Achieving high-performance concrete requires careful consideration of mixture proportions. In Türkiye, where construction projects demand both durability and strength, optimizing these proportions is crucial. In this blog, let’s explore the best practices for determining mixture proportions to reach desired concrete properties in Turkish construction projects.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Importance of Mixture Proportions

The mixture proportions of concrete significantly influence its performance characteristics, including strength, durability, workability, and resistance to environmental factors. Properly optimized mixture proportions ensure that the concrete meets the specific requirements of different construction projects, from residential buildings to large infrastructure developments.

Learn how Trio Ready-Mix transformed their concrete operations by optimizing their concrete mix!

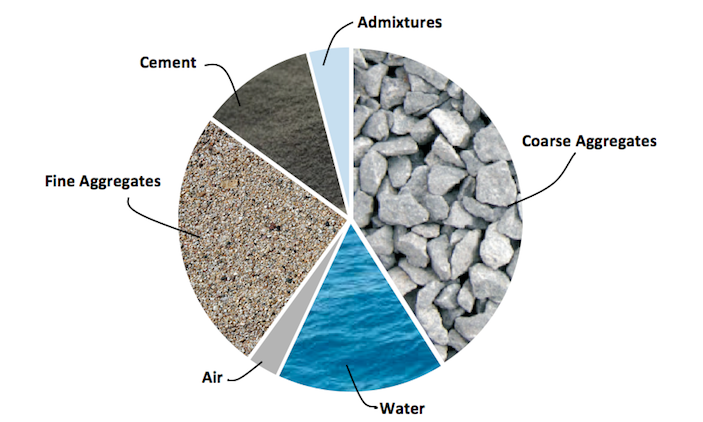

Key Components of Concrete Mix

Concrete is composed of four main components: cement, aggregates, water, and admixtures. Each component plays a vital role in determining the properties of the final mix.

- Cement: Acts as the binding agent that holds the aggregates together. The type and amount of cement used can affect the strength and setting time of the concrete.

- Aggregates: Include coarse aggregates (gravel or crushed stone) and fine aggregates (sand). The size, shape, and quality of aggregates influence the concrete’s strength and durability.

- Water: Essential for the hydration process, which allows the cement to harden and gain strength. The water-cement ratio is a critical factor in determining the concrete’s workability and strength.

- Admixtures: Chemical additives that enhance specific properties of the concrete, such as workability, setting time, and resistance to environmental conditions.

Best Practices for Optimizing Mixture Proportions

- Determine Project Requirements: Before optimizing the mixture proportions, it is essential to understand the specific requirements of the project. Consider factors such as the desired strength, durability, workability, and exposure conditions. For example, a high-rise building may require a different mix than a bridge or an industrial floor.

- Select Quality Materials: Using high-quality materials is crucial for achieving high-performance concrete. Choose cement with appropriate strength and setting characteristics, and select aggregates that are clean, well-graded, and free from impurities. The quality of water used in the mix should also be considered, as impurities can affect the hydration process.

- Optimize the Water-Cement Ratio: The water-cement ratio is one of the most critical factors in concrete mix design. A lower water-cement ratio generally leads to higher strength and durability but may reduce workability. Conversely, a higher water-cement ratio improves workability but can compromise strength. Striking the right balance is key to optimizing the mix.

- Use Admixtures Wisely: Admixtures can significantly enhance the properties of concrete. For example, superplasticizers can improve workability without increasing the water content, while retarders can delay the setting time in hot weather conditions. Select admixtures based on the specific needs of the project and follow the manufacturer’s recommendations for dosage.

- Conduct Trial Mixes: Conducting trial mixes is an essential step in optimizing mixture proportions. By testing different mix designs, you can evaluate the performance of the concrete and make necessary adjustments. Consider factors such as slump, compressive strength, and durability when assessing the trial mixes.

- Monitor and Adjust: Once the optimal mix design is determined, it is important to monitor the concrete’s performance during construction. Regular testing and quality control measures can help identify any issues and allow for adjustments to be made as needed.

Interested in learning how you can optimize your concrete mix with AI? Check out our podcast on Giatec® SmartMix™!

Conclusion

Optimizing mixture proportions is crucial for achieving high-performance concrete in Türkiye. By following best practices and using quality materials, builders can ensure that their concrete structures meet the desired performance standards.