Mass Concrete and its Relationship With Temperature

Mass concrete pours are becoming more and more present in the construction industry. As our ambition grows, the size of our concrete structures grow with it.

Mass concrete pours are becoming more and more present in the construction industry. As our ambition grows, the size of our concrete structures grow with it.

As society continues to grow, so does infrastructure. With this being the case, concrete pours have also seen a change. Mass concrete refers to concrete pours that involve large structures. The following information covers everything from the basics of mass concreting to the impact of temperature on concrete.

When designing a construction project, a key consideration is the concrete mix itself. Concrete properties must be carefully managed to ensure durability and performance. The materials used in mixing concrete react with each other and produce heat through hydration. If this heat is not properly controlled, concrete cracking can occur. This heat rise causes larger-than-normal temperature differentials, which can be addressed through temperature sensors and cooling methods to regulate heat and maintain quality. This heat generation can be divided into the Pre-Induction Phase, where water first encounters the mixture, the Dormant Period, where the concrete begins to be workable in the early stages of hydration, the Strength Gain Phase, where it begins to harden, and the Steady State Phase, where the concrete temperature begins to stabilize, and hydration slows as strength is gained. Careful planning and techniques are required when pouring concrete, as ambient temperatures can further impact concrete stability.

As concrete cures, the core of the concrete element is where the maximum temperature occurs. Since the element cools from the outside in, the core may take years to fully settle. During this phase, the main issue is Delayed Ettringite Formation (DEF). This is where the ettringite does not form when required and leaves the element weaker. This is a negative byproduct of when an element’s temperature is too high and prevents the needed ettringite formations from occurring. The results will only show years later as the absence of the correct formations will cause cracks and concrete expansion, severely impacting the elements’ strength. DEF is a concern when the concrete temperature exceeds 158°F (70°C) and will cause issues with durability and service life. Ettringite is a normal process that occurs during the hydration phases of cement. It aids in preventing the quick stiffening of the concrete, allowing for better workability.

When the concrete begins to cool, there is quite a large differential between the hottest point and the coolest point. There are other factors to consider as well! For example, the outside ambient temperature which drastically impacts the surface while the core remains unaffected.

The issue is that there needs to be the lowest possible differential to ensure enough tensile strength to withstand the thermal stresses to avoid cracking. This cracking is due to how the different temperatures affect how the concrete moves in the element. It is because the cooler regions tend to contract while the hotter regions expand. This movement causes internal stresses and cracks, which are directly affected by the coefficient of thermal expansion. It represents the change in the size of the concrete related to the change of temperature. The lower the coefficient, the lower the volume change associated with heat rise, making the temperature differential larger. Concrete temperature differentials directly affect the strength of the element. As such, it is the mitigation of this difference that is the goal of workers.

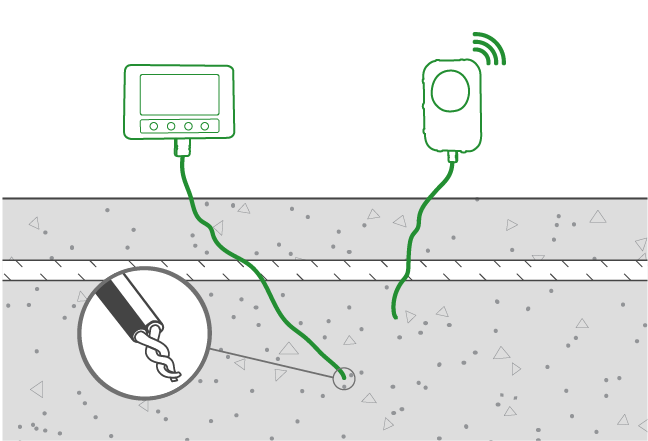

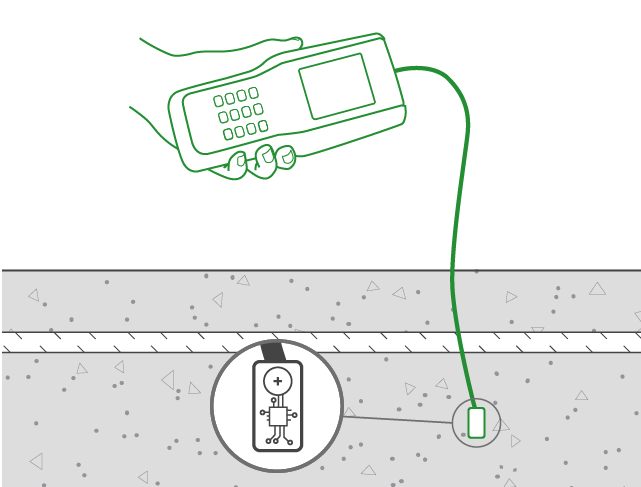

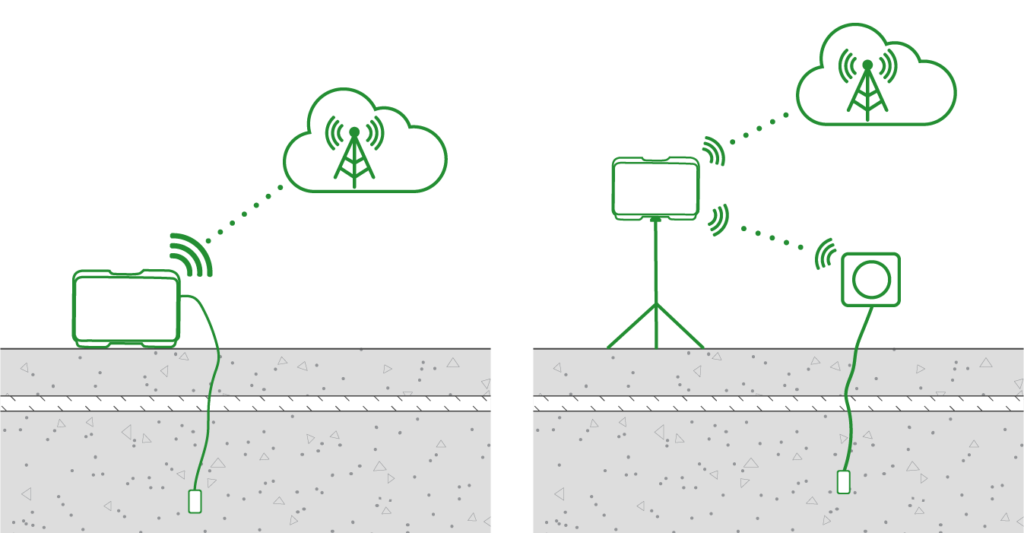

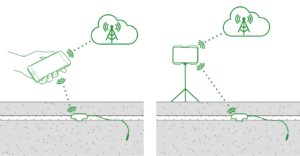

No matter what kind of project you are working on, you can achieve great results and ensure quality with a thermal control plan. If properly developed and executed, thermal control plans will stop concrete cracking and shrinkage, ensure adequate concrete strength gain, and prevent other quality-related issues with your concrete. To get the most accurate concrete temperature readings in the fastest possible time, use SmartRock® wireless concrete sensors. Take control of your concrete, avoid thermal cracking, achieve huge cost-savings, and move your projects along faster!

The required number of sensors per jobsite solely depends on the job itself, as there is no correct answer. The shape of the concrete element is another point of contention when deciding how many sensors are needed. However, the actual number is up to the engineer. A factor to take into consideration is the length of the pour. The timing of the utilization of concrete can cause many different temperatures and measurement points. The combination of sensors and restraints is used to help the concrete cure effectively. The role of restraints is to help the concrete retain its shape during the curing process. The shape of the restraints has a heavy influence on the maximum and minimum temperatures of the element. Thus affecting the number of necessary sensors.

Concrete cannot regulate its temperature independently because its core and surface of the concrete element experience different temperatures and behaviors. To address this, temperature regulation protocols must be followed to promote normal temperature readings. Methods such as cooling pipes, liquid nitrogen, and cooling of coarse aggregates are taken to manually cool the concrete element. In the past, ice was sometimes added to the mixture to cool it down. However, this would change the water content within the concrete, thus changing its behavior. Newer methods, such as using liquid nitrogen, bypass the issue of changing the water content. With this method being expensive, it also reduces the carbon footprint as less energy is used with transportation than ice and it needs no temperature regulation. A more efficient way is not to add liquid nitrogen to the mix directly but to cool down the coarse aggregates on a conveyor belt. The utilization of cooling pipes is another approach as pipes are pre-installed into the pouring area and allow for complete control over the concrete elements’ temperature. Keeping the temperature gradient minimal in a mass element is key to achieving a durable concrete structure.

Before construction begins, an adequate thermal plan must be in place to ensure the efficiency and quality of the concrete element. To develop a good thermal plan, one must first understand the factors affecting the jobsite such as ambient temperature, the dimensions of the project, mixture design, and others. Following this, there must be a good estimate of the adiabatic temperature rise of the concrete and the placing temperatures. Following the pour, all other variables must be calculated and carefully considered when deciding on cooling methods. Next is the curing process, which can be strenuous without the correct sensors or materials. Should the planned steps be followed, the concrete element should have longevity and durability for any situation.