Evaluating Concrete Quality with Electrical Resistivity Test

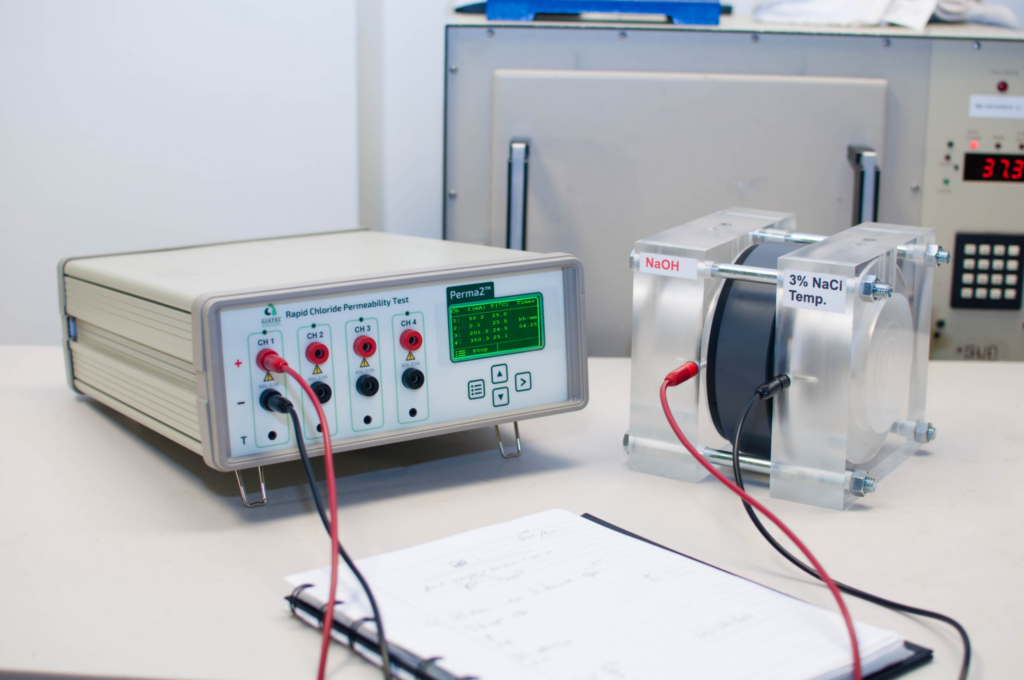

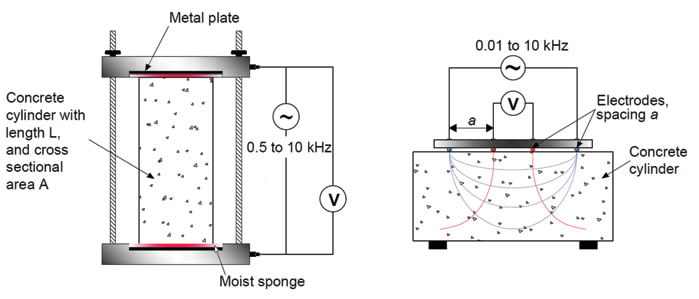

The fast-paced environment of the construction industry results in a constant search for better and more efficient ways to evaluate the quality of concrete. Despite the increase in modern knowledge regarding concrete research, current industry practices still rely on compressive strength testing to measure concrete quality. However, the results of a compressive test alone do not represent the quality or durability of the concrete. In this blog, learn about how concrete resistivity tests can help the industry as well as the different ways we can evaluate concrete’s durability through electrical resistivity testing. The Problem With the RCP Method When strength is the only quality specification, contractors concentrate their efforts on delivering a material that is compliant with strength requirements. This ultimately does not represent the durability of the concrete. As a result, multiple tests for obtaining and understanding durability by measuring concrete’s ability to resist chloride penetration have widely become accepted. This method, commonly known as RCP, measures chloride penetration in a range from high to negligible. The “ASTM C1202: Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration” standardizes this process. However, not only is this approach labor-intensive but also time-consuming. The test itself…