Rebar corrosion is a recurrent problem in the construction industry. More specifically, it can affect the quality of a project by cracking and damaging the concrete, as well as adding costs of repairs. However, there are new technologies that can help us deal with corrosion in a practical manner. In this blog, learn more about corrosion, how it affects concrete, and the importance of detecting the rate of corrosion in any project.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Corrosion of Steel in Concrete

Rebar corrosion is initiated when materials that are harmful to steel, such as CO2 and chloride from de-icing salt, start to penetrate concrete and reach the steel reinforcement. As an electrochemical reaction, electrons migrate from the anodic zone to the cathodic zone. This releases ferrous ions at the anode and hydroxide ions at the cathode. Eventually, this leads to a potential difference between the anodic and cathodic areas at the surface of the steel reinforcement. It can result in the creation of rust as a byproduct. Since rust occupies a larger volume than steel, it exerts internal pressure. As a result, it causes the surrounding concrete to crack and become damaged. These cracks make their way to the surface of the concrete. This causes even more CO2 and chloride to penetrate the concrete and speed up the process of corrosion.

The Cost of Concrete Corrosion

Reinforced concrete structures must be tested regularly to detect and prevent rebar corrosion. As these structures get older, the risk of corrosion in reinforcing steel continues to increase. This is important since a large number of structures were built using reinforced concrete between the 1950s and 1970s, especially bridges.

In North America, the average age of the continents’ 607,380 bridges currently in operation is 42 years old… With some of these structures as old as 80 years! On top of that, one in nine of these bridges is considered structurally deficient and nearing the end of its initial service life (Structure Magazine). Consequently, these structures require more frequent testing and repairs to eliminate damage and slow down the corrosion process.

Since concrete is the most widely used manufactured material globally, the industrialized world faces billions of dollars in concrete testing and repair costs. This is essential in order to keep structures sound and functional. In Switzerland alone, the annual cost of repairs can amount to between $6.6-$26.3 billion CAD. When taking this information into consideration, it is extremely important to accurately assess the condition of reinforced concrete structures in order to decide if repairs are required immediately.

Check out these different techniques when comparing corrosion on bridge structures!

Detecting the Rebar Corrosion Rate

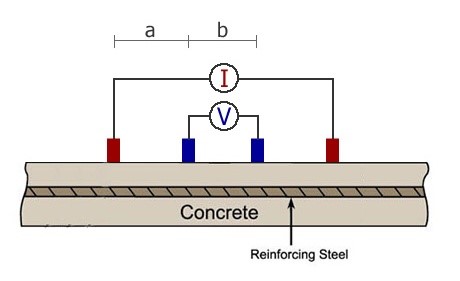

The electrical response of rebar embedded in the concrete can be determined from the surface of the concrete using the four-probe Wenner array configuration. As shown in the following figure, we can determine the response by applying a constant AC current between the outer probes and the measurement of voltage between the inner probes.

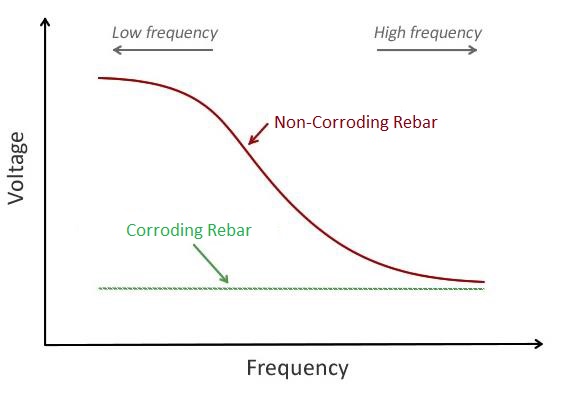

By sweeping the frequency of the AC current from low frequency to high frequency, the voltage response of the system changes. The variation of the voltage response of the corroding rebar is different from that of the non-corroding rebar. As shown below, the measured voltage when the rebar is not corroded increases in the low-frequency zone of the spectrum. However, it is almost invariable for the corroded rebar. This basic concept can be applied for the detection of the corroding areas of the reinforced concrete structures from the surface without the need to have an electrical connection to the rebar inside the concrete, unlike other existing non-destructive rebar corrosion measurement devices.

Although the low-frequency impedance response of reinforced concrete can be correlated to the corrosion state of rebar in concrete, its direct measurement is very time-consuming and vulnerable to noise interruption. Hence, it is not practical to use it to measure the corrosion rate of rebar inside the concrete.

A Practical Approach to Rebar Corrosion Detection

In the patented Connection-less Electrical Pulse Response Analysis (CEPRA) technology developed by Giatec, the low-frequency behaviour of the reinforced concrete system is determined by applying a narrow current pulse or a step voltage/current for a short period of time (in a couple of seconds) and simultaneously recording the voltage of the system with a high sampling rate. Using the recorded voltage and the applied current, the low-frequency impedance response of rebar in concrete can be extracted. This can be used to determine the state of corrosion in reinforced concrete structures.

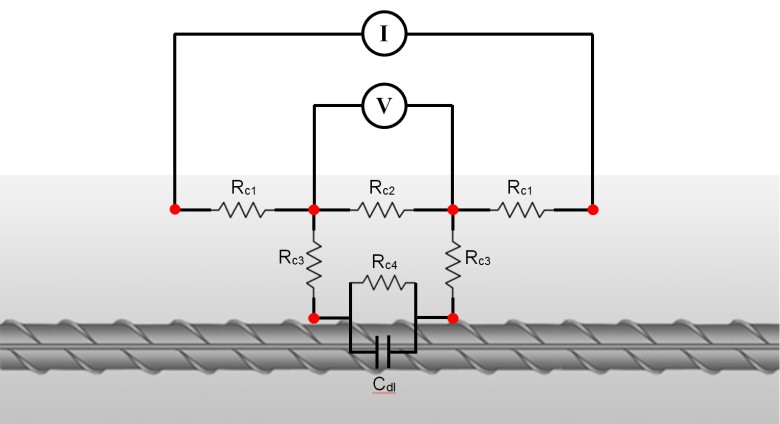

The CEPRA technology is implemented in a portable wireless device called Giatec iCOR®. This novel NDT tool employs a complex electrical circuit model for predicting different properties of concrete materials and steel reinforcement. This electrical circuit is schematically illustrated as shown below. An advanced mathematical algorithm is implemented in the core software of the device. This software processor is responsible for the analysis of certain characteristics of reinforced concrete structures such as the polarization resistance of embedded reinforcement and the ‘real’ electrical resistivity of concrete.

Knowing the polarization resistance, one can easily calculate the corrosion rate from the Stern-Geary equation.

CEPRA vs. Other NDT Devices for Rebar Corrosion Detection

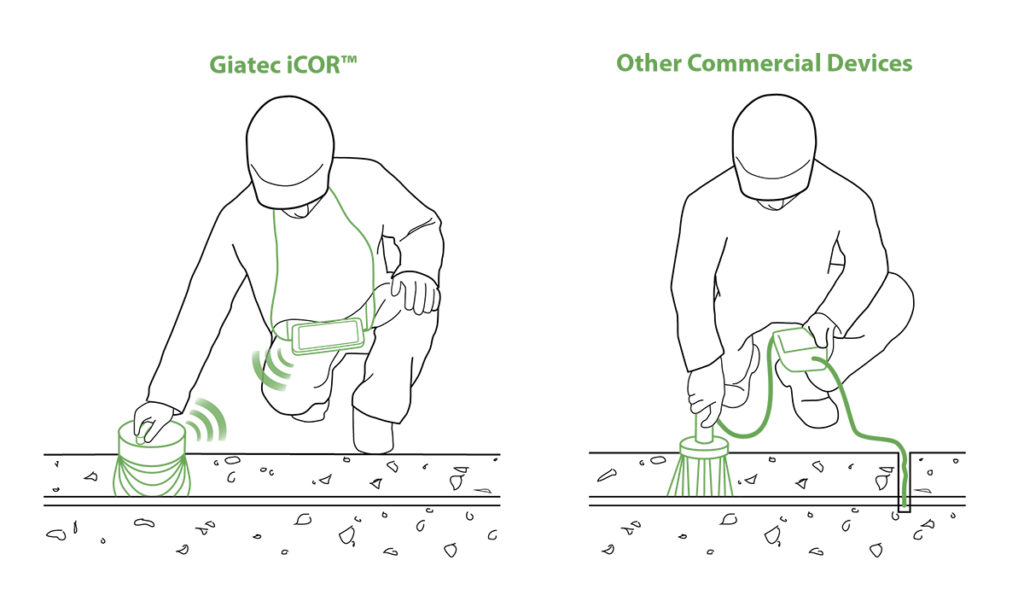

The CEPRA technology makes it possible to detect corrosion and measure the corrosion rate in concrete from the surface without the need to have a rebar connection. This is a great advantage as it allows us to perform onsite condition assessments quickly and efficiently. The CEPRA technology offers an accurate method of corrosion rate measurement. It confines the polarization area and does not get affected by the surrounding environment.

Unique Features of CEPRA:

- Directional measurement of corrosion rate, concrete electrical resistivity, and electrical resistance of the concrete cover

- Fast measurement within seconds

- No need to have an electrical connection to the reinforcement

Giatec iCOR

The sophisticated technique and the advanced algorithms behind the CEPRA technology are embedded in a hand-held device called iCOR. This device measures the electrical response of the reinforcement inside the concrete without a physical connection to the rebar. As a non-destructive testing tool, the iCOR is an award-winning device that has been recognized for its positive impact on corrosion monitoring and mitigation. Using our patented CEPRA technology, the device is unique in its ability to perform three-in-one concrete testing measurements of rebar corrosion rate, half-cell potential, and in-situ electrical resistivity. These measurements are critical to the success of rehabilitation projects and to the repair of concrete structures.

For this reason, the iCOR is the most convenient corrosion rate measurement device in the field. It also offers an innovative research tool for laboratory studies as well. It gives engineers a comprehensive understanding of concrete quality and the level of corrosion. Ultimately, it allows them to make faster, more informed decisions when it comes to rehabilitation and repair.

Using the communication tools in iCOR’s Android app, the data, reports and corrosion maps can be easily shared. Here is a quick walk-through video on the iCOR device setup and field testing:

Editor’s Note: This post was originally published in July 2016 and has been updated for accuracy and comprehensiveness.

2 Responses

What is the slab thickness that this technology can operate to? Multiple depths of rebar? Carbonization detection vs chloride detection? Can it discriminate various conditions?

Hello, thank you for your questions and interest. Regarding the slab thickness, the iCOR® device operates with a cover thickness from 1 to 9 cm (0.4 to 3.5 in) with an increment of 1 cm (0.4 in). The thickness of the concrete cover would affect the corrosion potential, as well as the electrical resistivity of concrete. A lower concrete cover leads to more negative values in half-cell potential measurements and lower values in concrete electrical resistivity of concrete. There is limited research on the effect of cover thickness on potential measurements; hence there is no straightforward correction procedure (SHRP, 2013). Therefore, it is recommended to verify the cover thickness for the area being tested in order to avoid misinterpretation of the collected data. Regarding the carbonization vs chloride detection and discrimination of various conditions, the iCOR® device uses a patented technology called Connectionless Electrical Pulse Response Analysis (CEPRA) and a reference electrode for half-cell corrosion measurement, which allows for measuring the corrosion rate and corrosion potential of steel reinforcement in concrete structures, being able to relate to concrete conditions based on RILEM TC-154 (2003).