Despite the complexities and unexpected challenges that cold weather brings to the concrete pouring process, the industry has made great advances when it comes to tools and solutions. Today, it is possible to record temperature and strength data wherever you are and at any time. Let’s delve into the game-changer features that Giatec’s products, SmartRock® and SmartHub™, bring to the job site for the coldest months if the year.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

SmartRock® Sensors and Cold Weather Concrete

SmartRock is a wireless concrete sensor designed for temperature and strength monitoring with the ability to record real-time temperature data for every 15-minute interval for 2 months and comes with remote-monitoring capabilities. It is fast, simple, designed rugged , and waterproof, and can be activated and installed hassle-free. The sensor contains two points of temperature measurements located in the sensor cable and body and comes with an extended temperature cable and probe for mass concrete purposes. This sensor can measure temperature as low as -22℉ (-30℃) with an accuracy range of ±1℃.

The SmartRock sensor, containing a black box, a cable, and an installation strap, can be fully embedded below the concrete surface. Temperature data is collected at two locations in the sensors’ cable and body, of which the cable can be secured to the rebar, making it require zero maintenance. The strength of the in-place concrete is calculated automatically based on the maturity method in accordance with (ASTM C1074). These results are accessible remotely and in real-time through the SmartRock mobile app and on the Giatec 360™ cloud dashboard to help you make informed decisions. Smart Rock’s AI assistant, Roxi™, eliminates human error by sending smart notifications and alerts to give you the utmost confidence in your mix calibration data and the accuracy of strength test results. On top of all this, we even made it easier for you to generate as many reports as you need, in both PDF and CSV formats, using our dashboard 360 and the SmartRock mobile app.

Some of the applications of our sensor include

- Temperature-differential analysis

- Accelerated formwork removal

- Quality control

- Speed up post-tensioning

- Open roads to traffic faster

- Optimize curing conditions

- Improve saw-cutting time

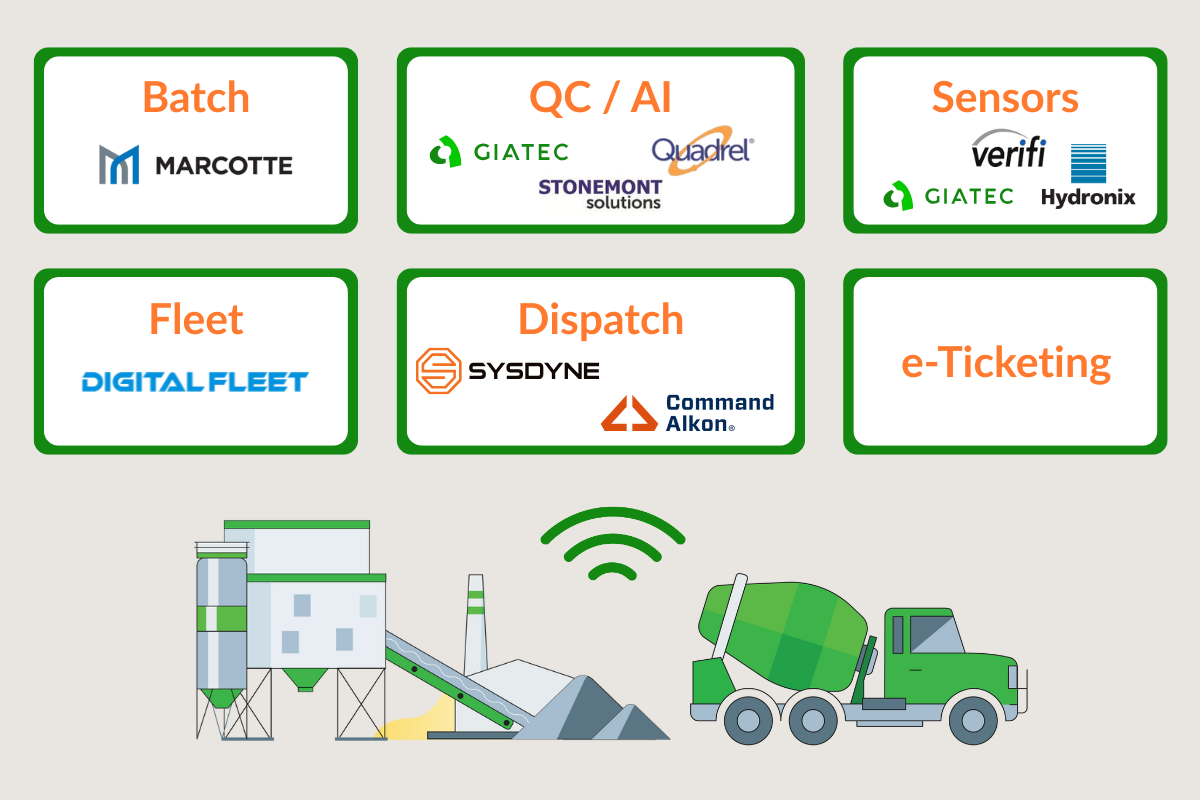

With the use of these sensors, the manpower on site now does not have to wait hours anymore to record the temperature and strength or have to perform the laborious work of transporting the samples to a lab for testing. As a step up, these SmartRock sensors can also be utilized with a SmartHub to remote monitor the readings 24/7 and have the capability to connect with an ‘n’ number of sensors and display results on your phone or computer in one touch.

SmartHub and its Relationship With SmartRock Sensors

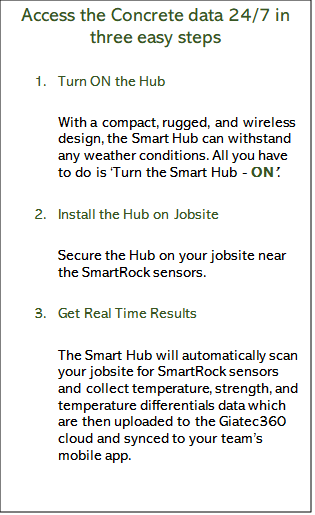

SmartHub is a remote monitoring system for accessing SmartRock sensor’s concrete data anytime, anywhere. The Hub automatically collects the data recorded by the SmartRock sensors and uploads it to the Giatec 360 cloud dashboard via LTE where it is synced to your team’s mobile devices in the SmartRock app. The Hubs alert system sends smart notifications to let you know when your concrete reaches specific temperature or strength thresholds. With real-time information, you always know when your project is ready to move to the next steps in the construction process, allowing you to optimize your schedule.

SmartHub Applications

With the remote monitoring system – SmartHub, it is now possible to access critical data 24/7, perform quality control, optimize the curing conditions, effectively utilize it in hazardous locations where it is hard to reach, and, most importantly, use it in hot and cold weather conditions. The SmartHub’s wire-free and wireless technology ensures you always have full and timely control of your project.

For example, let’s consider a real-time scenario in winter, the workers on the job site must perform a series of critical activities in order to monitor the concrete temperature and strength; these processes are extreme and exhausting during harsh, cold-weather conditions. Nevertheless, with the use of Giatec’s SmartHub, you can flawlessly connect to the SmartRock sensors that are installed on the site, providing 24/7 remote monitoring and real-time alerts. Armed with this information, you will always know when to move to the next steps in the construction process, allowing you to easily optimize your schedule, and minimize the need for on-site, manual monitoring of the concrete data; thus, serving as a champion in cold weather concreting practices.

Making Cold Weather Concrete Faster, Safer, and Efficient

Yes, you read that right. Today is possible to record temperature and strength with remote monitoring capabilities, even 24/7 with the use of Giatec’s SmartRock sensor and SmartHub. During cold weather, it is very tough for the workers to stay on-site to record temperature and gather concrete strength data. However, with the use of SmartRock sensors and SmartHub, all these hurdles can be neglected, and a worker can monitor data without even having to visit the site. The data is sent directly to your mobile device in real time. A user can set up threshold limits on the app for both temperature and strength, once these limits have been reached, they can receive notifications alerting them about the target being achieved. This will greatly help the users keep up with the schedule or even optimize them, accordingly, identify any problems and resolve them at the earliest, avoiding delays and saving a considerable amount of time which directly results in cost-savings for the project.

Therefore, with Giatec’s revolutionizing technology, it is now possible to make cold-weather concreting faster, safer, and more efficient. The winter season can be the most wonderful time of the year, even in the construction industry.