With the evolution of the construction industry, we are building structures bigger than ever before. These massive structures are mostly made of concrete and often represent a challenge for many reasons. One of the main problems encountered is the concrete temperature difference between the core and the surface of massive pours and the cracking or structural deficiencies that could result from this differential.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

The Daniel-Johnson Dam in Quebec, Canada.

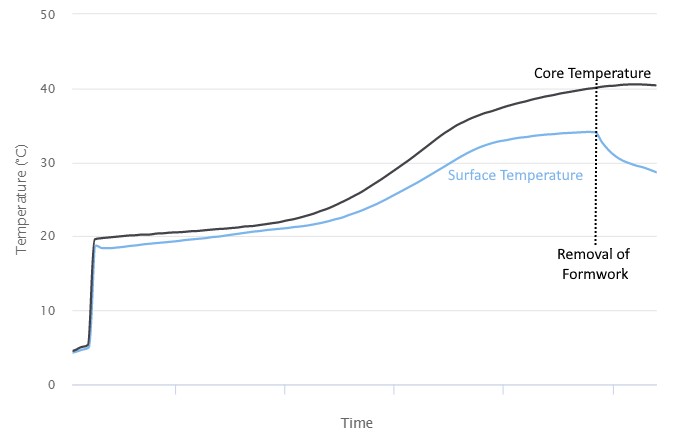

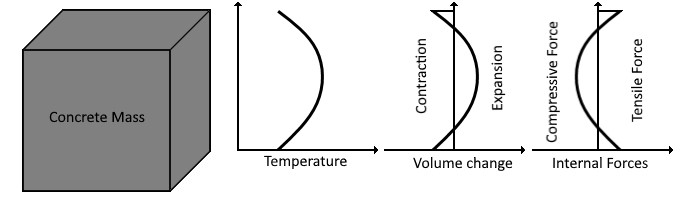

The concrete temperature gradient (or temperature differential) is the variation of the temperature found between the core and the exterior of a concrete element. A concrete pour will typically generate an appreciable amount of heat, due to the exothermic nature of concrete hydration, which will raise the temperature of the element. The problem lies in the fact that the exterior of the concrete is exposed to the environment, with a lower temperature. This results in the outside of the element being cooled down, while the center remains at a high temperature.

Want to know more on temperature monitoring in concrete?

Then, the concrete being at a high temperature, will expand in volume, whereas the surface will be cooled down and will then contract (alternatively, the surface will expand but at a lower rate than the core.) This is a problem, as the element will have very different changes in volume throughout its depth. Overall, what will happen is that internal stress will be created in the mass and, if this stress exceeds the tensile strength of concrete (the resistance of a material under tension), cracking will occur. Obviously, cracks in a concrete element are something to avoid, as they will greatly reduce the service life of the structure.

Here’s more information on thermal cracking in concrete

How to Prevent Thermal Cracks

The construction industry has solutions in order to reduce this difference in the temperature, helping to maintain the volume changes at a minimum. The measures can be applied before or after the pour. The first solution is to reduce the amount of cement used in the mix design, which will reduce the heat generation during the hydration of the cement. Alternatively, high volumes of supplementary cementitious materials (SCM), such as fly ash and slag, can be used to reduce this rise in heat. However, this is not always an appropriate response when specific durability requirements are necessary for the element, limiting the minimum cement content or maximum SCM replacement levels. It is also possible to use cooled water or even ice in the mix, or to cool down components (like aggregates) before mixing. Then, once the pour is done, the cure of the element (lamps, heaters, etc.) will hopefully prevent the surface from cooling down too fast. For some massive elements, it can even be necessary to have a pipe system running water through the core of the concrete element. Those measures, amongst others, will prevent the concrete temperature gradient from being too high to accommodate.

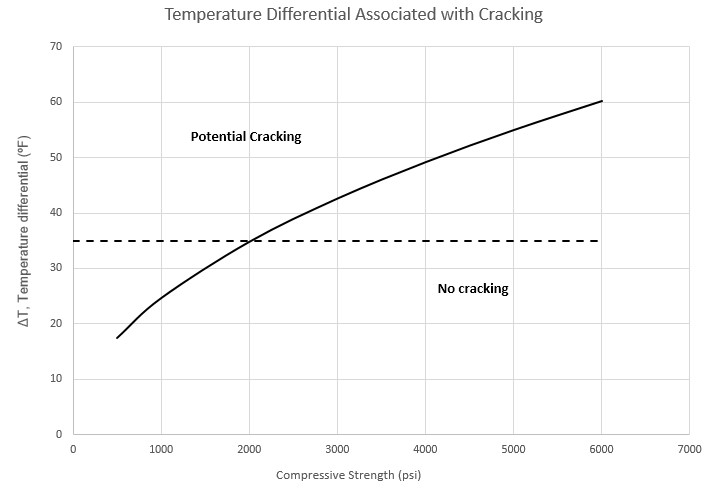

The ACI 207- Mass Concrete guideline states that the difference in temperature between the center of the element and the surface must remain smaller than 35 ºF (20ºC) during curing. In the majority of cases this approach is very conservative, in other cases it can be an overestimation of the allowable gradient.

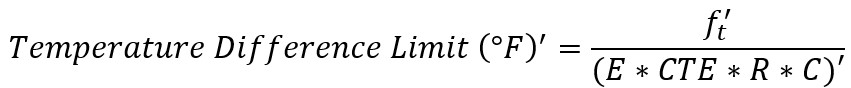

It is well established that as concrete hardens, the tensile strength increases, which means that the concrete is able to withstand higher stress due to the temperature gradient differential as it cures. The following temperature difference limit equation can be used to determine that maximal difference:

F’t, which represents the tensile strength, can be monitored at the surface of the mass element by using the maturity method. This requires a maturity calibration to be done before the pour. “E” represents the modulus of elasticity and “C” the creep factor, which can be taken as 1 to be conservative. The coefficient of thermal expansion (CTE) can be obtained by performing the AASHTO T336 test. Additional information on how to obtain these factors are provided in ACI 207.2R. This method can allow for the temperature difference limit to increase as the concrete hardens and gains strength, provided that the in-situ tensile strength is accurately determined over time.

In the past, obtaining the actual in-place strength was a challenge, but with recent developments in technology, using concrete maturity testing to determine the in-place strength has become a lot easier. With SmartRock®, it is possible to know the temperature of the core and the surface at the same time, as well as getting the strength in both locations. By using the maturity principle and mix calibrations, the temperature gradient in a concrete structure and the actual in-place strength of the element can be known, at any time, as well as what the allowable temperature gradient is for the concrete. Just install the sensors on the rebar before the pour, install a SmartHub™ on site and data will automatically be sent to the mobile application. With those values available, it is known exactly when the concrete is in danger of thermal cracking. With the “Gradient Analysis” in the Giatec 360™ dashboard, thresholds can be programmed, and notifications can be set up so you are alerted when the differential temperature limit is crossed. Appropriate corrective measures can then be adopted to ensure a concrete with minimal cracking.

Click here for more information on Giatec 360

With this method, the concrete temperature differential is increased to a maximum without the hassle of outdated wired thermocouples. It is a safe method for all kinds of projects, but especially useful for massive pours that are a danger to the service life of a structure.

2 Responses

Thanks for the detailed explanation on how to prevent thermal cracks arising out of temperature by less use of cement and/or use of SCM. My concern is that for a particular product mix, we have to use certain quantity of cement. But by replacing the OPC with blended cement ( PPC or PSC) in the same quantity will the temperature be control thereby reducing cracks in the concrete?

Hello, thank you for your question and interest. Different mixes based on PPC or PSC will definitely have different properties than the OPC-based mix, however, it is not possible to conclude in a direct manner that by replacing one by the other in the same quantity the temperature will be more controlled and reduce the cracks in concrete, as there are other variables involved.