Concrete maturity is an index value that represents the progression of concrete curing. It is based on an equation that takes into account concrete temperature, time, and strength gain. Concrete maturity measurement is an accurate way to determine real-time strength values of curing concrete.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

A Fast Approach for Estimating In-Situ Compressive Strength

Early, rapid, and accurate in-situ estimation of the compressive strength of concrete is one of the major challenges for the concrete industry. A practical solution for such challenges can prevent multi-million dollars of extra annual investment for the construction industry and owners of civil structures since the annual global production of concrete is estimated at 3.8 billion cubic meters. An accurate and reasonable in-situ estimation of the compressive strength provides the opportunity to optimize the concrete mix design as well as the formwork removal time. The optimization of mix design affects the consumption of raw materials (e.g. cement and aggregates) and alternative materials (e.g. natural pozzolans and supplementary cementitious materials like fly ash and silica-fume). Considering the high volume of global consumption of concrete, this could, in turn, effectively optimize the consumption of resources and reduce a great extent of CO2 and toxic materials (emitted during cement production) into the atmosphere.

The maturity method is a convenient approach to predict the early age strength gain of concrete, using the principle that the concrete strength is directly related to the hydration temperature history of cementitious paste. The maturity concept for estimating the strength gain of concrete is described in ASTM C1074, Standard Practice for Estimating Concrete Strength by the Maturity Method. This method can potentially address many immediate challenges facing the concrete industry such as predicting the appropriate time for formwork stripping and post-tensioning, especially at low temperatures while the strength development of concrete is hindered; and optimizing concrete mix formula and concrete curing conditions (e.g. concrete heating at low temperatures or surface protection in hot-dry weathers). Lack of an accurate estimation of strength at early ages of construction is twofold: contractors either wait too long for the next action (e.g. stripping formwork) which is costly due to delays in completing the project, or they act prematurely which could cause the concrete structure to crack – that would lead to future durability and performance issues – or even structural collapse.

Learn all about the maturity method, including its theory and applications! Review it here!

In most construction sites, field-cured concrete samples are tested for strength at various ages during the first week since concrete is poured, in order to make a decision on formwork removal. ASTM C873 offers a test method for cast-in-place cylindrical specimens. These specimens can be removed later to measure the compressive strength of concrete in the lab. Usually, if the concrete reaches 75% of its designed strength, the structural engineers allow for the striping of forms. The problem, however, is that only one specimen is crushed for strength estimation. This is not necessarily accurate. This method is limited to use in horizontal and thick concrete elements like slabs. In addition, the construction crew is usually on the job site while they are waiting to hear about the compressive strength results from the lab. This adds to the cost of construction and its uncertainty decreases the efficiency of the construction.

Although alternative methods such as concrete maturity measurement exist, there is resistance to utilizing them for most concrete projects. Except for specific projects, the concrete industry shows interest in the commonly used compressive strength test. This is mainly due to the upfront cost of concrete mixture calibration for maturity curves, and the lack of expertise in the installation of concrete temperature sensors, data collection, and analysis.

Such approaches to compressive strength evaluation may cause concrete contractors to make conservative decisions, face more complicated technical problems (e.g. delay in formwork stripping, and unnecessary long-term curing and surface protection), and spend more financial resources.

As non-destructive testing, the concrete maturity measurement method may be a reasonable candidate to fill this gap. In comparison to most on-site non-destructive technologies (e.g. Schmidt Hammer or Ultrasonic Pulse Velocity), the privilege that the maturity method stands on is that the procedure for estimating the compressive strength would be objective and qualitative once the maturity curve is developed and adopted.

This technical article describes how the maturity curve is developed, and how it is applied for on-site estimation of the compressive strength of concrete.

Interested in learning about how we use concrete maturity measurement for our SmartRock wireless sensors? Read all about it HERE!

What Is the Principle of the Concrete Maturity Method?

The maturity method is a relatively simple approach for estimating the in-place compressive strength of concrete, specifically at early ages less than 14 days. Once the maturity curve is developed in the laboratory for a specific project, it can be used for on-site estimation of the compressive strength of concrete in real time.

The maturity value is governed by the fundamental assumption that a given concrete mix design poured during the course of a specific project has the same compressive strength when it has the same “maturity index”. It means that a given concrete mix formula or mix, for example, may reach the same compressive strength after 7 days of curing at 10 °C when it is cured at 25 °C for 3 days.

The concrete maturity measurement method based on the ASTM C1074 is the most commonly used to estimate the in-situ strength of concrete. ASTM C1074 provides two maturity functions: 1) Nurse-Saul function; and 2) Arrhenius function. Based on the Nurse-Saul method, there is a linear relationship between the maturity and the temperature in real-time. The underlying assumption is that the strength development in concrete is a linear function of hydration temperature. Equation 1 shows the relationship between maturity and hydration temperature history.

Where: M(t) is the maturity index at age t; Ta is the average temperature during time interval ?t; T0 is the datum temperature. ASTM C1074 provides a standard procedure to find the datum temperature for a specific mix design. However, most of the previous studies suggest a practical estimation of the datum temperature that is between 0 °C and -10 °C. Indeed, this is the temperature at which the hydration of cementitious paste stops; hence the strength development of concrete ceases. Unpublished results by Giatec Scientific Inc. show that this temperature resides within an interval between 0 °C and -5 °C dependent on the concrete mix formula.

The second approach is the Arrhenius function which assumes there is an exponential relationship between the compressive strength and hydration temperature. The maturity index is defined in the form of an equivalent age at a reference temperature. It means the actual age should be normalized to the reference temperature in order to estimate the compressive strength. This function needs a value of activation energy that can be determined as the procedure detailed in ASTM C1074.

Despite the fact that the Arrhenius function is scientifically more accurate, the Nurse-Saul function is more commonly used by the concrete industry for the following reasons:

- The accuracy of the Nurse-Saul function is adequate for most field applications;

- The Nurse-Saul function is relatively simpler compared with the Arrhenius function.

How is the Maturity–Strength Curve Adopted Via the Nurse-Saul Function?

As detailed in ASTM C1074, there is a step-by-step guide for developing the maturity curve, and for estimating the compressive strength. These steps are described as follows.

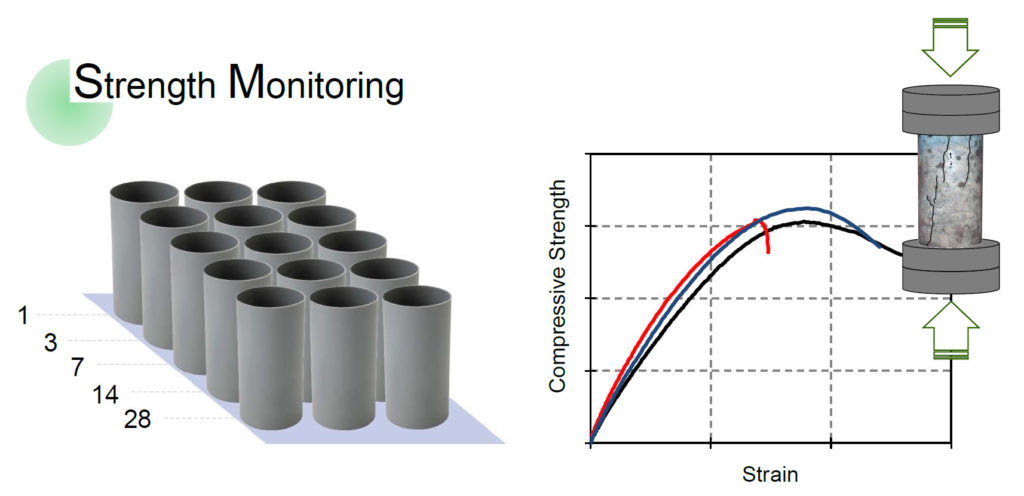

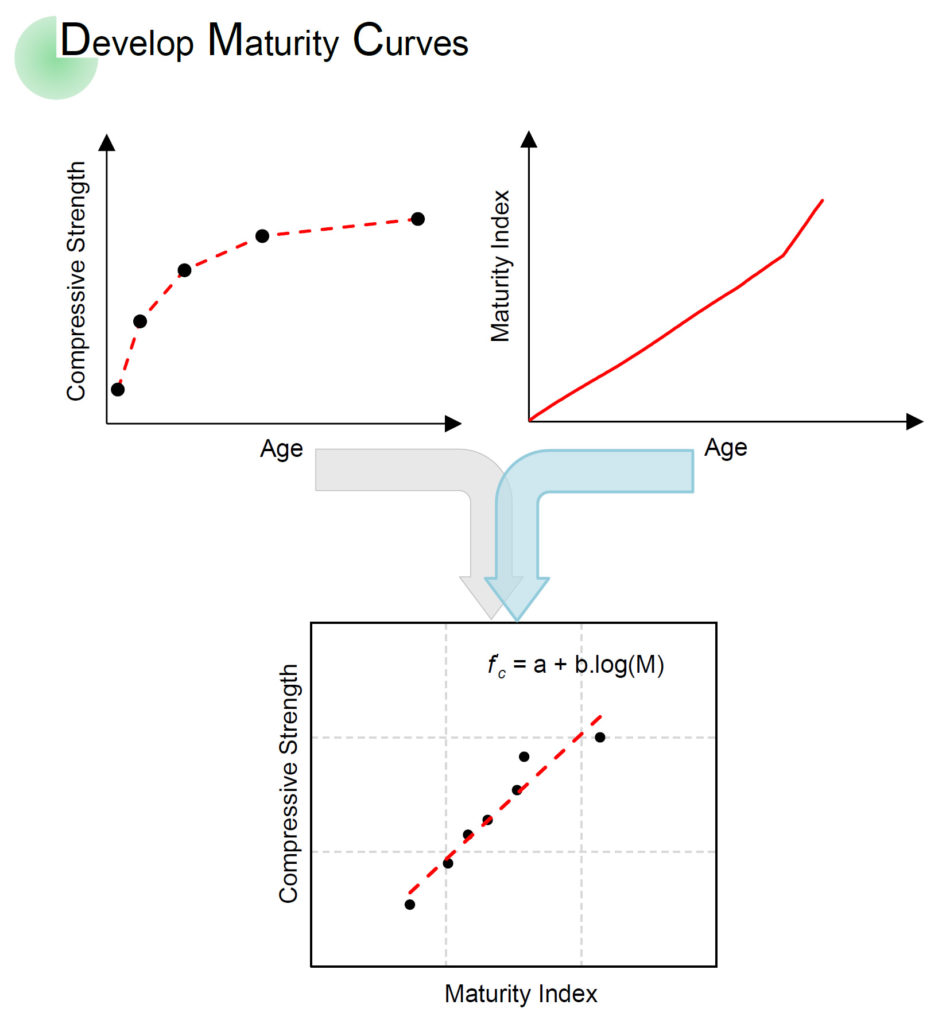

The maturity-strength curve represents the relationship between maturity index and compressive strength for a specific concrete mix design, adopted in the laboratory. To do so, adequate concrete cylindrical specimens should be cast, and then stored in the semi-adiabatic condition for curing. A certain number of concrete cylinders (i.e. at least two concrete specimens) should be equipped with embedded temperature sensors for recording the hydration temperature history. The compressive strength of concrete is measured at ages of 1, 3, 7, 14 and 28 days.

The maturity index is calculated at strength testing times using Equation 1. Then the best curve will be fitted for the strength data versus maturity index data. It should be noted that it is important to test the concrete mix design that will be the same as that used in the construction project. Any deviations from the original mix design (such as water-to-cement ratio, cement content, etc.) will reduce the accuracy of the maturity method to estimate the compressive strength.

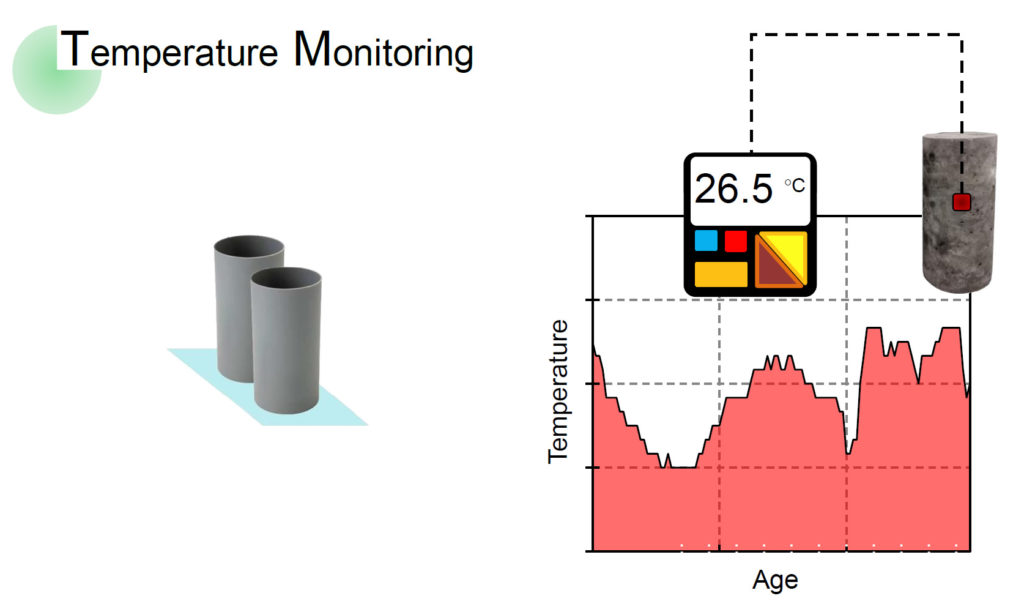

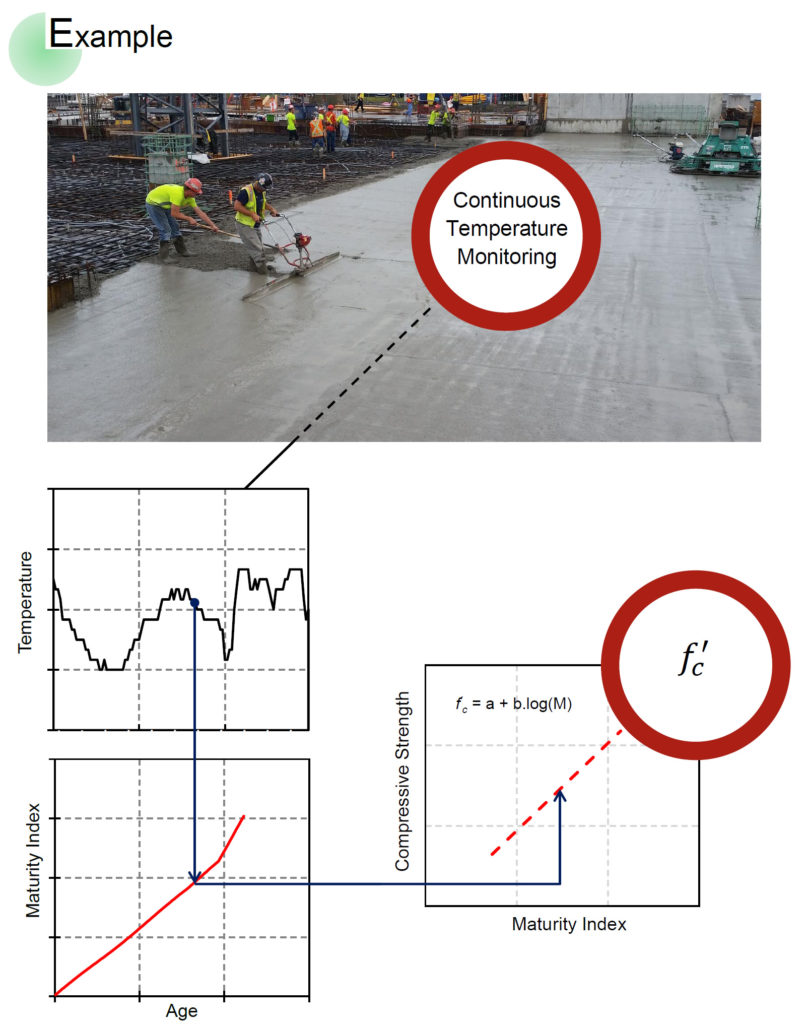

Once the maturity–strength curve is developed, it can be used to estimate the in-place concrete strength using the hydration temperature history. To do so, the temperature history of the concrete elements should be recorded after pouring using embedded sensors at the locations that are generally critical in terms of exposure conditions, curing and structural requirement. Routine quality control tests should be performed to ensure the accuracy of the maturity–strength curve. These controls minimize any error in the estimation of in-place strength due to inherent limitations of the concrete maturity measurement method.

Some of the important limitations of this method are listed as follows:

- In-place concrete is not representative of the concrete used to develop the calibration in the lab. This can be because of changes in materials, water-to-cement ratio, air content, batching method, etc.

- In-place concrete is not properly placed, consolidated, cured, etc.

- Very high early-age temperatures can lead to inaccurate estimation of strength at later ages;

- Using a datum temperature (for the Nurse-Saul function) that is not representative of the concrete mixture can result in an incorrect estimation of strength.

Several maturity meter devices have been developed that can measure the hydration temperature of concrete in real time. Most of these devices such as Flir Intellirock, Command Center, and Concure iDrop can calculate the maturity index and predict the compressive strength of the maturity–strength curve, datum temperature, and any required information is developed. Most of these devices include a temperature sensor embedded into the concrete elements plugged into the data logger via an electrical cable. Alternatively, a simple thermocouple could be embedded in concrete for temperature monitoring using a connected data logger. The data should then be extracted and used to calculate the maturing index and used to estimate the concrete strength from the maturity curve.

Standards for Concrete Maturity Measurement

The maturity method is widely standardized and accepted by building codes. This section summarizes different codes and standards accepted by different countries or regions. Countries that do not define maturity in their code typically follow ASTM standards. There are also multiple countries that are actively working on standardizing or approving the method for their own standard practice.

United States

ASTM C1074: Standard Practice for Estimating Concrete Strength by Maturity Method

ASTM C918: Standard Test Method for Measuring Early-Age Compressive Strength and Projecting Later-Age Strength

ACI 318- 6.2: Building Code Requirement for Structural Concrete and Commentary

ACI 228.1R: In-place Methods to Estimate Concrete Strength

ACI 306R: Guide to Cold Weather Concreting

AASHTO T325: Standard Method of Test for Estimating the Strength of Concrete in Transportation Construction by Maturity Tests.

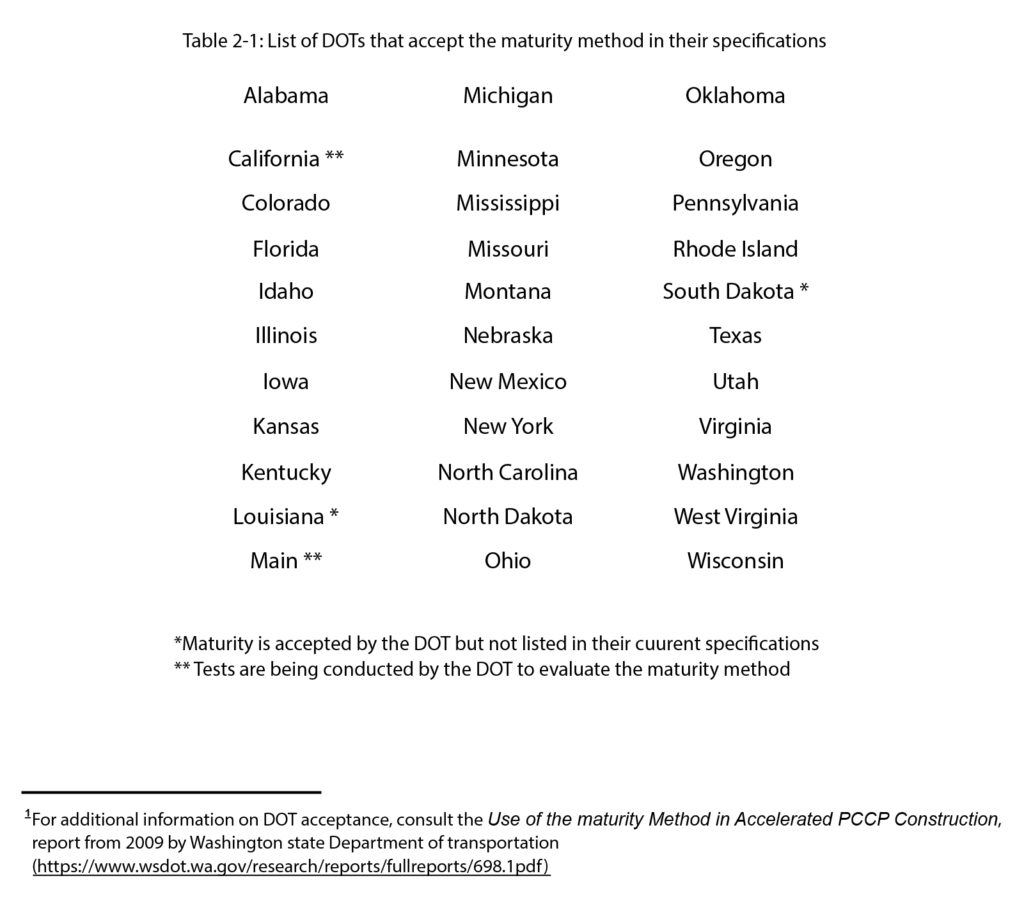

DOT: The maturity method is widely adopted by most of the DOT’s in the United States. As of January 2018, 29 states accept maturity as one of the testing methods in their specifications. A list of those states is presented in Table 2-1. The specifications in regards to maturity change per DOT as some mandate the use of the maturity method, while others simply accept it as an alternative to field-cured specimens or use it only for specific applications. Other states are currently in the process of implementing the method for future revisions.

Canada

CSA A23.1/A23.2: Concrete Materials and Methods of Concrete Construction/Test Methods and Standard Practices for Concrete

South America

NCH 170: Hormigon- Requisitos generals (Concrete- General requirements)

Europe

Multiple European countries allow for the maturity value to be used as a measurement for in-place strength by specifying maturity in their specific standards. The three standards that are generally used as a guide for measuring maturity:

EN 206-1: 2002, Concrete – Part 1: Specification, performance, production and conformity

BS EN 13670: Execution of concrete structures

NEN 5970: Determination of Strength of Fresh Concrete with the Method of Weighted Maturity

Comparing Maturity to Other Strength Methods

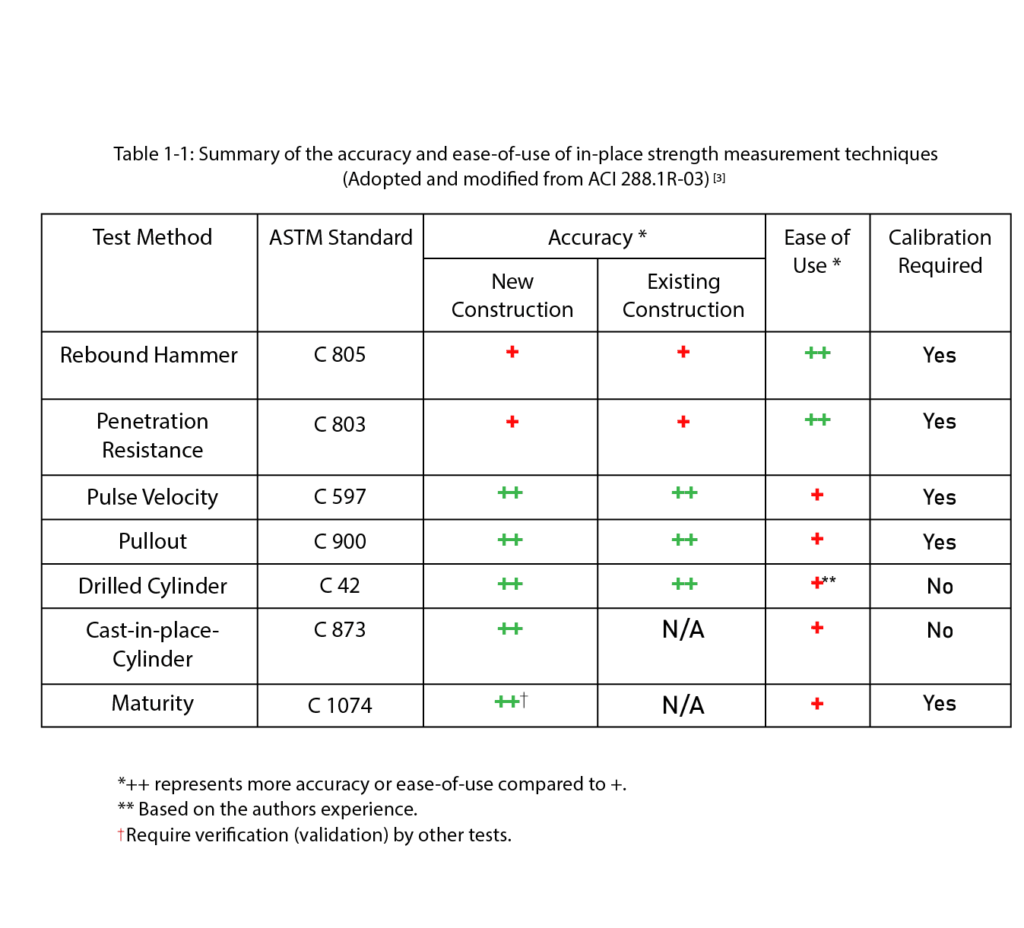

With the exception of the maturity method, all of the other methods have some limitations regarding the applicable range of compressive strength and/or location of the tests. Table 1-1 presents the accuracy, ease of use, and required specifications for different in-place strength monitoring methods. Table 1-1 was adapted and modified from ACI 288.1R; since the last release of this ACI guide in 2003. As a result, new developments in technologies have made most of these methods easier to use, in particular the maturity method. Even though a large range of in-place techniques is available to contractors that measure the in-place strength, the preferred method is still, in most cases, the break tests. Lately, concrete maturity measurement has largely gained popularity in North America, as well as throughout the world, albeit at a slower pace. It is the preferred method for a wide variety of projects and applications.

**Editors Note: This post was originally published in September 2018 and has been updated for accuracy and comprehensiveness on June 12th, 2023.