In concrete production, the truck does not simply serve as a means of transportation. The mixer plays a key role in the manufacturing process, functioning as a “factory on wheels”. Each truckload is carefully batched to meet project specifications, but the outcome depends on managing several variables in transit. One of the most critical yet often misunderstood components is the slump–a measure of concrete’s consistency and workability. In this blog, we’ll explore why accurate slump measurements are crucial, the challenges associated with maintaining slump, and how improving visibility and control during the process can be the competitive advantage needed.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

What is a Slump Test?

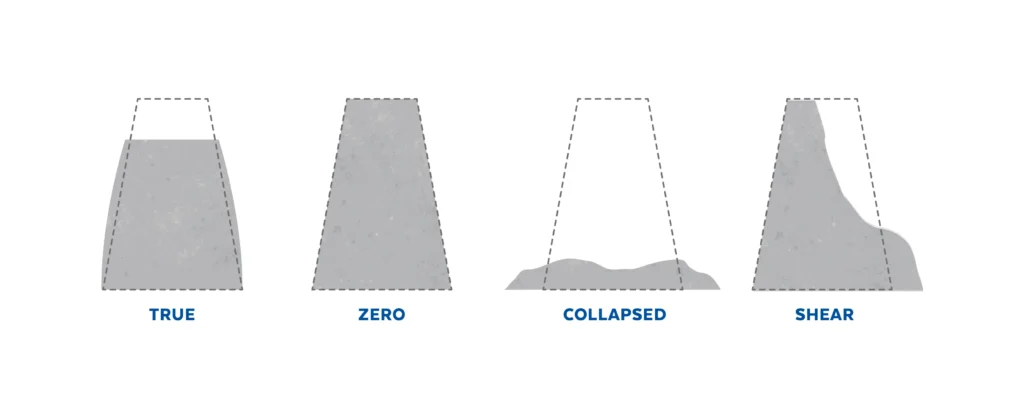

A slump test is conducted to measure the consistency and workability of fresh concrete. Often conducted by a third party, this test evaluates whether concrete meets the required specifications for a particular project. Depending on the job size, slump tests are performed anywhere from every 8 to 50 cubic yards.

However, the fast pace of concrete delivery and pouring often prevents proper testing. This makes slump tests reliant on subjective methods through instinct and visual estimation, resulting in inconsistencies and errors. This caliber of testing does not only impact the load being tested, it impacts quality from plant to pour. Leading to wasted time, resources, and materials throughout the entire manufacturing process.

Overcoming Common Challenges

Ensuring an accurate slump is only one piece of the puzzle. Concrete truck drivers must navigate a range of challenges that arise during transit:

- Temperature Control: Concrete temperature directly affects curing times. If the temperature gets too high, it accelerates curing, and as a result reduces workability. On the other hand, if the temperature is too low, setting times are delayed. Hence, optimal temperature control is essential to ensure workability and the desired setting time.

- Mix Homogeneity: Continuous mixing in the truck’s drum ensures that the concrete remains uniform. Without this, the mix can separate, leading to inconsistencies that compromise the final product.

- Transit Time: Most ready-mix concrete has a transit time window to 60 to 90 minutes. During this time, the concrete continues to mix, which affects both curing and workability. Exceeding this window increases the likelihood of rejected loads.

- Drum Rotation Speed: The drum’s rotation speed is also a critical factor. If it rotates too slowly, the concrete may begin to set or segregate. However, if it rotates too quickly, excessive air may be introduced, leading to a loss of workability and strength.

The Impact of Inaccurate Slump

The challenges of maintaining slump are not just operational hurdles–they have significant implications for project outcomes. When slump is not accurately managed, the consequences can be far-reaching:

- Rejected Loads: Loads that don’t meet project specifications can result in both costly delays and wasted material.

- Workability & Setting Time Issues: Variability in slump affects the ease of placement and the time required for the concrete to set.

- Inconsistent Data: Producers need reliable, real-time data to fine-tune their mix designs and ensure performance goals are met.

- Driver Involvement: Relying too heavily on drivers to adjust slump in transit adds complexity and increases the margin for error.

- Increased Liability: Inconsistent slump introduces risks that can compromise structural integrity and lead to disputes.

The Power of Real-Time Data

Addressing these challenges requires advanced systems that provide real-time visibility into slump and other critical factors during transit. Current systems, while effective in many respects, often face limitations due to the calibration required and the lack of seamless data flow. These solutions typically struggle to provide continuous, real-time data, leading to potential delays and inconsistencies.

While slump measurement remains a challenge, tools like SmartRock® Pro provide a modern solution for ensuring concrete quality by offering real-time data on critical factors such as temperature and strength with no calibrations required. Unlike traditional systems that require time-consuming calibrations, SmartRock Pro is fully self-calibrating, eliminating this complexity and ensuring seamless operation. While it doesn’t directly measure slump, the insights from SmartRock Pro help producers monitor and better understand mix behavior over time. This allows for precise adjustments to maintain optimal workability and strength, ensuring each mix meets performance requirements without compromising durability.

With more advanced technologies on the horizon, producers can look forward to improved control over their operations, reduced reliance on manual interventions, and the ability to proactively prevent issues before they arise. Accurate slump measurement is not just a technical requirement–it is the foundation for ensuring quality, efficiency, and trust in every load delivered.

Curious to explore Giatec’s other innovative solutions? Discover our range of products designed to revolutionize the concrete industry!