SmartRock® Plus

A Value-Added Solution for Concrete Ready-Mix Producers

Empower contractors, know your concrete, win more business

Empower contractors, know your concrete, win more business

SmartRock Plus is a value-added solution offered by high-quality ready-mix producers that enables their contractors to see real-time concrete temperature and strength data. Once contractors have installed the fully embedded wireless sensors onsite, they can assign their producer’s pre-calibrated mixes to their sensor. Data obtained on the jobsite gives the producer visibility and valuable insight on their mix performance, always providing full control to producers, displaying who uses their mixes with their proprietary information protected.

SmartRock Plus enables producers to achieve:

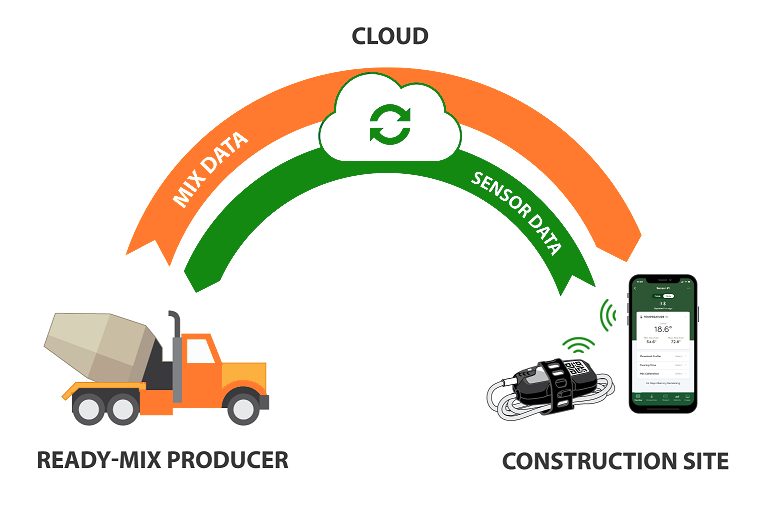

As an IoT solution, SmartRock Plus combines wireless sensors with mobile and cloud-based applications to make field data available for ready-mix producers. This data can be used to analyze jobsite and concrete mix performance.

In addition, ready-mix producers will benefit from:

Producers simply need to calibrate each mix for strength using the maturity method (ASTM C1074) and upload the data to the system. Contractors then find their producer in the SmartRock mobile app and request access to use their specific mix calibrations, which are continuously maintained by the SmartRock Plus producers. Once a mix is selected and the sensors are installed, contractors automatically obtain concrete temperature and strength information. This real-time data helps contractors optimize critical operations, such as formwork removal, post-tensioning, and opening roads to traffic, etc.

To become a SmartRock Plus partner, fill out our “get in touch” form on the SmartRock Plus product page and our team will contact you as soon as possible to discuss this value-added program with you.

With SmartRock Plus you will be able to pre-calibrate a variety of mixes for contractors. Contractors will not have to go through the calibration process as this will all be handled by the producers. This is an all-in-one solution for the contractors. In addition, producers have full control and the best understanding of their mixes, where you can expect up-to-date maturity calibrations.

Once you become a producer partner and you start calibrating mixes, those mixes’ names will appear in the list of available mixes for any SmartRock users in your region. Contractors can simply request access to your mix.

Yes, once a contractor requests access to a mix, they become one of your clients in your dashboard. You can now decide which mixes will be available for them to use as well as add or remove mix access for specific clients.

Save now and get free Giatec 360™ Premium access. Ends Dec 31. Don’t miss it!

Cut risk on mass concrete pours and get free Giatec 360™ Premium. Ends Dec 31. Don’t miss it!