The awareness of concrete durability properties has increased notably in recent times. The advancement of concrete technology has allowed the optimization of concrete testing procedures. Nowadays, more infrastructure projects show signs of deterioration due to the ingress of deleterious substances such as chloride, which causes the corrosion of concrete. Consequently, regulatory bodies and standardized testing agencies are observing new technologies in concrete testing. In this blog, we learn the similarities in results and the differences in procedures between Concrete Electrical Resistivity (ASTM C1876) and the Concrete RCPT method (ASTM C1202). Likewise, we will discuss the advantages of concrete resistivity equipment as opposed to other devices.

Detect the Rate of Rebar Corrosion in Seconds

Rapid Chloride Permeability of Concrete Test

The Rapid Chloride Permeability Test (RCPT) indicates the concrete’s ability to resist chloride penetration. This is an important factor of concrete’s durability as discussed previously in our blog Chloride Diffusion and Concrete Corrosion. However, the RCP test procedure is time-consuming. While it evaluates concrete mixtures, it usually takes 6 hours to perform. Conditioning the samples into a desiccator could take another 3 Hours. Additionally, the samples need to be soaked with water for 18 hours. Performing this test regularly would be impractical in the fast environment of the construction industry. This is because concrete ready-mix plants produce several distinct mixes every day. However, we cannot overlook the results of RCPTs as they bring valuable insight into the durability status of concrete mixtures.

For this reason, a test that can produce similar insight into concrete mixtures with a simpler procedure is paramount to facilitate and promote the usage of concrete durability parameters in new projects and help expedite inspection & repair for existing projects.

Electrical Resistivity of Concrete

Electrical Resistivity is a non-destructive testing method that can evaluate the microstructure of concrete. It can be related to the volume fraction of pores and pore solution conductivity. Furthermore, it predicts the diffusion coefficients of chloride ions and water permeability. The RCP test we explained before typically determines the chloride resistance of concrete. However, electrical resistivity also helps to assess the ability of concrete to resist chloride penetration.

There are two main testing methods to evaluate concrete’s electrical resistivity

- Bulk Electrical Resistivity following the ASTM C1876, CSA A23.3-26C, and AASHTO TP 119 standards, test set-up is shown in Graph (A).

- Surface Electrical Resistivity following the AASHTO T358 standard, test set-up shown in Graph (B).

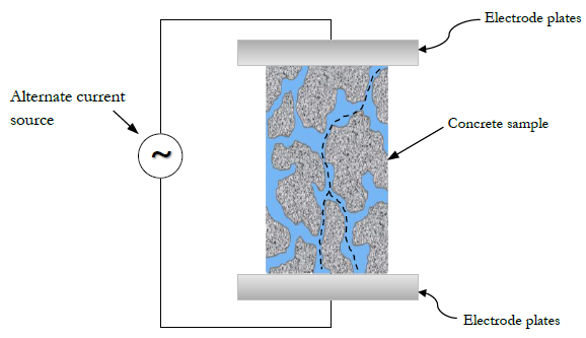

In the Bulk Electrical Resistivity test, a hardened concrete sample is placed between two electrode plates that apply an alternate current (AC) with different frequencies. A device measures the potential drop in voltage between the two electrode plates in a matter of seconds. This equipment would not need sample cutting, soaking in water for 18 hours, conditioning for 3 Hours, or waiting 6 Hours for the test to conclude. The Bulk Resistivity test allows the usage of regular cylindrical or cubic samples.

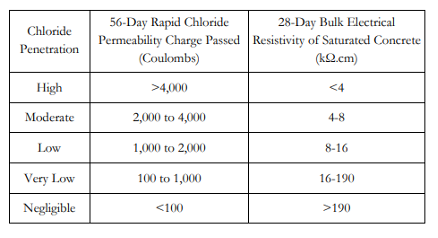

The RCP test is typically expressed in charges passed (Coulombs) and measures Chloride Ion penetration of concrete following ASTM C1202. The Bulk resistivity and the charges passed correlate. Given the time-consuming procedure of RCP test, and the simple Bulk Resistivity test where almost no sample preparation is necessary, it is inevitable that the Bulk Resistivity test will facilitate the use of durability parameters in quality control procedures in concrete mixes and simplify structural inspection on existing concrete structures1.

Likewise, another advantage of the Bulk Resistivity test is that the sample used for testing could also be used for compressive strength testing. The table below shows the correlation between the Charges passed (Coulombs) from the RCP test and the Bulk Electrical Resistivity:

The Best Concrete Resistivity Equipment

The RCON™ device by Giatec provides an easy way to perform Bulk Electrical resistivity as an alternative to traditional RCP testing. For more clarity between the two testing methodologies discussed in this blog, the table below highlights the main differences:

| Comparison point | Bulk Resistivity (ASTM C1876) | RCPT (ASTM C1202) |

| Sample Preparation | Not Required | Cutting samples into Thirds Grinding and Levelling |

| Sample Conditioning | Not Required | 3 Hours inside desiccator |

| Soaking samples in water | Not Required | 18 Hours of Soaking |

| Testing Time | The test is completed in Seconds | 6 Hours |

| Destructive to sample? | Non-Destructive. The sample could be used for Compressive Strength | Partially destructive: requires sample cutting to fit the test cell |

| Results/ Outcome | Chloride Ions penetration resistance of concrete | Chloride Ions penetration resistance of concrete |

It is clear from the table above the value the RCON concrete resistivity equipment testing brings to concrete professionals in quality control, time-saving, and ease of testing.

In brief, the Bulk Electrical Resistivity test through the RCON device is a unique tool to investigate the following:

- Performance-Based Quality Control of Concrete.

- Diffusion of Chloride in concrete.

- Corrosion of Rebar in Concrete.

- Setting Time of Fresh Concrete.

- Moisture Transfer in Concrete.

- Micro-Crack Development in Concrete.

Likewise, the RCON device is also capable of performing Electrical Resistivity testing on fresh concrete samples. This is possible because the instrument uses “Embedded Electrodes” which track changes in the concrete’s hydration process. During that process, the hardening of concrete causes the reduction of moisture. Here, the electrical resistivity of concrete will increase with the hydration process.

In essence, the advancement of durability, and quality control testing procedures allows concrete professionals to raise the standard, and performance of new concrete structures. Electrical Resistivity is one of the recent advances in concrete that allows for the broader use of durability parameters. This works great in new projects for the ease of testing procedure, sample preparation, and conditioning. Moreover, the value obtained from the results can encourage construction professionals to optimize their mixtures and avoid future detrimental effects of neglecting the durability of concrete tests due to time and resource-consuming efforts.

1 Use of Bulk Electrical Resistivity on pre-existing structures is through testing core samples extracted from the structure in the analysis.