Does your company provide condition assessment services to your clients? When was the last time your customers understood the corrosion levels on the surface of their reinforcement? Conduct annual and even semi-annual testing to understand the condition of the rebar over time. Then estimate the remaining service life. Take your client satisfaction to the next level! Expand your condition assessment services today with the award-winning corrosion assessment tool called the iCOR®.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

What Is Concrete Corrosion and Why Is It a Problem?

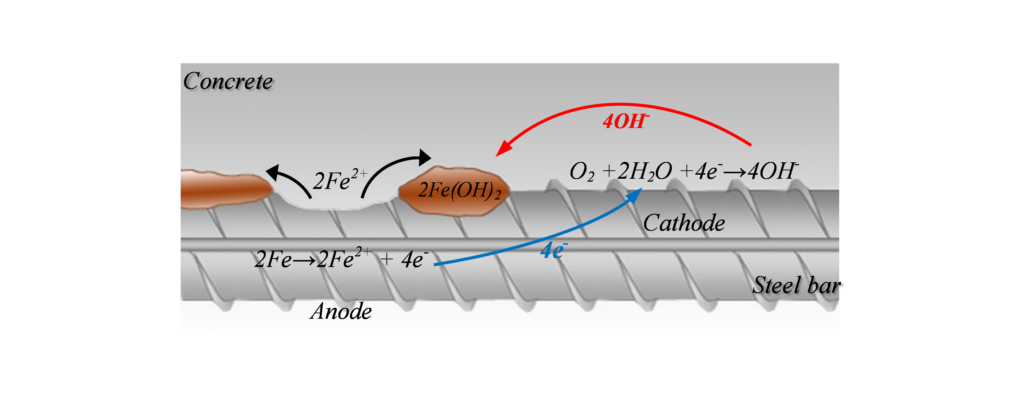

Corrosion begins when harmful materials, such as CO2 and chloride from de-icing salt, penetrate the concrete and reach the steel reinforcement. As an electrochemical reaction, electrons migrate from the anodic zone to the cathodic zone. They release ferrous ions at the anode and hydroxide ions at the cathode. This will eventually lead to a potential difference between the anodic and cathodic areas at the surface of the steel reinforcement. This results in the creation of rust as a by-product. Since rust occupies a larger volume than steel, it exerts internal pressure. This causes the surrounding concrete to crack and become damaged. These cracks make their way to the surface of the concrete. This causes even more CO2 and chloride to penetrate the concrete which speeds up the process of corrosion.

Test reinforced concrete structures annually or even semi-annually to detect and prevent corrosion using a good-quality corrosion assessment tool. As these structures get older, the risk of corrosion in reinforcing steel continues to increase. This is especially important because many structures were built using reinforced concrete between the 1950s and 1970s. Consequently, these structures require more frequent testing and repairs to eliminate damage and slow down the corrosion process.

Assessing Rebar Corrosion in Concrete Structures

How are your clients currently monitoring corrosion in reinforced concrete? Does it involve drilling a hole in their structure? Sticking a probe in? Or maybe using a logger to collect data that needs to be analyzed offsite? This process takes days and even weeks just to measure concrete corrosion in ONE structure. Often, people discover the damage too late to repair it. Destructive techniques not only consume time but also damage the overall structural integrity. Especially if the concrete is not repaired properly.

Do you offer your customers alternative methods of testing rebar corrosion? Your customers can detect damage early and predict the rate of future deterioration of their structures in seconds. They can achieve this using Giatec’s corrosion assessment tool, iCOR®. This tool features patented Connectionless Electrical Pulse Response Analysis (CEPRA) technology.

What is iCOR? Giatec’s Non-destructive Concrete Corrosion Monitoring

The iCOR, a non-destructive corrosion assessment tool, is an award-winning device recognized for its positive impact in corrosion monitoring and mitigation. Using our patented CEPRA technology, the device is unique in its ability to perform three-in-one concrete testing measurements of: rebar corrosion rate, half-cell potential, and in-situ electrical resistivity.

Why Select the iCOR as Your Corrosion Assessment Tool

- Award-winning technology: This award-winning device received the 2019 Corrosion Innovation of the Year Award from the National Association of Corrosion Engineers (NACE).

- No connection to the rebar required: Unlike other corrosion assessment tools available, iCOR is a wireless non-destructive testing (NDT) device that does not require a connection to the reinforcement for measuring corrosion rate and resistivity, making it extremely convenient for monitoring the health of reinforced concrete structures.

- Comprehensive condition assessment of concrete: This device allows engineers to fully understand concrete quality and rebar corrosion activity, helping them make timely decisions regarding the rehabilitation and repair of their structures.

- No waiting periods between measurements: The iCOR uses a current pulse when polarizing reinforcements in minimal time between performing measurements. This means you can collect data over the same location without having to wait hours between readings for the reinforcement to depolarize, unlike other techniques.

- Fast and easy to use: Incorporating iCOR is fast and easy. Use its user-friendly interface and data analysis software with minimal training.

- User-friendly app: The iCOR device sends data directly to your tablet via an app in the field, allowing easy storage, analysis, and sharing with team members.

- Time savings and cost reduction: Getting all three measurements with one device significantly save time, costs, and resources associated with the condition assessment of reinforced concrete structures.

Read more about how iCOR compares to other methods of monitoring concrete corrosion

Improve Your Corrosion Assessment Client Services with iCOR

For all these reasons, the iCOR is the most convenient corrosion assessment tool measurement device in the field. Not only does it gives engineers a comprehensive understanding of concrete quality and the level of corrosion; ultimately, it allows them to make faster, more informed decisions when it comes to rehabilitation and repair and estimation of service-life. Offering corrosion assessment to your clients using this ground-breaking device would allow you to stand out from your competition by providing the most sophisticated solution for them to assess corrosion. It will allow your customers to better understand the health of their structures.

4 Responses

I would like to receive real case studies on using iCOR

Hi Sami, please check out our iCOR product page. In the download section at the end you can see some of our iCOR case studies. https://www.giatecscientific.com/products/concrete-ndt-devices/icor-rebar-corrosion-rate/

Thanks for this great email

Actually we have iCOR and we are about to use it in one of our structural assessment studiesso can you please send us one or two cases showing the method and results of corrosion rate and potential in RC structures.. Best regards

Hi Sami, please check out our iCOR product page. In the download section at the end you can see some of our iCOR case studies. https://www.giatecscientific.com/products/concrete-ndt-devices/icor-rebar-corrosion-rate/