Most countries are embarking on a journey to reduce construction costs significantly. For instance, the UK government has set goals to reduce construction costs by 33%, accelerate project delivery, and lower greenhouse gas emissions by 50% [1]. Similarly, countries like Japan and the United States are working to reduce construction costs significantly. This underscores the necessity for futuristic engineering infrastructures. This is to withstand increasingly complex loads and integrate innovative technologies and streamlined processes. Structural design must now employ large foundation systems. They can be concrete rafts and piles using high-strength materials and innovative concrete mix designs to withstand excessive loads. Therefore, the primary objective is substantial cost reduction and swift delivery of infrastructures without compromising quality and sustainability. In this blog, we discuss the promising benefits of performance-based temperature differential limits as an effective solution for mass concrete construction.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

What Is the Role of Mass Concrete in Construction?

Mass concrete foundations offer a solution that balances the demands of urban development with environmental sustainability. They do so by using locally sourced materials, implementing efficient construction techniques, and prioritizing long-term durability. Historically, mass concrete has been used in dams, as it exhibits excellent durability and strength. These are essential properties for withstanding the immense hydrostatic pressure from large bodies of water. In recent years, contractors have used mass concrete in buildings and other infrastructural projects more often. For example, the advocacy for sustainable renewable energy, such as wind turbines, has increased the need for mass concrete foundations to support them.

However, one significant issue with mass concrete is heat generation during the curing stage, which can lead to significant thermal differentials within the structure. If not properly managed, these differentials can result in thermal stress-induced cracking, compromising the integrity and durability of the concrete. In order to reduce the heat of hydration of concrete during the curing stage, one can lower the tricalcium silicate (C3S) component of cement mainly responsible for early strength development. In some cases, supplementary cementitious materials are used to replace the cement content and mitigate the heat rise in the mass concrete element. Therefore, most mass concrete gains strength at a slow rate, resulting in extended project duration, high labor cost, and, in turn, high project cost.

Thermally Controlled Mass Concrete

To adhere to the goals of enhancing construction methodologies and advancing smart infrastructure, it is imperative that mass concrete foundation elements are engineered with rapid strength to gain concrete while also adhering to prescribed limits for maximum temperature and thermal differentials to ensure the integrity of the structure. ACI PRC 207.1-21 [2] classified mass concrete as thermally controlled mass concrete and traditional mass concrete. Thermally controlled mass concrete is potentially rapid-gain and high-strength concrete with a high risk of thermal cracking due to temperature buildup. While traditional mass concrete used in dams has slower gain and lower strength with lower temperature build-up. The thermally controlled mass concrete seems to align with the earlier construction objectives. However, the issue with the high concentration of cementitious materials can result in massive temperature build-up. This can potentially make it difficult to comply with statutory temperature differential requirements.

What Are Performance-Based Temperature Limits?

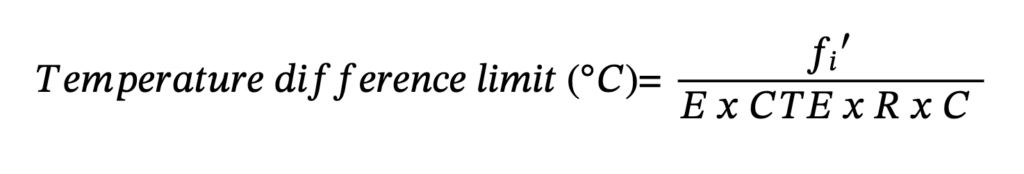

The concept of a performance-based temperature limit for mass concrete, as advocated by ACI 207, represents a proactive approach to address the challenges associated with temperature differences with the mass element. Rather than prescribing a static temperature difference of 20°C between surface and core, this approach emphasizes evaluating concrete’s performance based on certain mechanical properties. This allows for greater flexibility in design and construction while ensuring that the concrete’s performance meets the desired criteria. It is a known fact that the performance of concrete is a function of its mechanical properties like compressive and tensile strength, etc. The performance-based approach uses these parameters to determine the temperature difference limit of the mass element, as presented below.

Where:

- 𝑓𝑖′ = Tensile strength (MPa)

- CTE = Coefficient of thermal expansion (mm/mm/°C)

- E = Modulus of elasticity (MPa)

- R = Degree of restraint

- C = Creep factor

A detailed investigation by Al-Hasani [3] confirms that this performance-based temperature difference limit using the equation presented above was able to raise the temperature difference limit of a Portland cement (PC) mix and a partial replacement of PC with fly ash on a given mix from the static temperature difference limit of 20 to 52°C and 45°C, respectively. Also, she explains that the accurate value of the performance-based temperature differential limit of any mass concrete is a function of the correct assumption of the input parameters. So, obtaining an accurate limit value at various locations in the mass element in any period could be stringent. It is crucial to make this approach less rigid to facilitate its seamless adoption in the field.

Simplifying Performance-Based Temperature Limits

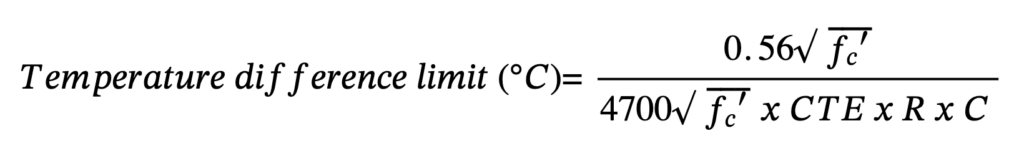

Concrete maturity offers a dynamic approach to monitoring concrete strength development over time from the curing temperature of the concrete. Using established relationships between concrete compressive strength, modulus of elasticity, and tensile strength, the temperature difference limit can be rewritten as follows:

We can obtain the performance-based temperature limit by obtaining the in-situ compressive strength. Also, by evaluating other parameters like temperature and curing time of the mass element.

Concrete Maturity Is an Effective Solution!

According to ASTM C1074 [4], the strength of a given mix remains constant for the same maturity values, regardless of the curing conditions. Maturity serves as an index value correlated to concrete temperature over time. To determine the in-situ strength of on-site concrete at any given moment, the maturity index of the concrete on-site is calculated based on its temperature and correlated with established maturity-strength calibration.

Thanks to Internet of Things (IoT) devices, implementing the maturity concept has become easier in recent times. We can efficiently monitor the temperature and the strength of mass concrete remotely and simultaneously. This enables us to calculate temperature differences and assess temperature difference limits in real time. Now, contractors can shorten project timelines, reduce labor costs, and increase flexibility in structural design.

Conclusion

The performance-based temperature differential limit promises to be an effective solution to managing mass concrete construction. The implementation of IoT devices facilitates remote monitoring of concrete temperature and strength. This enables real-time calculation of temperature differences and performance-based limits. Thereby saving time, and costs and enhancing design flexibility for the feature creation of mass concrete structures.

References

- HM GOVERNMENT. Construction 2025: Industrial Strategy for Construction – Government and Industry in Partnership. Department for Business, Innovation & Skills, 2013, available at: https://tinyurl.com/2mk26pk9.

- AMERICAN CONCRETE INSTITUTE, ACI PRC 207.1-21. Mass Concrete – Guide. ACI, Farmington Hills, MI, USA, February 2022.

- AL-HASANI, L.E.M. Assessment of Mass Concrete Thermal Prediction and Failure Criteria: Novel Model, Evaluation Method, and Case Studies. Dissertation, Georgia Institute of Technology, 2022, available at: https://tinyurl.com/2xzpndpn.

- AMERICAN SOCIETY FOR TESTING AND MATERIALS, ASTM C1074-19e1. Standard Practice for Estimating Concrete Strength by the Maturity Method. ASTM International, West Conshohocken, PA, USA, 2019.