As the demand for new concrete structures continues to increase, contractors need better and more efficient ways to test concrete quality and durability. For this purpose, several techniques have been developed and studied. One of those is Rapid Chloride Permeability Test (RCPT), which measures the concrete’s ability to resist chloride penetration and is standardized by ASTM C1202. Another is the electrical resistivity of concrete, which measures the concrete’s resistance to the flow of electrical current and is standardized by AASHTO T358, ASTM C1876, AASHTO TP 119 & CSA 23.3-26C. The RCPT tests have widely become accepted and are especially important for DOT’s when bridges and highways are undergoing construction. Additionally, they are useful for monitoring existing structures to determine and prevent deterioration of concrete and rebar corrosion due to chloride penetration.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Unfortunately, apart from being labour-intensive, the RCPT approach is also time-consuming. The test itself takes 6 hours to complete and requires extensive sample preparation. This includes cutting and conditioning the samples into a desiccator for 3 hours and then letting the specimens soak with water for another 18 hours prior to the test. When this is completed, there are even more steps to follow. What is more, this test method is often very expensive due to the amount of work required to perform the analysis.

Using Electrical Resistivity to Test Concrete Quality and Durability

A much faster and less expensive method for determining the quality and durability of concrete is electrical resistivity. Electrical resistivity has been used to measure the quality of concrete since the early 1910s, but in recent years state-of-the-art devices have been developed to improve this measurement process. This method assesses the ability of concrete to resist a chloride passage by measuring the concrete’s resistance to the flow of electrical current. As a result, it evaluates the quality control and service life prediction of concrete.

Electrical resistivity testing can be used to:

- Ensure concrete quality

- Measure chloride permeability

- Determine the Chloride Diffusion Coefficient

- Detect cracks

- Determine the setting time of fresh concrete

- Measure moisture content

Learn more about the science behind how electrical resistivity evaluates the quality of concrete.

Methods of Measuring Electrical Resistivity of Concrete

Here are some different techniques for measuring the electrical resistivity of concrete including bulk resistivity, surface resistivity, and embedded electrodes for fresh concrete.

Bulk Resistivity: ASTM C1876, AASHTO TP 119 & CSA 23.3-26C. Two electrodes are used to send and read the current flow in a hardened concrete sample using two parallel electrode plates which transmit an alternate current (AC).

Embedded Electrodes in Fresh Concrete: Embedded electrodes are used to track changes in the concrete hydration process, enabling the user to measure water content, predict the concrete setting time, and detect cracking.

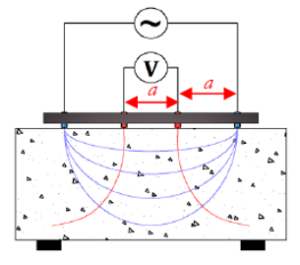

Surface Resistivity: AASHTO T358. Uses the Wenner-Array setup in which four electrodes are positioned in a straight line and equally spaced. The two outer electrodes send the current into the concrete, while the two inner electrodes measure the concrete’s electrical potential.

Copyright of Giatec Scientific Inc.

The Time-Savings Potential of Surface Resistivity

All these methods of testing concrete quality and durability are valid. However, the potential of surface resistivity to monitor concrete yields huge advantages. This is especially true when compared to current chloride permeability tests.

The RCPT method takes 6 hours for test results to be returned and extra time to prep concrete samples for testing. However, with surface electrical resistivity testing and AASHTO T358: Surface Resistivity Indication of Concrete’s Ability to Resist Chloride Ion Penetration, you can evaluate the quality and permeability of your concrete in seconds. This saves significant time in both labour costs and quality control testing costs for DOTs and testing agencies. States such as Florida and Louisiana have already realized the significant cost savings associated with this testing method and have incorporated it into their specifications.

An Overview of AASHTO T358

- 1. Prepare a minimum of three samples (cores or 4’ x 8’, 6’ x 12’ cylinders)

- 2. Set up a 4-pin Wenner probe array:

- 2.1 AC current is applied on the outer pins

- 2.2 Potential difference between inner pins is measured

- 3. Two sets of four readings (0°, 90°, 180° and 270°)

- 4. Current applied, resultant potential and sample area are used to calculate the surface resistivity of the concrete, which can be correlated with the resistance to chloride ion penetration.

Giatec’s Surf™ device is the fastest and most accurate technology for the measurement of surface resistivity, which demonstrates the state of quality of concrete.

Surf™ can be used to evaluate:

- Performance-based quality control of concrete

- Estimation of the chloride diffusion coefficient of concrete

- Service life design of concrete structures

- Estimation of the remaining life of concrete structures

- Crack detection in concrete elements under load

- Monitor the setting time of fresh concrete

Surf™ has a unique and customized setup, which enables the measurement of electrical resistivity with high accuracy by reducing the duration of the test, minimizing the ambient effects and reducing human error. The patented technology automatically measures resistivity 8 times around the concrete specimen using four channels of a 4-probe array which are located at 90° from each other. These measurements are used to determine electrical surface resistivity, AASHTO T358, which can be correlated to ASTM C1202, the resistance of chlorine penetration in the concrete.

| Chloride Ion Penetrability | AASHTO T358: Surface Resistivity (kohm-cm)

a = 1.5 in. |

ASTM C1202 – Rapid Chloride Penetrability (Coulombs) | |

| 4-by-8 in. (100-by-200-mm) | 6-by-12 in. (150-by-300-mm) | ||

| High | <12 | <9.5 | > 4000 |

| Moderate | 12-21 | 9.5-16.5 | 2000-4000 |

| Low | 21-37 | 16.5-29 | 1000-2000 |

| Very Low | 37-254 | 29-199 | 100-1000 |

| Negligible | >254 | >199 | <100 |

a = Wenner probe tip spacing

This shows the qualitative relationship between the rapid chloride penetrability test (RCPT), and the surface electrical resistivity of concrete. This device can also be used for durability-based quality control of concrete and for monitoring the service life design of a structure.

Electrical resistivity testing is an important step in the process of assessing durability factors of concrete, such as permeability, diffusivity, and other micro-structure characteristics which can be correlated to other properties, such as; chloride diffusion coefficient, water absorption, and the rate of corrosion of rebar in reinforced structures. Electrical surface resistivity testing, AASHTO T358, is often required to assess quality assurance in new builds

These characteristics provide, not only a quantitative assessment of the concrete quality but also general guidance on the current durability status of any given concrete element. This technology has the potential to save significant costs associated with testing and labour for DOTs, testing agencies, and contractors.

Based on the AASHTO T358 standardized method, Giatec’s Surf™ device is the fastest and most accurate technology for the measurement of surface resistivity, which demonstrates the state of quality of concrete.

2 Responses

Hi Vijay,

From your electrical resistivity values you can refer to the following paper as a guide to build a correlation between diffusion coefficient and conductivity (the inverse value of resisitivity):

https://www.giatecscientific.com/wp-content/uploads/2015/05/Concrete_Electrical_Resistivity.pdf

Please note that we only suggest this paper as a general guide, given the limitations from the experiment (i.e. 20 concrete mixtures were tested). Diffusion coefficient and conductivity are subject to variations depending on your concrete mixture, cement type, etc. You can relate to the linear relationship from the Nernst-Einstein equation (concrete in SSD condition) to build the diffusion coefficient relationship. Furthermore, to estimate service life of concrete, there are some available software that could help you with that, such as Life365.

Please feel free to email us at support@giatec.ca if you need further details.

We have iCOR from which we can evaluate surface resistivity.

Can you please guide us on how to find the chloride diffusion coefficient from electrical resistivity and the service life of concrete?

Thanks

Vijay Kulkarni India