Precisely monitor the temperature of your concrete structures under any conditions

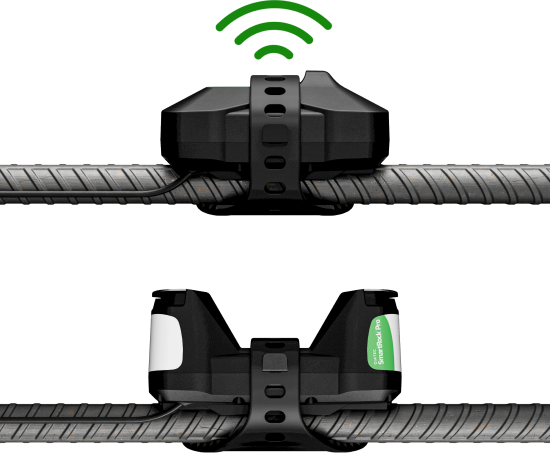

Collect real-time in-situ concrete strength data through maturity-based sensors

Maturity-Based Concrete Strength Monitoring

Self-Calibrating Concrete Strength Monitoring

AI-powered precision for every concrete mix for the Producers

Instant ROI

AI-Powered Decision Making

Drive Sustainability

Core Quality Control

Corrosion detection in concrete reinforcement

Concrete quality detection lab equipment

Experts revolutionizing the construction industry

Stay on the cutting edge of concrete tech

Save the date and join us at future events and conferences

Durability is a critical property of concrete that determines its ability to withstand environmental conditions and maintain its integrity over time. In Saudi Arabia, where structures are exposed to harsh climates, ensuring the durability of concrete is essential. In this blog, let’s discuss the importance of durability testing of concrete and the methods used to ensure long-lasting concrete structures in Saudi Arabia.Importance of Durability Testing Durability testing is essential for assessing the long-term performance of concrete. It helps identify potential issues such as cracking, spalling, and corrosion, which can compromise the structural integrity and safety of buildings and infrastructure. By conducting durability tests, engineers can ensure that the concrete meets the required standards and can withstand the environmental conditions it will be exposed to. Common Durability Tests There are various methods to assess the durability of concrete: Best Practices for Ensuring Durability Use of Quality Materials Using high-quality materials is crucial for ensuring the durability of concrete. Select aggregates that are clean, well-graded, and free from impurities. The type and quality of cement used can also impact the durability of the concrete. Proper Mix Design A well-proportioned mix design is essential for achieving durable concrete. The mix should have the right balance of cement, aggregates, and water. It…

Concrete production is essential to infrastructure development, but its environmental cost is significant. While construction industry contributes to 11% of global CO2 emissions, concrete is responsible for most of that (i.e. 8%). If it was a country, concrete would have ranked 3rd after US and China in terms of global GHG emissions. The majority of CO₂ emissions in the industry stem from the manufacturing of cement, specifically during the calcination of limestone in kilns and the combustion of fossil fuels. Each ton of cement produced generates nearly a ton of CO₂, making it a substantial contributor to global warming. This challenge is compounded by: The urgency to address CO₂ emissions has driven the industry toward innovative solutions, with Environmental Product Declarations (EPDs) emerging as a cornerstone of transparency and accountability. Role of Environmental Product Declarations (EPDs) Environmental Product Declarations (EPDs) serve as a powerful tool to improve transparency in the environmental impact of concrete products. Similar to the nutrition labels on food that provide for example the amount of sugar intake per serving, these standardized EPD documents provide quantifiable information on the environmental performance of a product across its life cycle, including Global Warming Potential (GWP) that is measured in CO2 equivalent weight. Key benefits…

Curing is a vital process in concrete construction that ensures the concrete achieves its desired strength and durability. In Türkiye, where cold temperatures can pose significant challenges, understanding the cold-curing process is essential. In this blog, let’s explore the best practices for curing concrete in cold weather conditions prevalent in Türkiye.Importance of the Cold CuringThe cold-curing process involves maintaining adequate moisture and temperature in the concrete during its early stages of hydration, especially in cold weather. A proper cold-curing process is crucial for several reasons: Challenges of Cold Weather Concreting Cold weather can significantly slow down the hydration process, leading to delayed strength gain and increased vulnerability to freezing. If the water in the concrete mix freezes, it can cause expansion and cracking, compromising the structural integrity of the concrete. As such, it is important to ensure that your concrete is in ideal environmental conditions to achieve an optimal cold-curing process.Want to improve your cold weather concreting? Get the details here!Best Practices for Cold CuringConclusion A proper cold-curing process is essential for achieving strong and durable concrete structures in Türkiye. By following best practices and using appropriate methods, builders can ensure the quality and longevity of their concrete projects. Want expert advice on improving…

Visit our careers page to learn about our award-winning culture and our open positions.

Watch how SmartRock can work for you.