced Quality Control and Precision

Traditional manual methods often miss thermal variations or require labor-intensive monitoring efforts. With SmartRock, data collection is automated and more accurate, reducing human error and providing contractors with precise insights into concrete curing conditions. This advantage not only ensures quality control but also saves time and costs associated with managing mass concrete elements.

3. Pre-cooling Techniques

To reduce the initial temperature of the concrete, cooling the ingredients—such as using chilled water or ice before mixing can effectively lower the starting temperature. This decreases the peak temperature the concrete will reach during curing.

4. Post-cooling With Embedded Cooling Pipes

Once the concrete is placed, cooling pipes embedded within the mass can circulate cold water to remove excess heat, especially from the core. This technique can help regulate temperature over time, preventing the core from overheating and reducing the risk of large temperature differentials between the core and surface.

5. Temperature Control Through Construction Practices

Careful planning of construction activities is crucial. This includes scheduling placements during cooler periods, using insulating blankets or formwork to control heat loss from the surface, and sequencing concrete placements to avoid creating excessive thermal gradients across different sections.

Read our blog with detailed information on the types of concrete cracks and their causes.

Conclusion

In conclusion, preventing cracks in mass concrete requires effective temperature management during curing, as heat from cement hydration can cause thermal stresses. Important tips include pre-cooling concrete, monitoring with sensors like SmartRock, post-cooling with embedded pipes, and maintaining consistent surface temperatures. By leveraging sensor technology, construction professionals can ensure better quality control and timely adjustments and ultimately extend mass concrete projects’ durability and structural integrity.